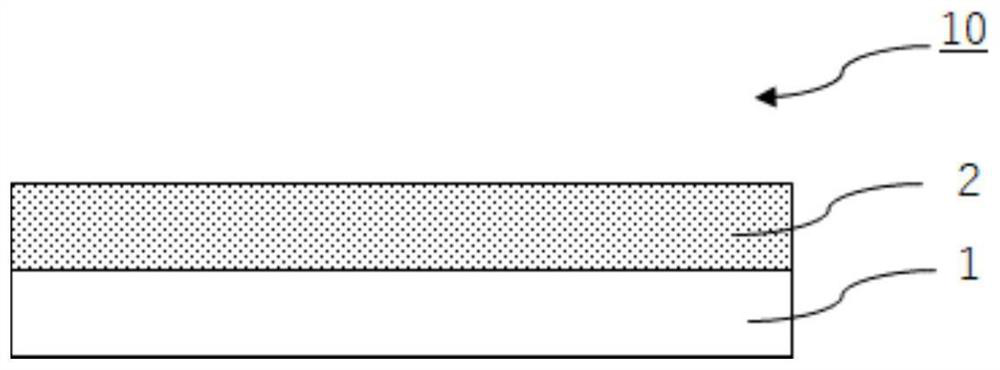

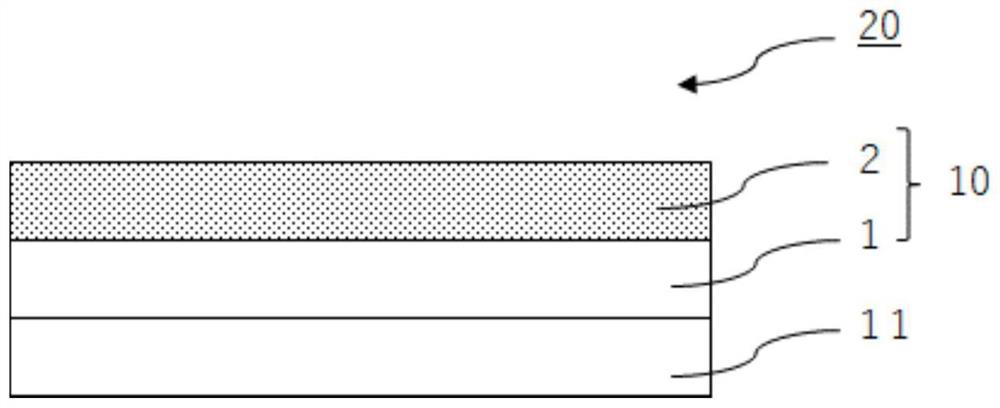

Colored film and colored adhesive tape

A technology for colored films and adhesive tapes, applied in the direction of film/sheet-like adhesives, adhesives, etc., can solve the problem of peeling, difficulty in taking into account alcohol resistance and curl resistance. The problem of low film adhesion and other problems, to achieve the effect of suppressing curling and good alcohol resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

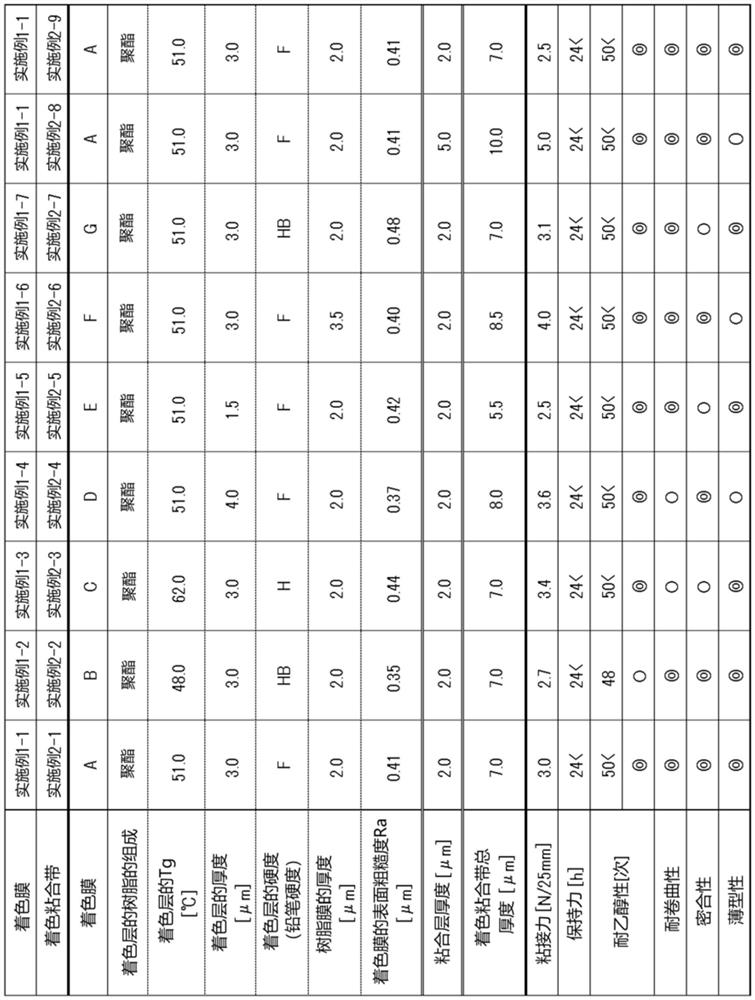

Embodiment 1-1

[0142] Toray polyester film Lumirror 2F51 (thickness: 2.0 μm, tensile strength 3 N / 10 mm) was gravure-coated with black ink A so as to have a dry thickness of 3.0 μm, and aged at 40° C. for 1 day to obtain a black ink coating Cloth film A (colored film A). The reaction cured product of the polyester polyol resin A of the black ink A and the curing agent, that is, the glass transition temperature of the colored layer of the colored film A was 51.0°C. In addition, the glass transition temperature of a colored layer is a value measured using DSC in accordance with ISO 3146. The following is the same.

Embodiment 1-2

[0144] A black ink coating film B (colored film B) was obtained in the same manner as in Example 1-1, except that the black ink B was used instead of the black ink A. The reaction cured product of the polyester polyol resin B and the curing agent of the black ink B, that is, the glass transition temperature of the colored layer of the colored film B was 48.0°C.

Embodiment 1-3

[0146] A black ink coating film C (colored film C) was obtained in the same manner as in Example 1-1, except that the black ink C was used instead of the black ink A. The reaction cured product of the polyester polyol resin B and the curing agent of the black ink C, that is, the glass transition temperature of the colored layer of the colored film C was 62.0°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com