Composite seasoning salt and preparation method thereof

A seasoning salt and umami technology, which is applied in the field of compound seasoning salt and its preparation, can solve the problems of affecting the taste of seasoning salt, easy caking of products, moisture regain, etc., achieve good formability and solubility, improve anti-caking ability and stability Sex, salty pure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

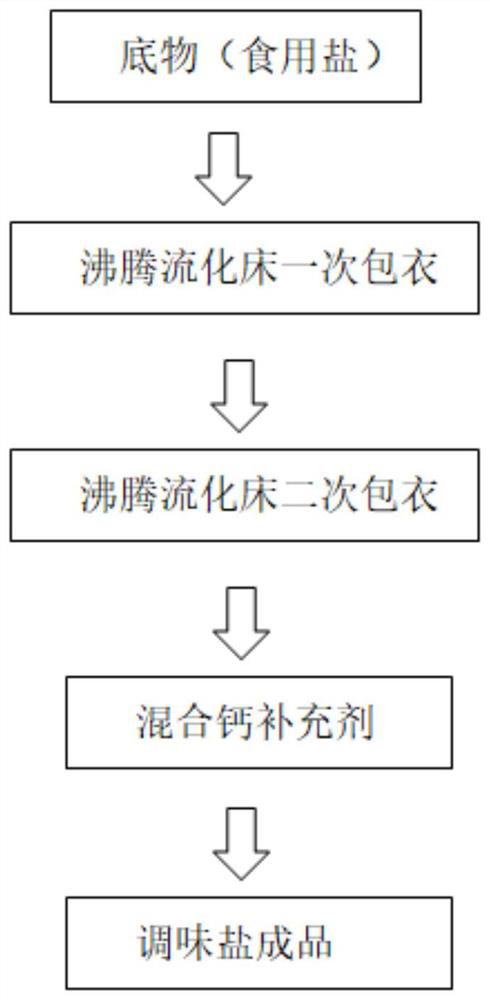

[0046] The present invention also provides the preparation method of compound seasoning salt, and the preparation of its main component comprises the following steps:

[0047] According to the composition of the first coating, each material is mixed and dissolved in water to prepare a first coating solution;

[0048] According to the composition of the second coating, each material is mixed and dissolved in water to prepare a second coating liquid;

[0049] Use the first coating liquid to coat the edible salt for the first time, and dry it to form a first coating; use the second coating liquid to perform a second coating on the surface of the first coating coat and dry to form a second coat.

[0050] In one example, the edible salt was dried prior to the first coating. Further, the step of drying treatment includes: taking edible salt, heating and stirring for 5min-6min with medium and small fire (for example, the power is 400W~1400W, the temperature is 60℃~120℃) to evaporat...

Embodiment 1

[0060] The present implementation provides a compound seasoning salt, its formula and preparation process (see the process flow diagram, see figure 1 )as follows:

[0061] 1. Recipe

[0062] (1) Substrate and feed liquid formula:

[0063] 1.1 Substrate: edible salt (100%).

[0064] 1.2 Feed liquid 1 (for primary coating) (by weight): 7.0 parts of brewed soy sauce, 10 parts of kelp juice, 5.0 parts of water, 3.0 parts of fermented vinegar, 1.0 parts of yeast extract, 1.0 parts of bonito extract part, 1.0 part of scallop extract, 1.0 part of soybean extract.

[0065] 1.3 Feed liquid 2 (for secondary coating) (by weight): 65 parts of water, 22 parts of edible salt, 10.0 parts of trehalose, 3.0 parts of maltodextrin, and 1.5 parts of gum arabic.

[0066] (3) The weight ratio of the bottom material liquid (in parts by weight): substrate: material liquid 1: material liquid 2=6:3:4.

[0067] (3) Finished product formula: add 0.6% tricalcium phosphate to the sample prepared from ...

Embodiment 2

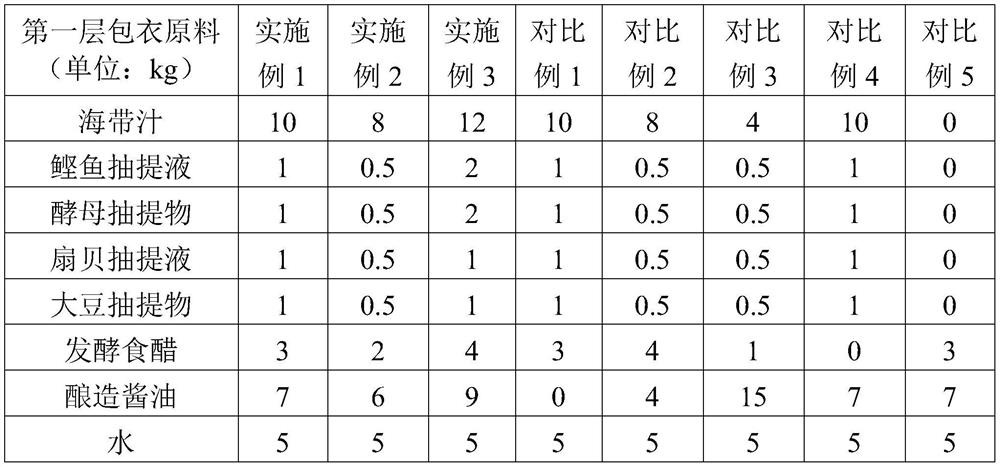

[0079] This example is an investigation of the influence of the ratio of each material in the compound seasoning salt on the performance.

[0080] The compound seasoning salts of Examples 2 to 3 and Comparative Examples 1 to 5 were prepared according to the same formula and preparation as in Example 1, and the main differences were shown in Tables 2 to 3 below:

[0081] Table 2

[0082]

[0083] table 3

[0084]

[0085]

[0086] The composite seasoning salts of Examples 1 to 3 and Comparative Examples 1 to 5 were tested for their performance from the aspects of coating uniformity, formability and solubility, and the results are shown in Table 4.

[0087] Table 4

[0088]

[0089] As can be seen from Table 4, the composite seasoning salt coating uniformity, formability and solubility in water prepared by the method of the present invention all have significant advantages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com