Metal solid state deposition device and method and material with metal layer on surface

A deposition device, metal layer technology, applied in additive processing, pressure inorganic powder coating, additive manufacturing, etc., can solve the problems of energy waste, inability to achieve uniform stress relief, limited use effect, etc., to achieve a wide range of applications, eliminate Effect of Coating Cracking Risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

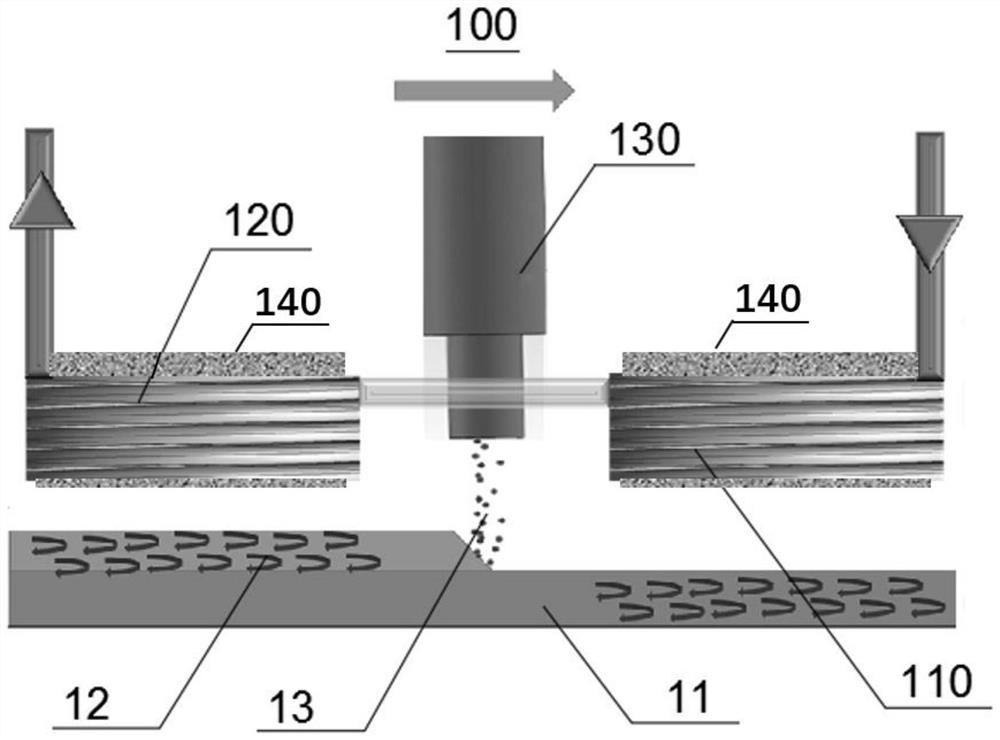

[0057] In this embodiment, the base body 11 is 45# steel, and the metal powder 13 is 316L stainless steel powder.

