Preparation method of animal-derived mink cashmere modified fiber

A technology of modified fiber and animal source, applied in plant fiber, flame retardant fiber, fiber treatment, etc., can solve the problems of protein component damage, affecting fiber performance, protein component loss, etc., achieve high dry breaking strength, increase additive Dosage, the effect of reducing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

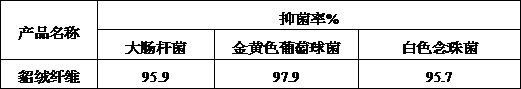

Embodiment 1

[0032] Embodiment 1: a kind of preparation method of animal source mink cashmere modified fiber, described preparation method comprises the following steps:

[0033] (1) Pretreatment of mink down

[0034] Put 1kg of mink wool in the reaction kettle, bath ratio 1:10, heat up to 98°C, add 20g of refining agent, keep warm for 50 minutes, remove grease and stains, drain, wash with hot water once, hot water temperature 60°C, cold water Wash 3 times, dehydrate and dry.

[0035] (2) Crushing of mink

[0036] The mink hair dried in step (1) is frozen to minus 50°C in a low-temperature freezer, and the frozen mink hair is quickly taken out and placed in a pulverizer to be pulverized into a powder with a particle size of 100nm.

[0037] (3) Preparation of mixed dispersion

[0038] Put 100g of natural white zeolite powder and 50g of velvet powder prepared in step (2) into a 2000mL beaker, add 900g of distilled water at a temperature of 56°C into the beaker, add 5g of xanthan gum, stir...

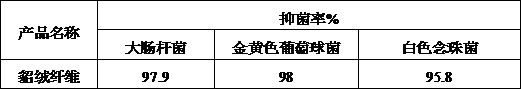

Embodiment 2

[0055] Embodiment 2: a kind of preparation method of animal source mink cashmere modified fiber, described preparation method comprises the following steps:

[0056] (1) Pretreatment of mink down

[0057] Put 1kg of mink wool in the reaction kettle, bath ratio 1:10, heat up to 98°C, add 20g of refining agent, keep warm for 50 minutes, remove grease and stains, drain, wash with hot water once, hot water temperature 60°C, cold water Wash 3 times, dehydrate and dry.

[0058] (2) Crushing of mink

[0059] The mink hair dried in step (1) is frozen to minus 50°C in a low-temperature freezer, and the frozen mink hair is quickly taken out and placed in a pulverizer to be pulverized into a powder with a particle size of 100nm.

[0060] (3) Preparation of mixed dispersion

[0061] Put 100g of natural white zeolite powder and 50g of velvet powder prepared in step (2) into a 2000mL beaker, add 900g of distilled water at a temperature of 56°C into the beaker, add 8g of xanthan gum, stir...

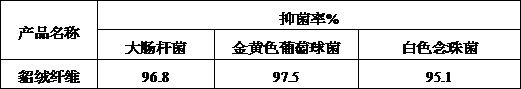

Embodiment 3

[0078] Embodiment 3: a kind of preparation method of animal source mink cashmere modified fiber, described preparation method comprises the following steps:

[0079] (1) Pretreatment of mink down

[0080] Put 1kg of mink wool in the reaction kettle, bath ratio 1:10, heat up to 98°C, add 20g of refining agent, keep warm for 50 minutes, remove grease and stains, drain, wash with hot water once, hot water temperature 60°C, cold water Wash 3 times, dehydrate and dry.

[0081] (2) Crushing of mink

[0082] The mink hair dried in step (1) is frozen to minus 50°C in a low-temperature freezer, and the frozen mink hair is quickly taken out and placed in a pulverizer to be pulverized into a powder with a particle size of 100nm.

[0083] (3) Preparation of mixed dispersion

[0084] Put 100g of natural white zeolite powder and 50g of velvet powder prepared in step (2) into a 2000mL beaker, add 900g of distilled water at a temperature of 56°C into the beaker, add 10g of xanthan gum, sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com