Stable Venturi device for semi-dry desulfurization and evaluation model

A semi-dry desulfurization and Venturi technology, applied in the field of semi-dry desulfurization, can solve the problems of high airflow stability requirements, semi-dry applicability limitations, and hidden dangers of unit operation, so as to improve reaction efficiency and operational stability , The market application prospect is broad, the effect of operation stability guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

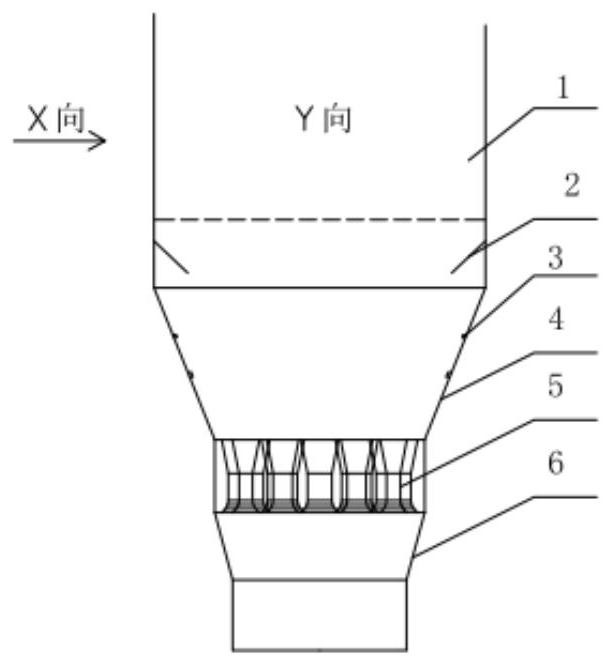

[0045] The present embodiment provides a stable Venturi device for semi-dry desulfurization, the details of which are as follows:

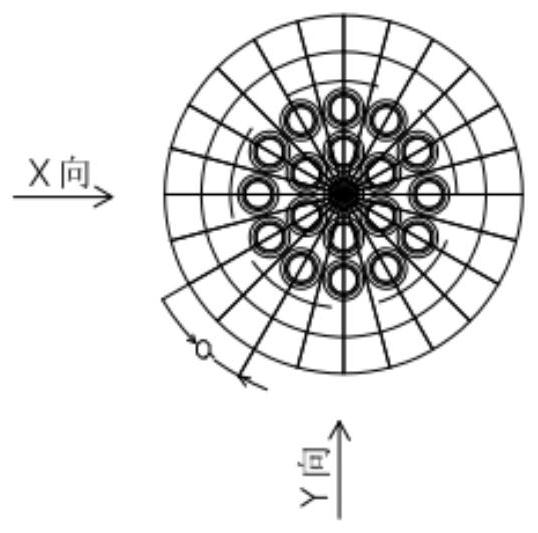

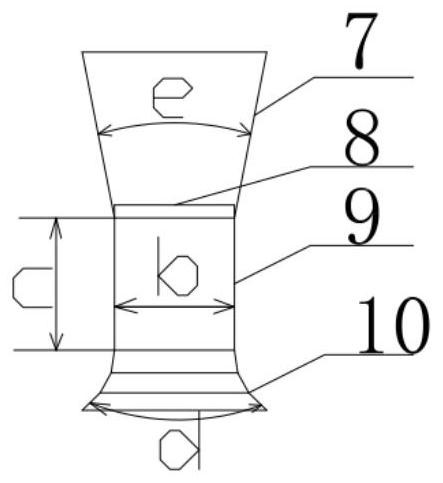

[0046] A three-layer 19-hole stable Venturi device is used, in which, from the center to the outside, the first layer is provided with 1 hole, the second layer is provided with 6 holes, the third layer is provided with 12 holes, and the angle of the outermost Venturi tube is 30 °, a steady flow sleeve is set in the tapered section inside the Venturi tube, the Venturi tube: the throat length c of the throat pipe 9 is 0.8m, and the throat diameter b is 0.72m (the throat length c is 1.11 times the throat diameter b, which meets the design requirements. requirements), the diffusion angle e of the diffusion section 7 is 22.1°, the contraction angle d of the constriction section 10 is 56°, the height of the steady flow sleeve 8 is 0.1m, the inner diameter is 0.72m, the height of the 19-hole Venturi tube is 2.1m, and the steady flow sleeve The cylinder h...

Embodiment 2

[0051] The present embodiment provides a stable Venturi device for semi-dry desulfurization, the details of which are as follows:

[0052] Four layers of 43-hole stabilized Venturi are used. From the center to the outside, the first layer is provided with 1 hole, the second layer is provided with 6 holes, the third layer is provided with 12 holes, the fourth layer is provided with 24 holes, and the outermost layer of Venturi is provided with 1 hole. The included angle of the tube is 15°, and a steady flow sleeve is set in the tapered section inside the Venturi tube. The size of the Venturi tube: the throat length c is 0.55m, and the throat diameter is 0.5m (the throat length c is 1.11 times the throat diameter b). , to meet the design requirements), the diffusion angle e of the diffuser section is 22°, the contraction angle d of the contraction section is 56°, the steady flow sleeve is 0.1m, the inner diameter is 0.5m, and the total height of the 43-hole Venturi device is 1.5m....

Embodiment 3

[0057] The present embodiment provides a stable Venturi device for semi-dry desulfurization, the details of which are as follows:

[0058] Two three-layer 19-hole stable Venturi desulfurization towers in the series-parallel structure of Example 1 were adopted, and the height of the Venturi tube was 2.1 m.

[0059] The stable venturi device is welded with the inlet flue and the two desulfurization towers respectively. The original flue gas flue of each channel is connected to the two desulfurization towers, and the clean flue gas of the two towers is connected to the two desulfurization towers. The recirculated clean flue gas first enters the desulfurization tower through the stable venturi device, and the flue is connected by the baffle door switch to ensure the flow of the gas flow to realize the switching of the two towers and the series-parallel operation.

[0060] When the full load of the flue gas flow is 600MW, the pressure of the tower body of the desulfurization tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com