Flexible circuit board bonding pad windowing manufacturing process using flexible ink

A flexible circuit board and manufacturing process technology, applied in the direction of printed circuit manufacturing, assembling printed circuits with electrical components, printed circuits, etc. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Next, combine Figure 1-3 A specific embodiment of the present invention is described in detail.

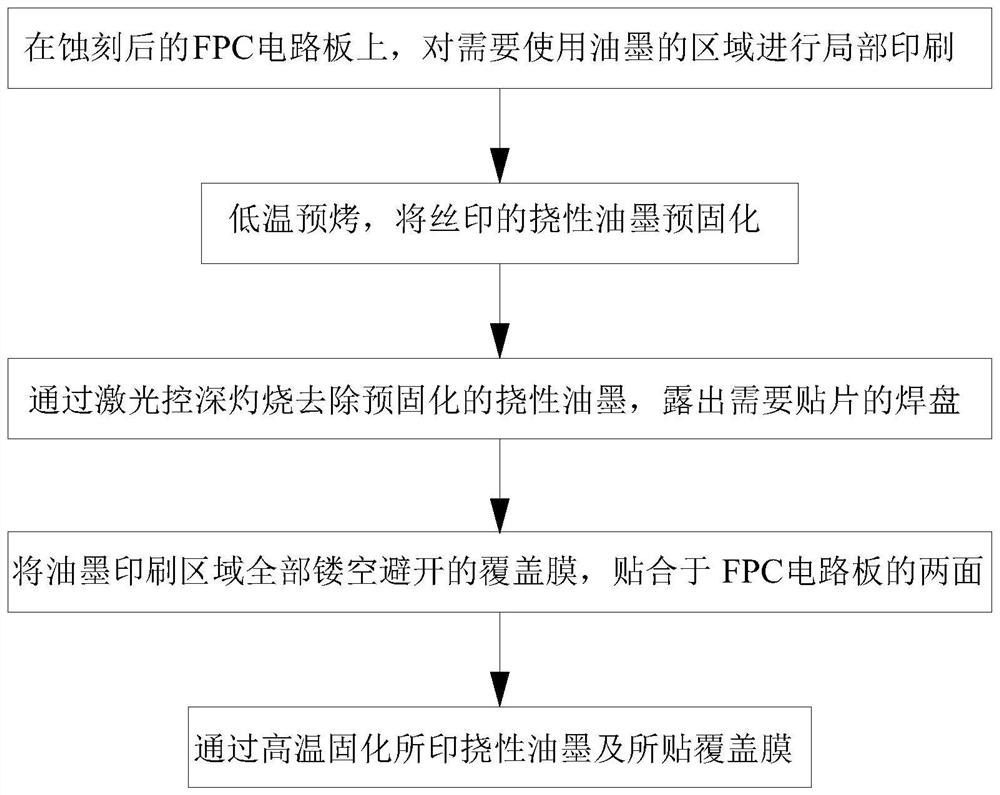

[0038] Reference attached figure 1 , a flexible circuit board pad window manufacturing process using flexible ink, comprising the following steps:

[0039] Step 1, print solder mask, and perform partial printing on the area where ink needs to be used on the etched FPC circuit board;

[0040] Step 2, curing, pre-curing the silk-screened flexible ink by pre-baking at a low temperature;

[0041] Step 3, laser control depth, remove the pre-cured flexible ink by laser control depth burning, and expose the pads that need to be patched;

[0042] Step 4, paste the cover film, and attach the cover film that is avoided by hollowing out all the ink printing area, and attach it to both sides of the FPC circuit board;

[0043] Step 5, curing, the printed flexible ink and the attached cover film are cured by high temperature.

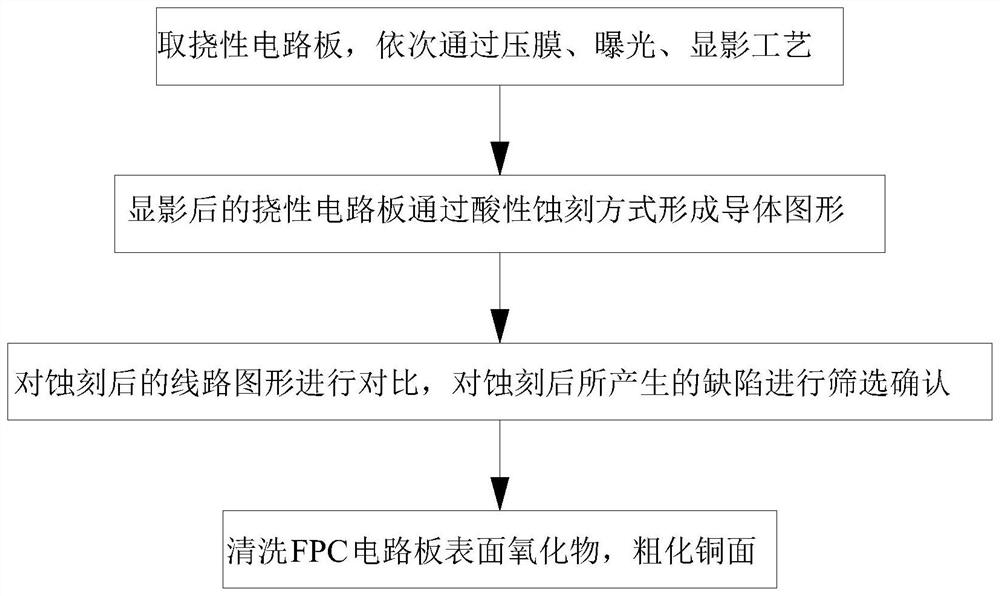

[0044] Reference attached figure 2 , before step 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com