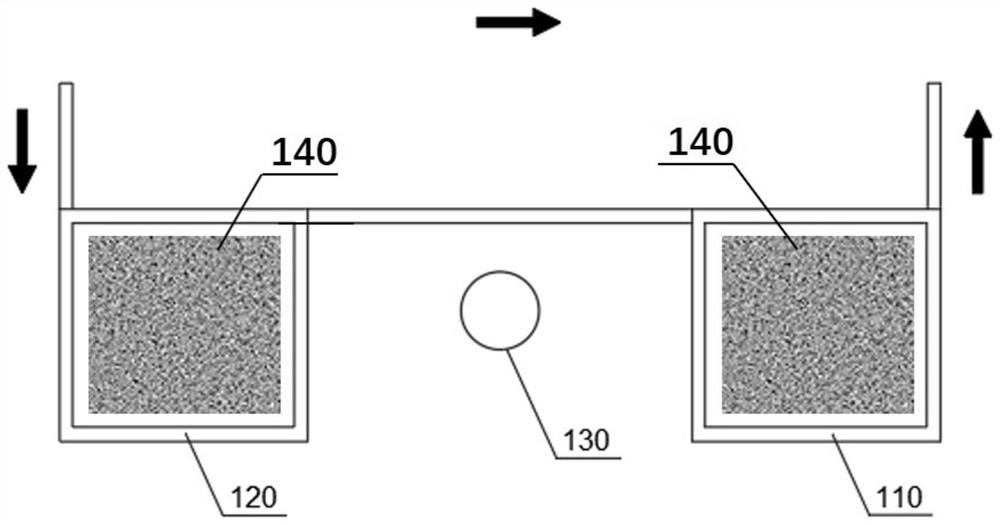

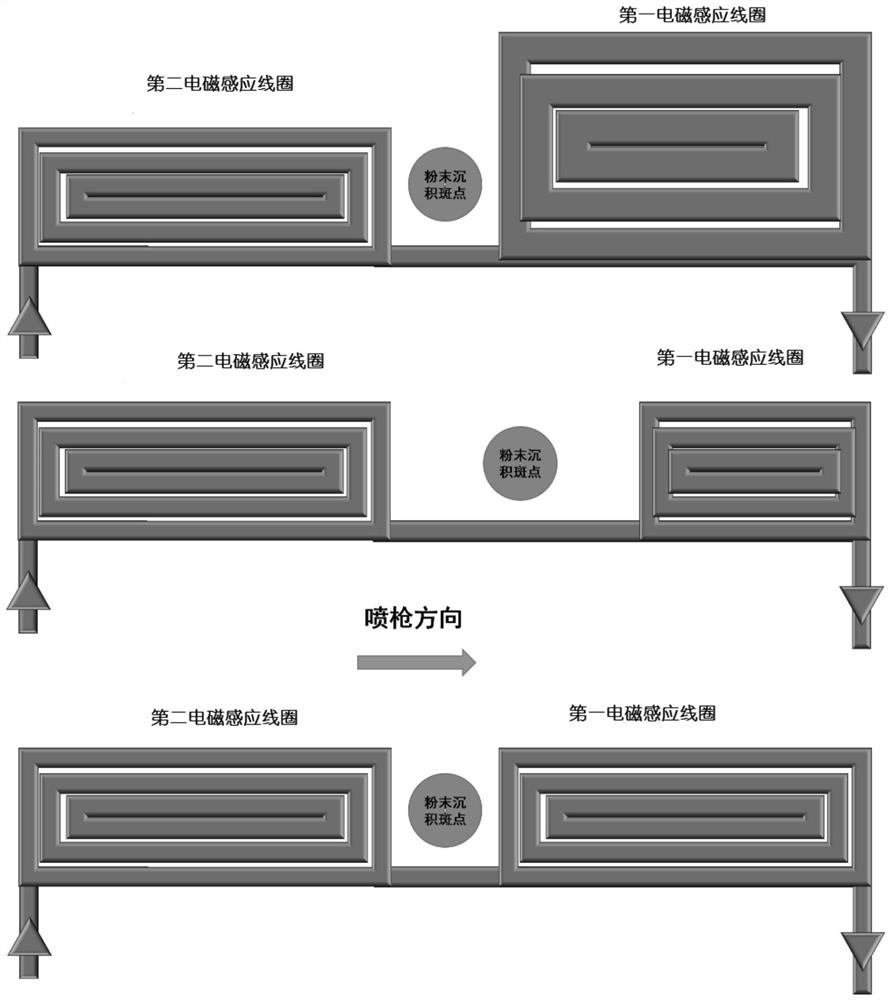

[0058] The Rafael nozzle 130 faces the surface of the substrate 11 at an included angle of 90 degrees, and the hollow channel of each electromagnetic induction coil faces the surface of the substrate 11. The Rafael nozzle 130 is linked with the electromagnetic induction coil, and the moving trajectories overlap to scan the surface of the substrate 11. .

[0059] The high-frequency current generated by the special power transformer (power 250KW, oscillation frequency 200KHz) is connected with the first electromagnetic induction coil 110 and the second electromagnetic induction coil 120 to form a strong alternating magnetic field; the magnetic field generated by the first electromagnetic induction coil 110 A magnetic circuit is formed with the area to be deposited, so that a vortex-like induced current is generated on the surface of the substrate 11, and the surfac...

Embodiment 2

[0067] This embodiment is basically the same as Embodiment 1, the only difference is that the oscillation frequency is 50KHz.

[0068] After testing, the bonding strength of the 316L coating prepared on the surface of 45# steel in this example is 62MPa, the thickness of the single-layer coating (the coating after scanning once on the surface of the substrate 11) can be greater than 0.3mm, and the overall coating (on the substrate 11) thickness can be greater than 0.3mm. The thickness of the overall coating after multiple surface scans can be greater than 5 mm, the entire deposition body does not appear transverse / longitudinal cracks, and the coating porosity is less than 0.4%.

Embodiment 3

[0070] This embodiment is basically the same as Embodiment 1, the only difference is that the oscillation frequency is 400KHz.

[0071] After testing, the bonding strength of the 316L coating prepared on the surface of 45# steel in this example is greater than 80MPa, the thickness of the single-layer coating (the coating after scanning the surface of the substrate 11 once) can be greater than 0.2 mm, and the overall coating (on the substrate 11) thickness can be greater than 0.2 mm. The thickness of the overall coating after multiple scans on the surface can be greater than 3mm, the entire deposition body does not appear transverse / longitudinal cracks, and the coating porosity is less than 0.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com