Aluminum foil adhesive tape and preparation method thereof

A technology of aluminum foil tape and aluminum foil layer, which is applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., and can solve the problem of aluminum foil tape holding and adhesion reduction, refrigerators and other refrigerators Poor heat dissipation, thermal fatigue aging of aluminum foil tape and other problems, to achieve good cross-linking degree, reduce steric hindrance effect, and high adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

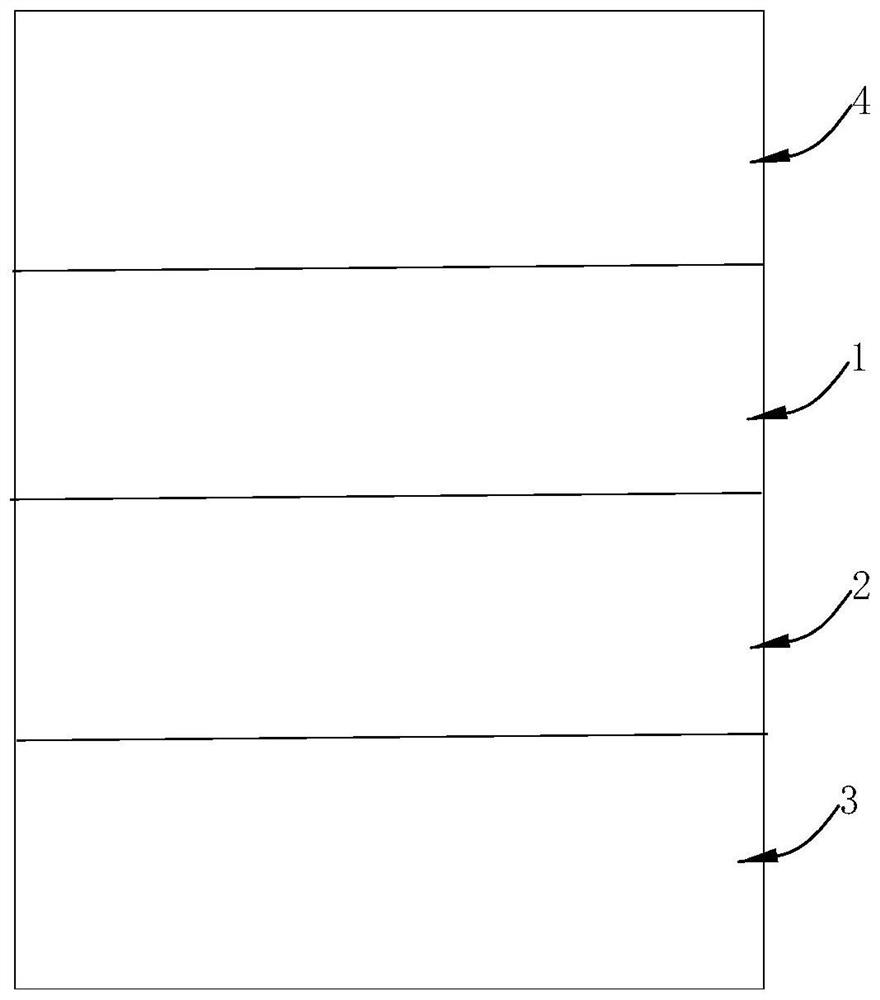

[0037] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

[0038] like figure 1 As shown, the aluminum foil tape of the present invention includes

[0039] an aluminum foil layer 1, having opposite first and second surfaces;

[0040] The first adhesive layer 2 is covered on the first surface of the aluminum foil layer 1, and the first adhesive layer 2 is an acrylic adhesive layer;

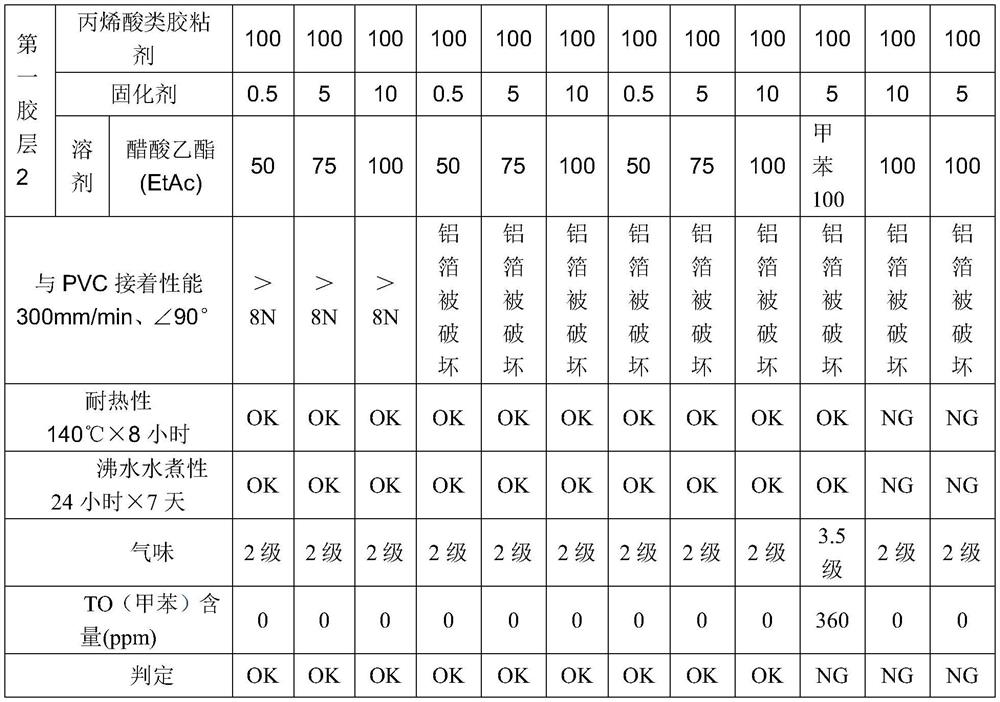

[0041] In parts by mass, the first adhesive layer 2 includes the following raw materials:

[0042] 100 parts of acrylic adhesive

[0043] Curing agent 0.5~10 parts

[0044] Solvent 50~100 parts

[0045] The curing agent is a modified polyisocyanate polymer;

[0046] The release layer 3 is covered on the first adhesive layer 2 for protecting the first adhesive layer 2;

[0047] The second adhesive layer 4 is covered on the second surface of the aluminum foil layer 1. In parts by mass, the second adhesive layer 4 inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com