Special-shaped blank surface quality control method, system and device

A technology of surface quality and control methods, applied in neural learning methods, biological neural network models, image analysis, etc., can solve the problems of lack of control measures for defects, lack of physical size measurement of special-shaped blanks, etc., to achieve physical size measurement and surface defects. The effect of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

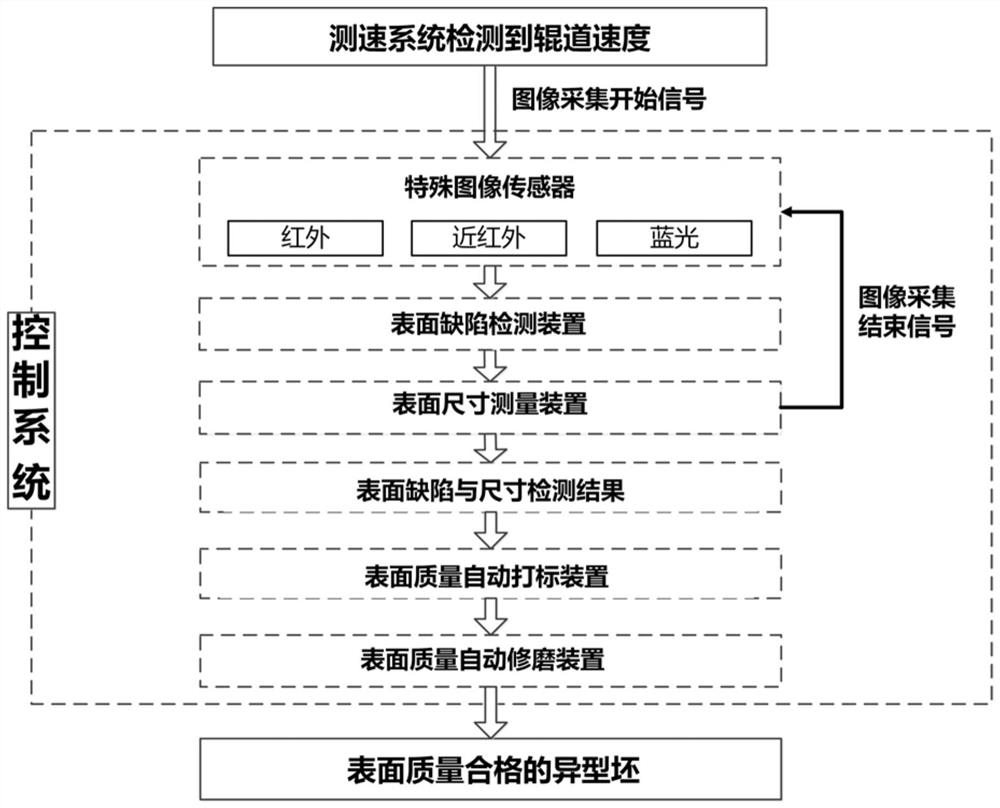

[0040]Embodiment 1 of the present invention proposes a method for controlling the surface quality of a special-shaped blank, which is based on the fusion of dual-channel image line structured light and a deep learning algorithm, and simultaneously realizes the physical size measurement and surface defect detection of the special-shaped blank.

[0041] like figure 1 It is a flow chart of a method for controlling the surface quality of a special-shaped blank in Embodiment 1 of the present invention;

[0042] Acquiring a first image for measuring the surface size of the special-shaped blank and acquiring a second image for detecting the surface defect of the shaped blank; in the present invention, the infrared and near-infrared channels in the imaging module are used for collecting the surface size of the shaped blank. The first image of ; the second image for surface defect detection of the special-shaped blank is collected through the blue light channel in the imaging module. ...

