Gravity sliding power machine

A technology of power machine and gravity, applied in the field of gravity sliding power machine, can solve the problems of environmental pollution, noise, pollution and other problems of thermal energy technology, and achieve the effect of good power generation and transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

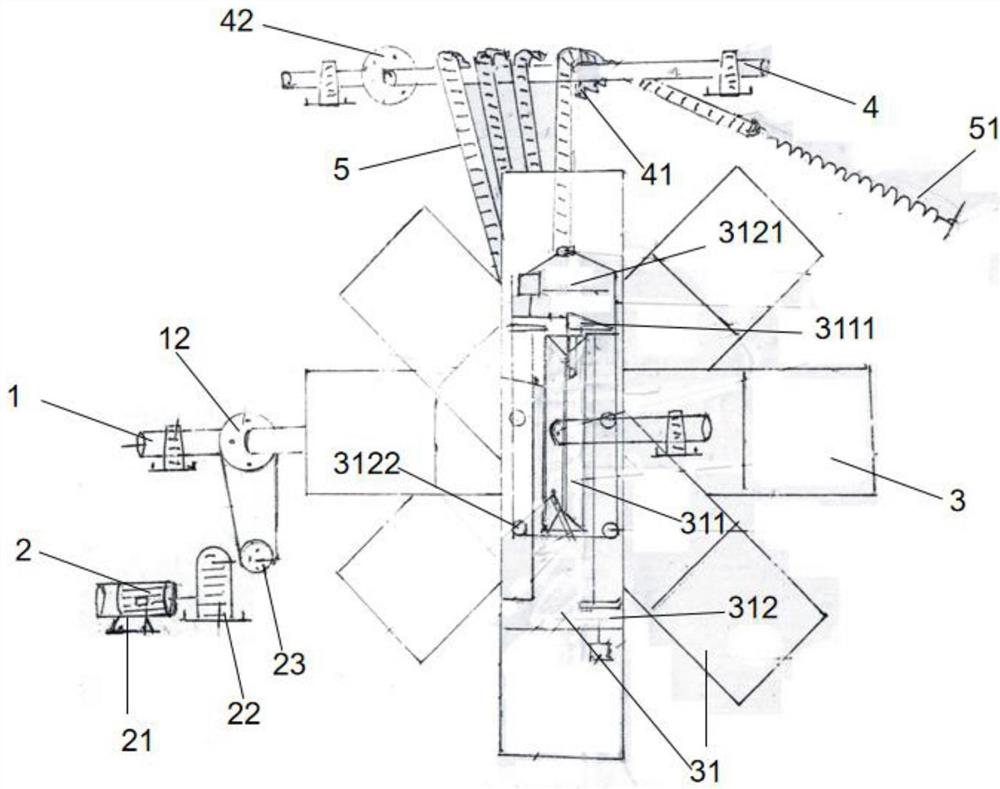

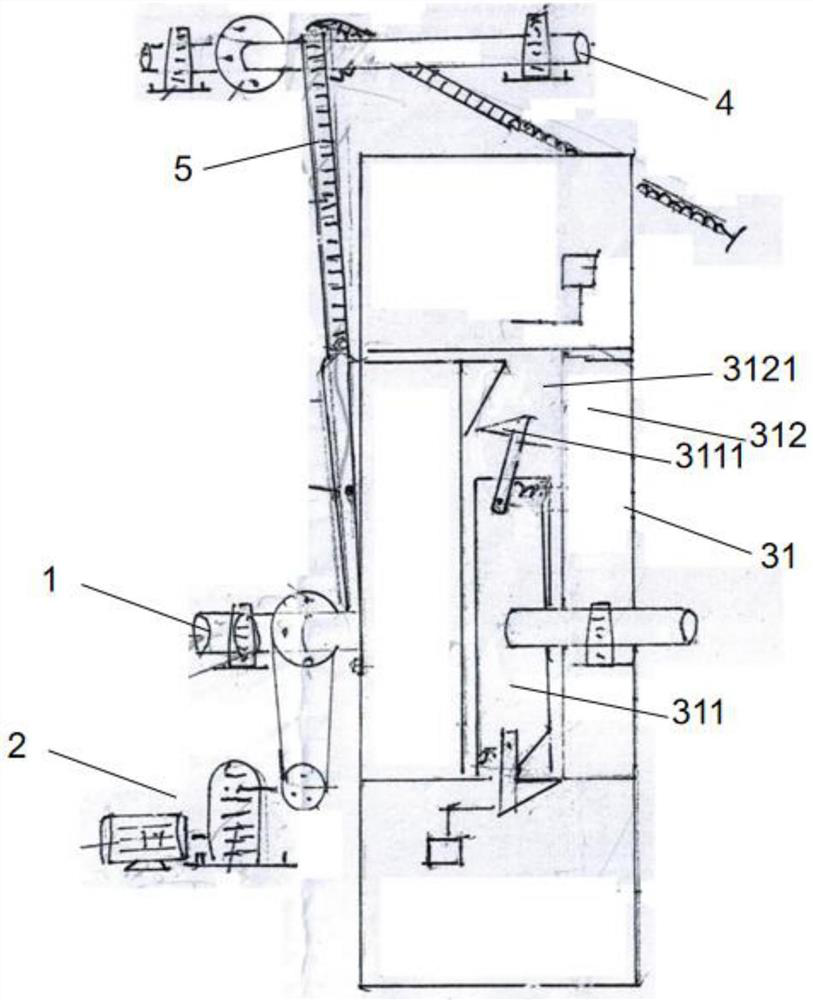

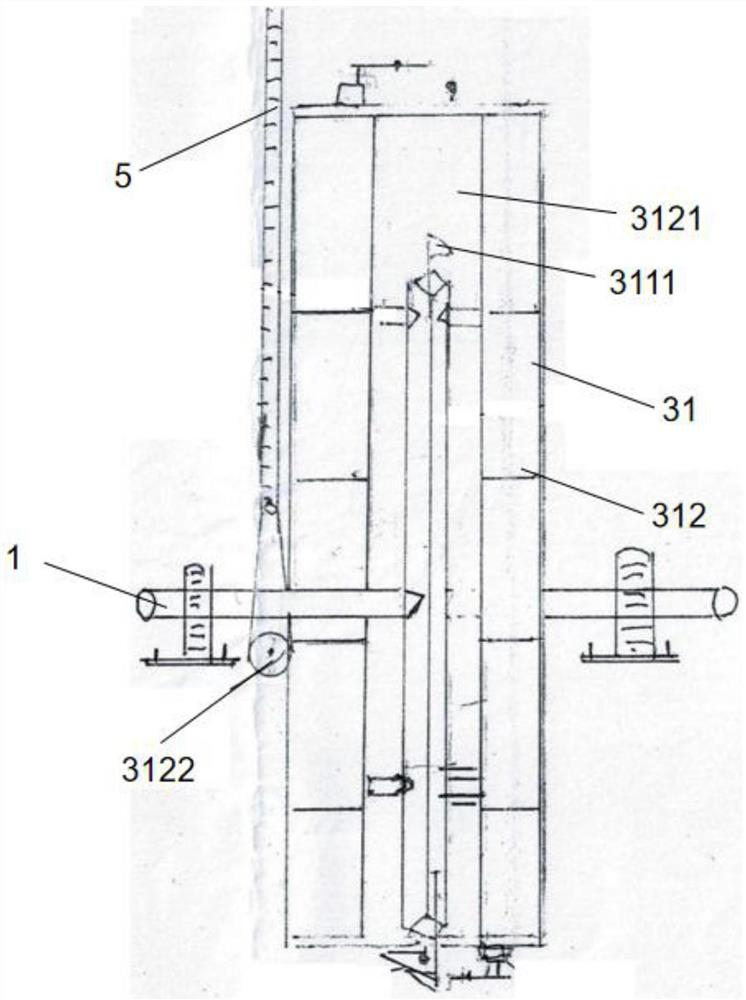

[0025] refer to Figure 1-Figure 3 The shown gravity sliding power machine includes a main shaft 1, a driving device 2, a sliding frame group 3 and a pulling shaft 4. The driving device 2 drives the main shaft 1 to rotate, and the sliding frame group 3 rotates with the main shaft 1, so The sliding frame group 3 drives the pulling shaft 4 to rotate, and the pulling shaft 4 is arranged above the sliding frame group 3 ; the sliding frame group 3 includes a plurality of sliding frames 31 that rotate coaxially with the main shaft 1 . , an inclination angle is set between each two of the sliding frames 31, and the transmission ratio of the main shaft 1 and the sliding frame group 3 is twice the number of the sliding frames 31;

[0026] The sliding frame 31 includes an outer frame 312 and an inner sliding block 311 connected to the main shaft 1 , the main shaft 1 drives the sliding frame 31 to rotate through the inner sliding block 311 , and the outer frame 312 can be opposite to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com