Layer-based separation method of automatic monitoring and counting system for stored tobacco leaf pests

An automatic monitoring and tobacco leaf technology, which is applied in the field of tobacco leaf pest number and gas composition detection, can solve problems such as hidden safety hazards, and achieve the effect of reducing corrosion and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

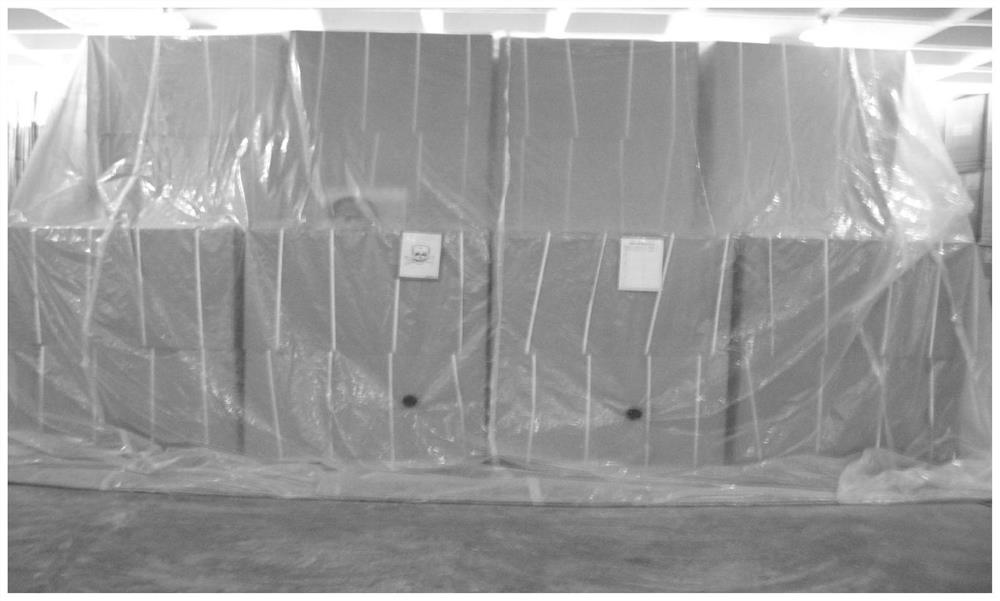

[0074] According to the specifications and dimensions of the stacked tobacco leaves, a plastic sealing tent that can completely cover the stack of sealed tobacco leaves is produced and a plastic tent sealing space 2 (space sealed by the plastic tent) is constructed, and the plastic tent is strictly checked for leaks. Make the sealed space of the tent meet the strict air tightness standard (according to the industry standard of the food system, the secondary air tightness can be the standard), so that it has the conditions for putting phosphine in airtight fumigation or carrying out mechanical nitrogen filling for insect control. There is a separation layer between the sealed space formed by the above-mentioned plastic tent sealed tobacco stack and the external environment---the wall layer of the plastic sealed tent.

[0075] Use tobacco beetle sex pheromone pest traps (ie pest traps) produced by Japan's Fuji Company or Wuhan Dongchang Storage Technology Co., Ltd. to monitor and...

Embodiment 2

[0094] It is basically the same as Example 1, the difference is that: in order to ensure that the image acquisition device and the pest trap are not disturbed by the pollution of dust in the environment, the trap and the image acquisition device are jointly installed in a protective box (equipment integrated box) 6 Among them, the protection box 6 is made of metal or plastic material, and under the premise that the flat arrangement of the insect-catching adhesive panel 4 of the pest trap and the image acquisition device 5 can be set at 5-100 cm directly opposite the insect-catching adhesive panel, The protective box can be made into various suitable shapes, and a movable cover plate and a number of movable covers that can open and replace the insect-catching adhesive panel 4 (and the tobacco pest sex pheromone lure core adhered on it) and the image acquisition device are arranged on the protective box. Openings for pests to enter and exit; the protective box 6 can be hung on th...

Embodiment 3

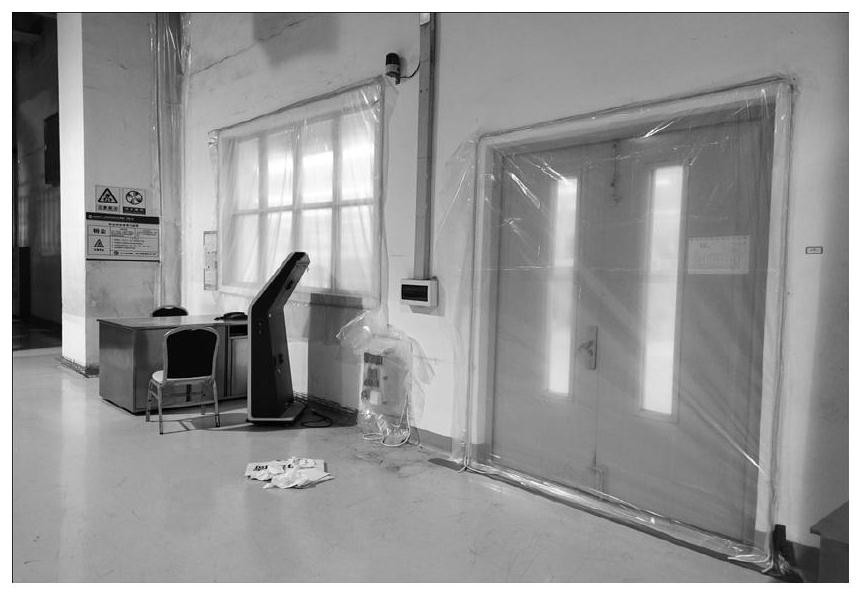

[0097] Basically the same as Embodiment 1, 2, the difference is: the host 8 of the automatic monitoring and counting system of stored tobacco leaf pests outside the wall layer 1 of the plastic-sealed tent and the wall layer 1 of the plastic-sealed tent keep not less than 30 cm. To ensure that the host 8 is outside the harmful gas accumulation layer 9 that may exist around the plastic sealed tent and formed around the gas leakage point, forming a kind of "insect trapping glue panel 4 + image acquisition device 5" in the plastic sealed tent The inside of the wall layer 1 of the system and the host 8 of the system are in a layer-by-layer relationship of "the wall layer 1 of the plastic sealing tent + the accumulation layer 9 of harmful gas escaping from the plastic sealing tent" to ensure that the host of the system is not affected by the plastic. Corrosive fouling of carbon dioxide or phosphine gas escaping from the tent seal space 2 ( Image 6 ), the host 8 of the system is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com