Dynamically vulcanized thermoplastic elastomer composite material composition as well as preparation method and application thereof

A thermoplastic elastomer and composite material technology, applied in the field of thermoplastic elastomer materials, can solve the problems of high strength and low permanent deformation performance, achieve high strength and improve the effect of crosslinking uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0097] Preparation of Block Polymer Composition 1:

[0098] In a 5-liter stainless steel stirred tank, under the protection of high-purity nitrogen, 2000g of cyclohexane / n-hexane mixed solvent, 265g of styrene and 0.2g of tetrahydrofurfuryl alcohol ether were added, and 2.9mmol of n-butyllithium was added at 55°C to initiate the reaction , and then carry out the first polymerization reaction for 15 min under the heating of a circulating water bath at 70 °C to complete the polymerization of styrene, and obtain a mixture containing S 1 the first polymerization system;

[0099] To the first polymerization system, 9.5 mmol of n-butyl lithium was added, followed by 115 g of styrene, and the second polymerization reaction was carried out at 70° C. for 15 min until the styrene was completely converted to obtain S 1 -S 2 and S 2 the second polymerization system;

[0100] To the second polymerization system, add 2.9 mmol n-butyllithium, then add 120 g of butadiene, and carry out th...

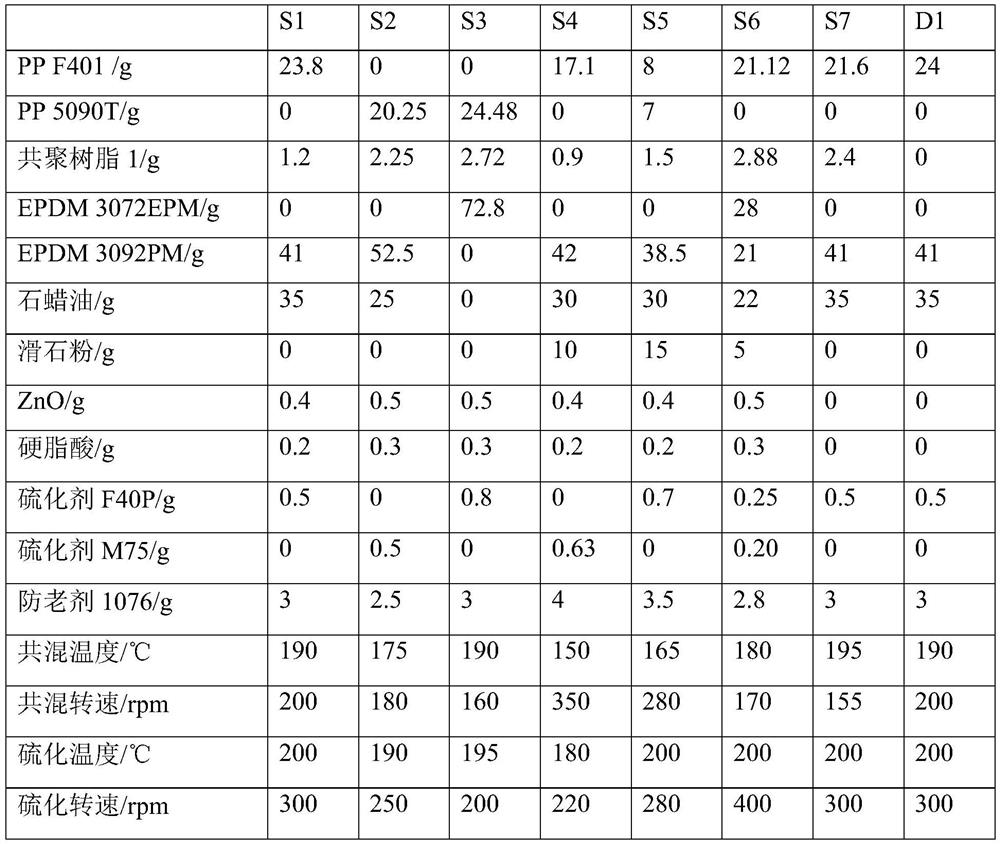

Embodiment 1

[0111] (1) Mix the mixture of homopolypropylene F401 and copolymer resin 1 (feeding speed is 4.1kg / h), EPDM 3072EPM (feeding speed is 2.4kg / h), paraffin oil (feeding speed is 2.4kg / h) 3.5kg / h) were added to twin-screw extruders (products of Coperion Machinery Co., Ltd., length-diameter ratio 56, screw diameter 35mm, equipped with underwater pelletizing system), at a temperature of 190 ° C and a rotation speed of 200 rpm. Blending to obtain a blended rubber, and then dicing the blended rubber underwater to obtain a blended rubber-plastic masterbatch;

[0112] (2) vulcanizing agent F40P and vulcanizing agent M75 are added in the above-mentioned blended rubber-plastic master batch to obtain mixed master batch; then mixed master batch (feeding speed is 6.5kg / h) and paraffin oil (feeding speed is 3.5 kg / h) in a twin-screw extruder, vulcanized to obtain vulcanized rubber, then the vulcanized rubber is subjected to underwater pelletizing to obtain the pellets of the dynamically vulca...

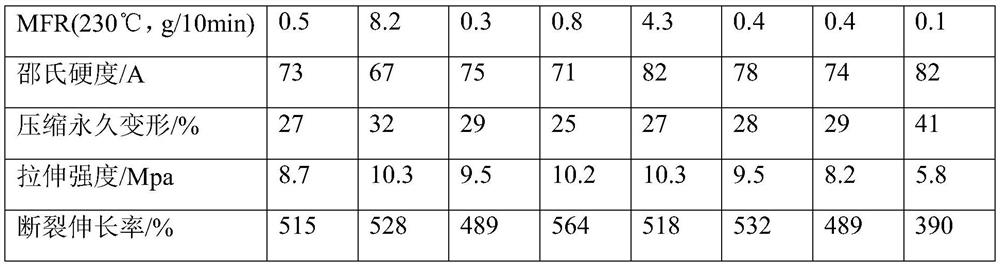

Embodiment 2-7

[0115] According to the method of Example 1, the difference is: the specific formula, processing technology and material properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com