Novel dynamic phase change material wall structure

A phase change material and wall structure technology, applied in the direction of walls, building components, heat exchanger types, etc., can solve the problems of pollution, large cooling energy consumption, etc., to optimize wall operation, save energy, and reduce efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

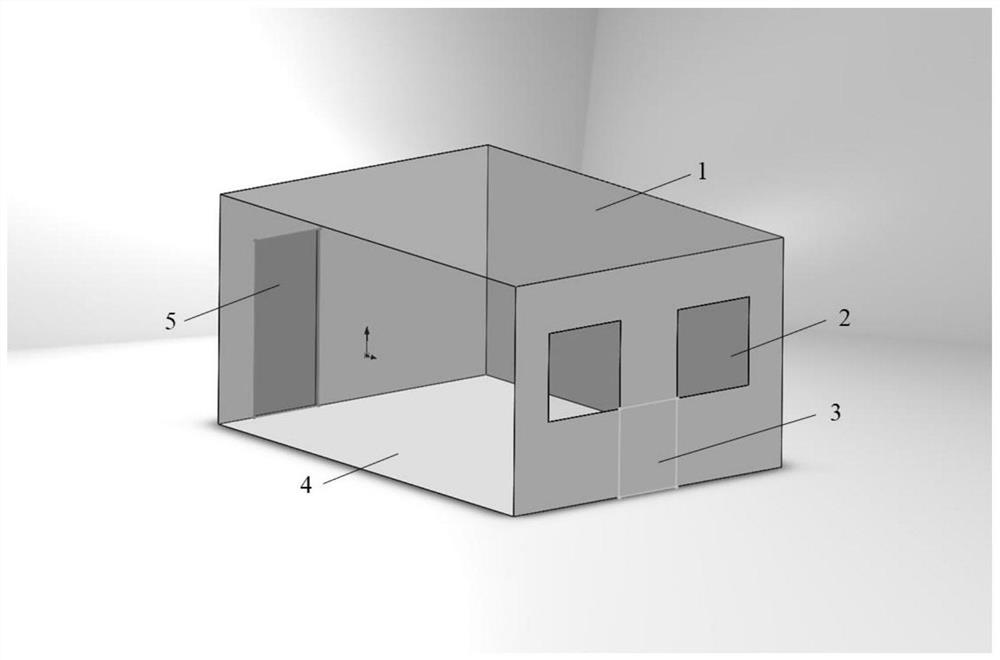

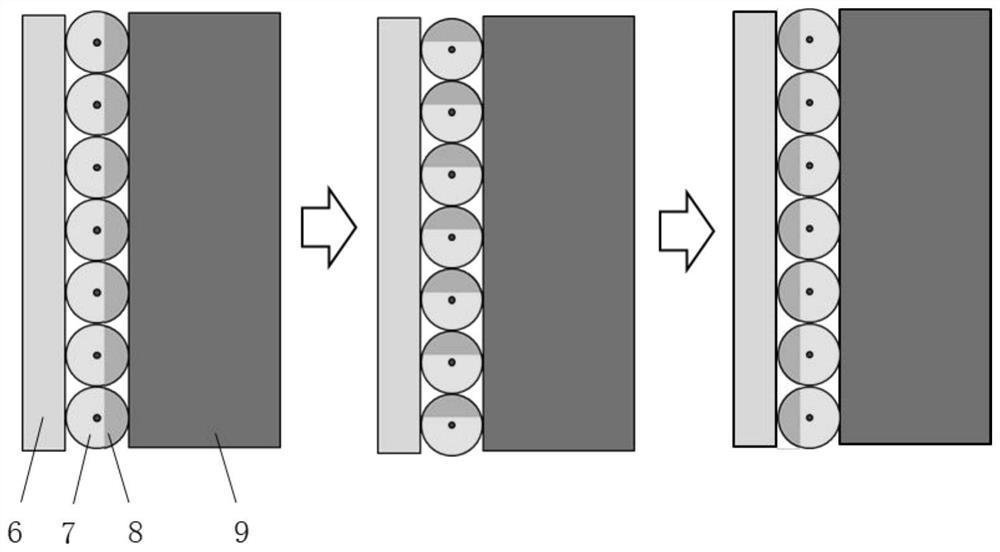

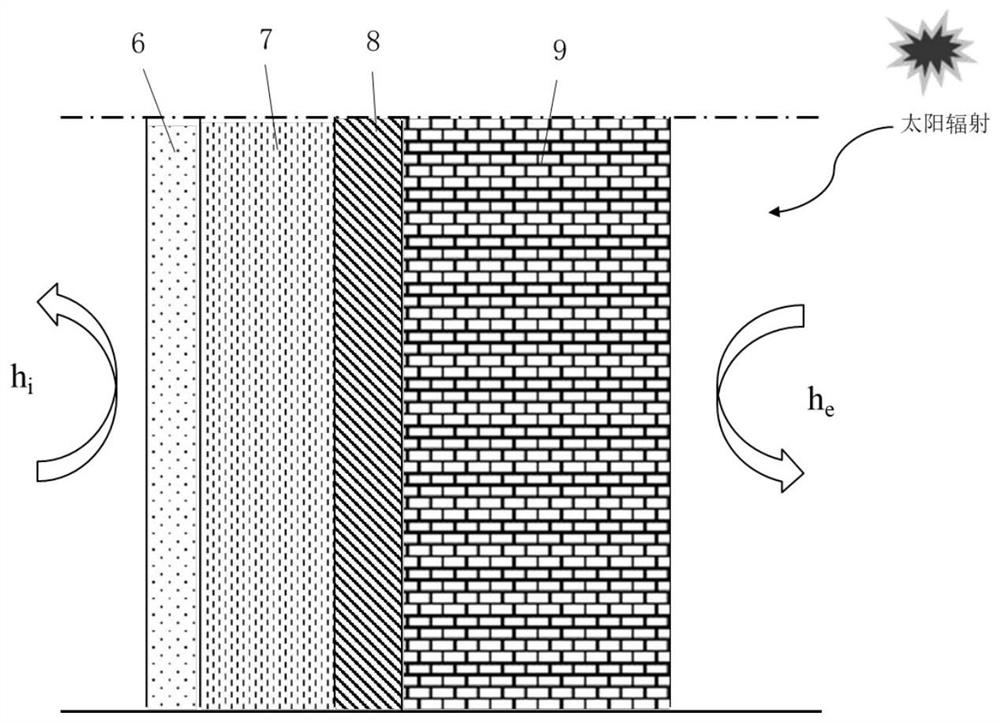

[0037] This embodiment provides a new type of dynamic phase change material wall structure that utilizes external heat sources to save energy in the building envelope. figure 1 1 in the room structure shown. The novel dynamic phase change material wall structure of the present invention, which utilizes external heat sources to save energy in the building envelope, includes a brick layer, and the brick layer is located at the outermost side of the entire wall body, covering the entire wall surface, such as figure 2 As shown in the figure, the inner side of the brick layer has a thermal insulation layer and a phase change material (PCM) layer, and the thermal insulation layer also covers the entire wall. , and also cover the entire wall. During the winter day and night, the positions of the phase change material (PCM) layer and the thermal insulation layer are different, such as image 3 and 4 As shown, the position of the phase change material (PCM) layer changes relative t...

Embodiment 2

[0040] This example compares the performance of the proposed wall structure with two similar wall structures, one without PCM and the other with fixed PCM position, called fixed (static) phase change material wall structure. Computational fluid dynamics (CFD) method is adopted and the experimental comparison shows that the CFD model can accurately simulate the coupling effect of heat transfer and air flow. By studying the phase transition and room temperature of PCM in two cities of Tianjin and Harbin within 24 hours in February, it is found that compared with the traditional thermal insulation wall without phase change material, the dynamic phase change material wall proposed by the present invention can save 89% respectively. % and 49% of external energy, keeping the room temperature in Tianjin and Harbin within the recommended range for human comfort. In contrast, the corresponding savings achieved by static PCM walls were 6% and 13%, respectively. By using only 0.32kg of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com