Industrial damping energy-saving fan

A fan and industrial technology, applied in the field of industrial shock-absorbing and energy-saving fans, can solve the problems of high motor energy consumption, poor seismic performance of the first fan blade, and poor seismic performance of industrial fans.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

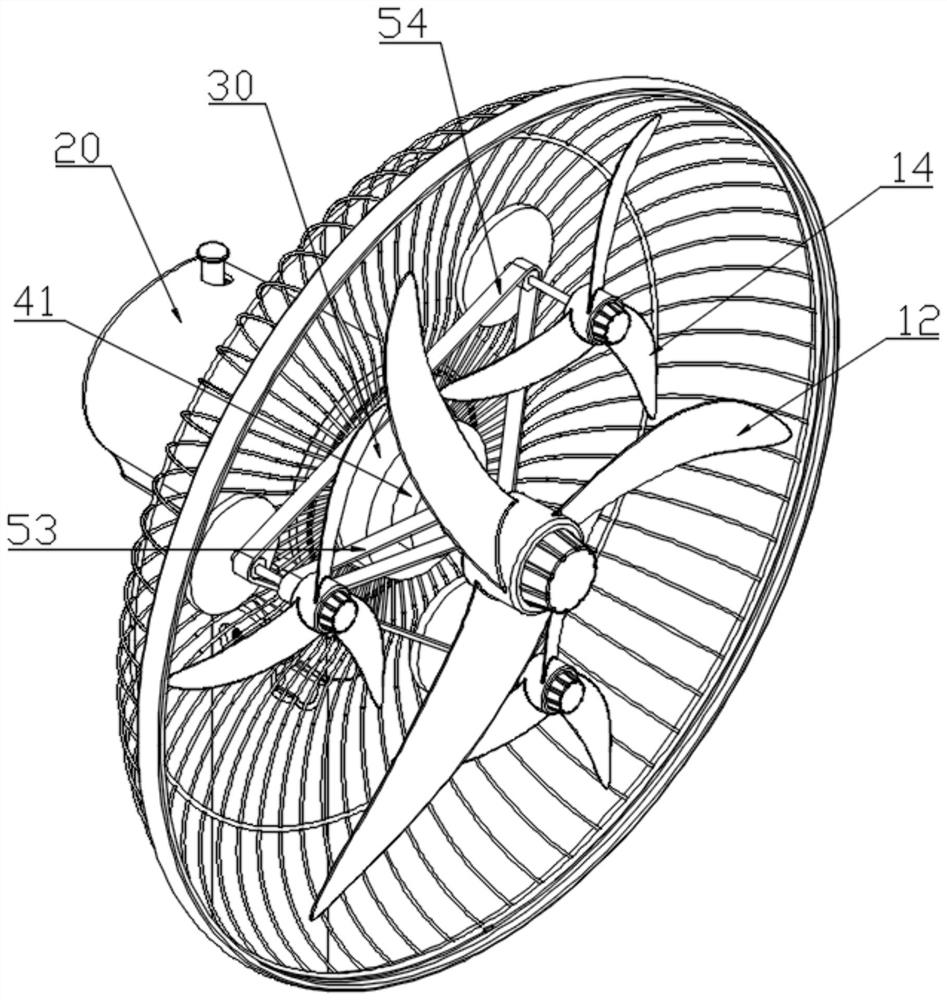

[0040] see Figure 1 to Figure 7 , An industrial shock-absorbing and energy-saving fan of this embodiment includes a fan body 10, a chassis 11, a motor 20, a first fan blade 12, a dual-mass flywheel device 30, a mounting sleeve 41, two arc-shaped fixing plates 42, and bearings 43 And two damping springs 44, three second blades 14, belt assembly ratchet pawl assembly;

[0041] Specifically, the fan body 10 is arranged on the chassis 11; the bottom of the chassis 11 is provided with a shock pad 111; the motor 20 is arranged in the fan body 10; the first fan blade 12 is arranged on the Inside the fan body 10, the first fan blade 12 is coaxially provided with a shaft 13;

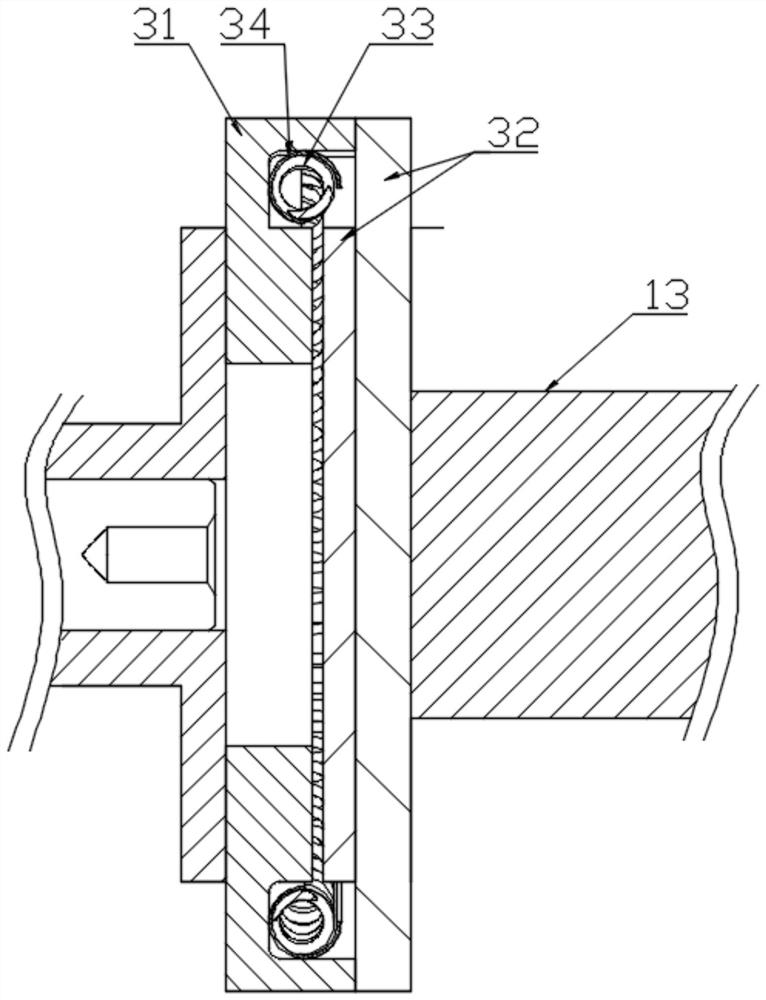

[0042] Specifically, the dual-mass flywheel device 30 is disposed in the fan body 10 , and the input and output ends of the dual-mass flywheel device 30 are respectively coaxially connected to the output shaft of the motor 20 and the shaft 13 of the first fan blade 12 .

[0043] In this preferred embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com