Embodiment 2

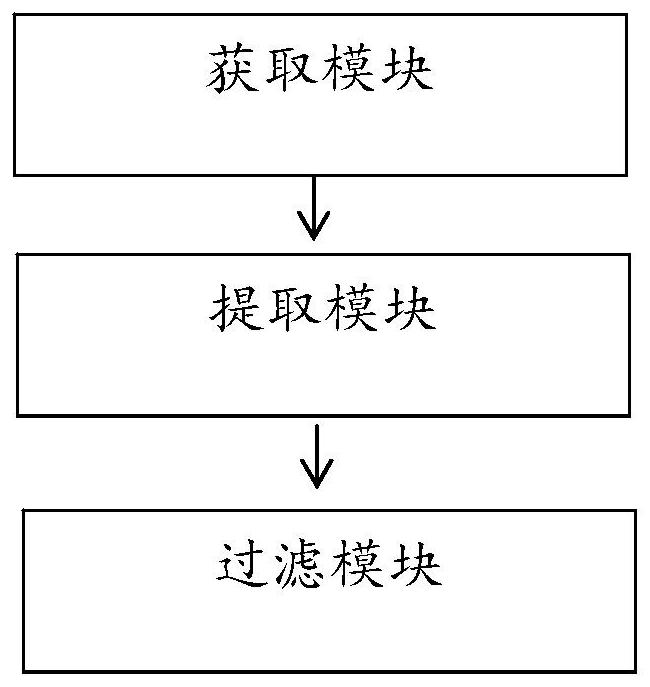

[0059] A method for controlling the surface quality of a special-shaped blank proposed based on Embodiment 1 of the present invention. Embodiment 2 of the present invention also proposes a special-shaped blank surface quality control system, such as image 3 It is a schematic diagram of a special-shaped blank surface quality control system according to Embodiment 2 of the present invention; the system includes an acquisition module, an extraction module and a filter module;

[0060] The acquisition module is used for acquiring a first image for measuring the surface size of the profiled blank and acquiring a second image for detecting the surface defect of the profiled blank;

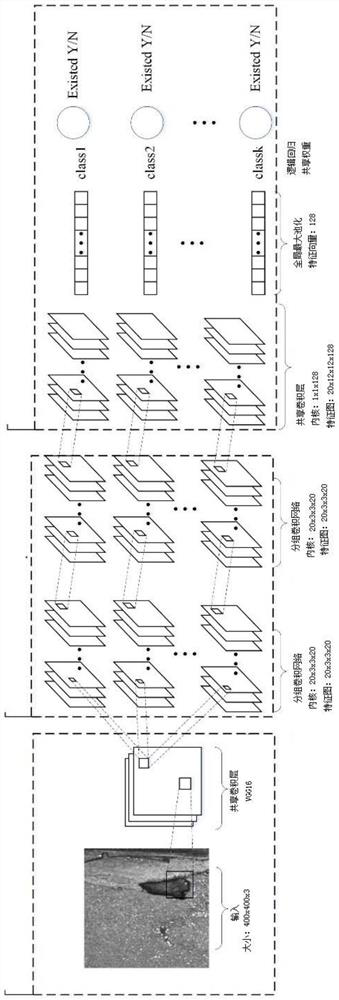

[0061] The extraction module extracts the common features in the second image through the shared convolutional network, and then uses the image including the common features as the input of the first grouped convolutional network, sets the convolutional layer according to the number of defect categories...

Embodiment 3

[0077] A method for controlling the surface quality of a special-shaped blank proposed based on Embodiment 1 of the present invention. Embodiment 3 of the present invention also proposes a profiled blank surface quality control device, such as Figure 4 It is a schematic diagram of the connection of a special-shaped blank surface quality control device in Embodiment 3 of the present invention, and the device includes an imaging module and a host computer;

[0078] The imaging module is connected to the first input port of the upper computer, and the encoder is connected to the second input port of the upper computer; the output port of the upper computer is connected to the input port of the coding and marking machine, and the output port of the coding and marking machine is connected to Grinding machine.

[0079] The imaging module collects the first image for measuring the surface size of the special-shaped blank through infrared and near-infrared channels, and collects the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com