Hydraulic system and method for composite action control of loading machine

A compound action, hydraulic system technology, applied in mechanical equipment, earth movers/shovels, fluid pressure actuating devices, etc. Improve work productivity and operational continuity, with low engine power and strong operational controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

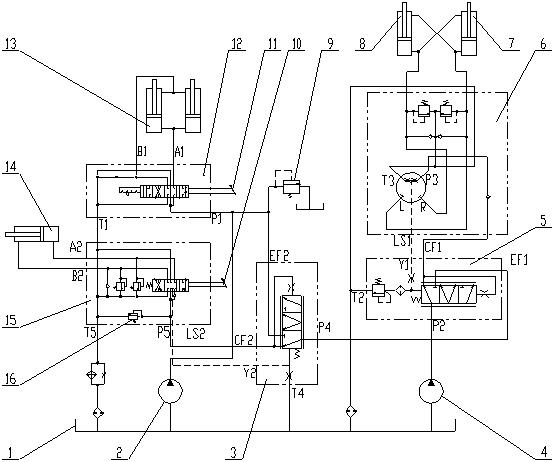

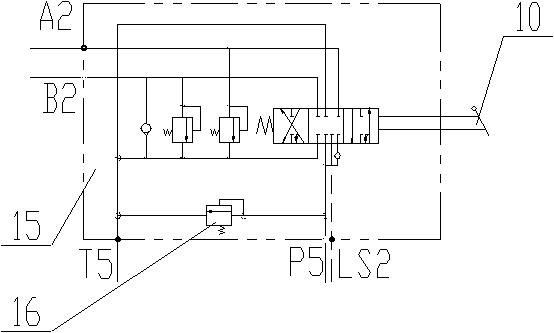

[0040] combine figure 1 and figure 2 As shown, a loader compound action control hydraulic system,

[0041] The oil suction port of the first hydraulic pump 2 is connected to the hydraulic oil tank 1 through a pipeline, and the oil outlet of the first hydraulic pump 2 is connected to the oil inlet P1 of the first control valve 12. The first joystick 11 can control the first control valve. 12 spool action. The A1 port of the first control valve 12 is connected to the rodless cavity of the boom cylinder 13, the B1 port of the first control valve 12 is connected to the rod cavity of the boom cylinder 13, and the T1 port of the first control valve 12 is connected to the hydraulic tank 1 connected.

[0042] The oil suction port of the second hydraulic pump 4 is connected to the hydraulic oil tank 1 through a pipeline, and the oil outlet port of the second hydraulic pump 4 is connected to the oil inlet port P2 of the third control valve 5 . The oil outlet EF1 of the third contro...

Embodiment 2

[0056] On the basis of the above-mentioned first embodiment, a method for controlling a composite action of a loader includes the following steps:

[0057] When steering and boom lift operations are performed at the same time;

[0058] Push the first joystick 11 to control the first control valve 12, so that the spool of the first control valve 12 is moved to the right or left to change direction. At this time, the first hydraulic pump 2 directly supplies oil to the rodless cavity of the boom cylinder 13 Or there is a rod cavity to realize the lifting or lowering of the boom;

[0059] At the same time, the steering wheel controls the rotation and reversal of the internal valve core of the steering gear 6. When the internal valve core of the steering gear 6 rotates, a load signal will be output from the feedback oil port LS1 of the steering gear 6 into the control port Y1 of the third control valve 5 to push the third The spool of the control valve 5 moves to the right, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com