Cloth bag filter with self-cleaning function

A cloth bag filter and self-cleaning technology, which is applied in the direction of gravity filter, fixed filter element filter, filter circuit, etc., can solve the problems that the filtering effect of the filter and the life of the filter affect the processing operation, etc., and achieve light weight, prolong life, Guarantee the effect of filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

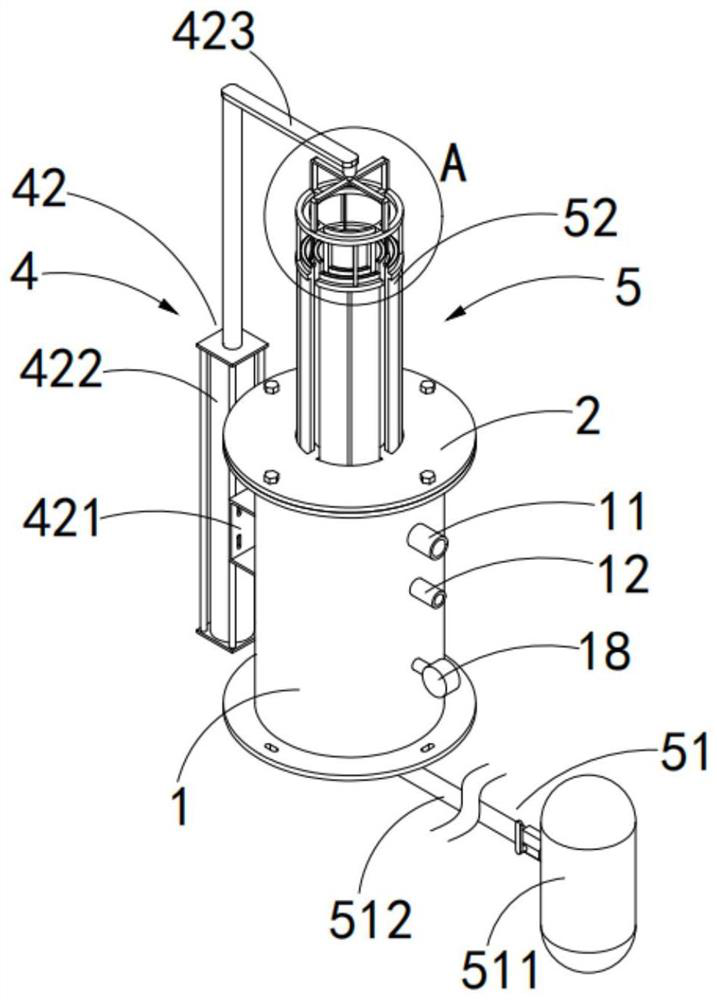

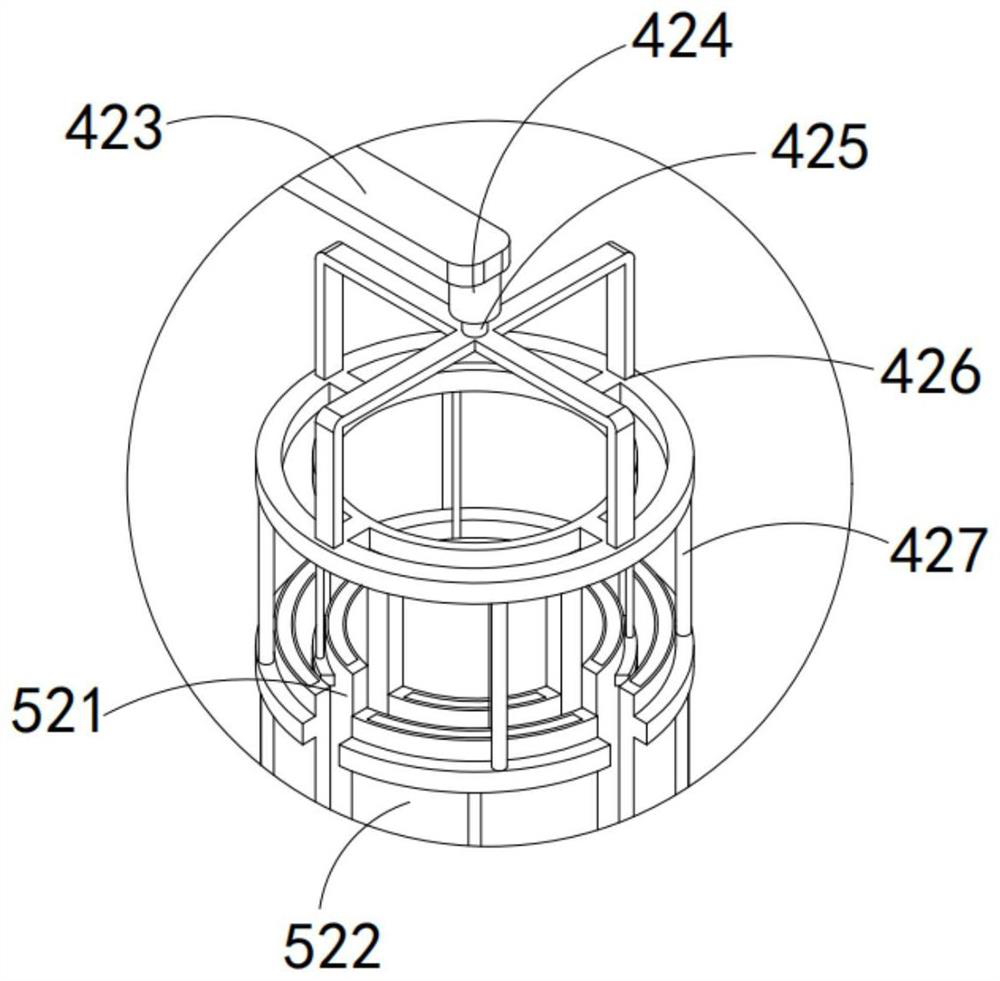

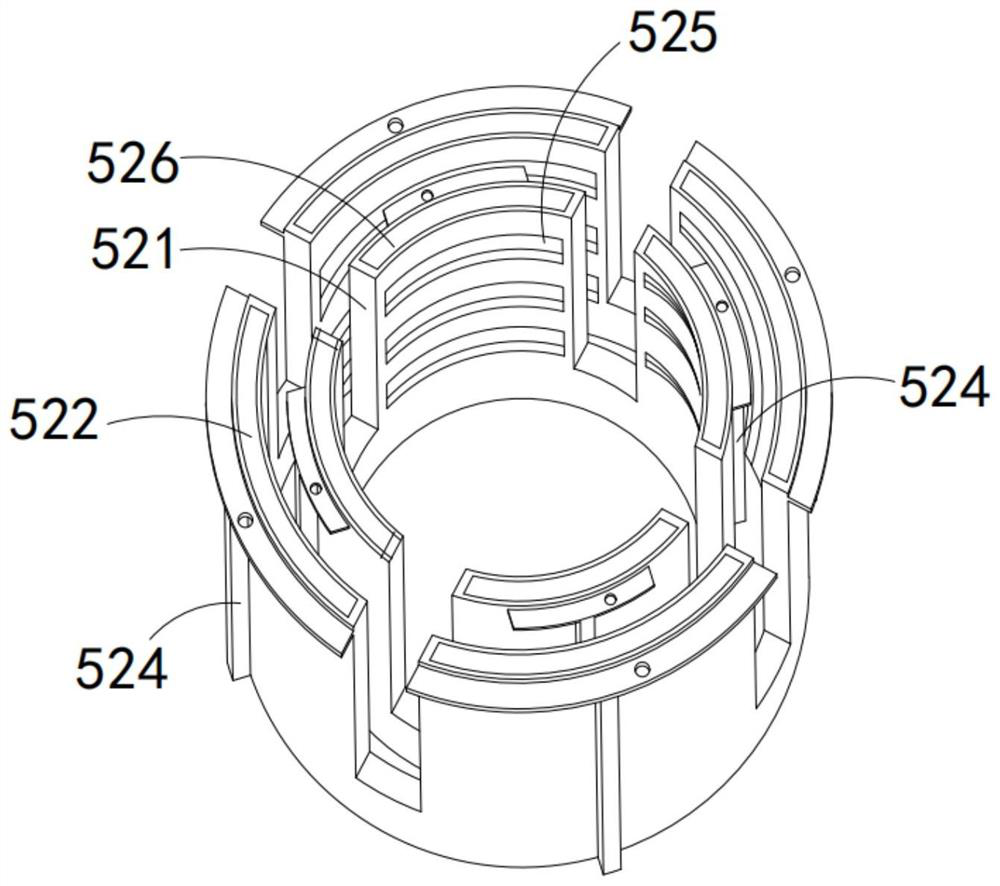

[0030] like Figure 1 to Figure 8 As shown, a bag filter with self-cleaning function includes a tank body 1, a flange cover 2 arranged on the top of the tank body 1, and a filter mechanism 3 arranged inside the tank body 1. The tank body 1 is provided with a transmission mechanism 4. A cleaning mechanism 5 is provided on one side of the filter mechanism 3. The filter mechanism 3 includes a filter inner core 31, an inner core sleeve 32 and a cloth bag 33 that are sleeved in sequence. The transmission mechanism 4 includes a rotating assembly 41 and a lifting assembly 42. The cleaning mechanism 5 includes The air blowing assembly 51 and the collecting assembly 52. The collecting assembly 52 includes a baffle a521 and a baffle b522. The baffle a521 and b522 are both provided with a collection cavity 523. The baffle a521 and b522 are driven by the lifting assembly 42. The outer rings of the filter inner core 31 and the inner core sleeve 32 are respectively blocked and rotated und...

Embodiment 2

[0040] like Figure 7 As shown in the figure, the same or corresponding parts as in the first embodiment are marked with the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the differences from the first embodiment are described below; the difference between the second embodiment and the first embodiment The point is: the air inlet 16 is provided with a one-way valve 16; by setting the one-way valve 16, the air inlet 16 can only allow gas to enter in one direction, so as to prevent impurities in the tank 1 from falling into the air inlet pipe a513 and the air inlet pipe B514 and air intake pipe c515 affect the work and safety of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com