Immersed ultrafiltration membrane chemical cleaning liquid medicine recycling method

A chemical cleaning and submerged membrane technology, which is applied in chemical instruments and methods, membrane technology, semipermeable membrane separation, etc., can solve the high anti-corrosion requirements of the inner wall and pipeline of the membrane tank, the large volume of the submerged ultrafiltration membrane tank, and the reduction of the system Anti-corrosion life and other issues, to achieve the effect of improving the utilization rate of chemicals, saving the cost of drug consumption, and prolonging the overall life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

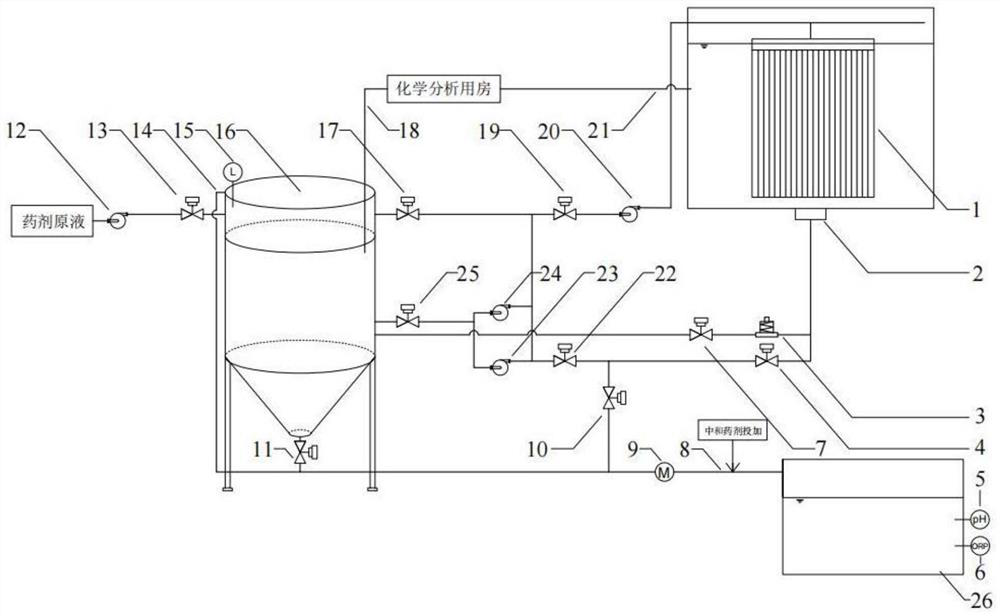

[0042] Example: figure 1 It is mainly composed of submerged ultrafiltration membrane tank, chemical cleaning water tank, neutralization tank and supporting auxiliary systems (chemical analysis room, supporting pumps, valves, pipes, instruments, etc.). figure 1 The liquid level of the immersed ultrafiltration membrane during on-line chemical cleaning is shown. The liquid in the membrane tank is chemical cleaning liquid, generally acid cleaning agent, alkali cleaning agent or chlorine cleaning agent (sodium hypochlorite). Only one membrane tank and cleaning water tank are shown in the figure to illustrate the embodiment. When the actual ultrafiltration membrane system is running, many groups of membrane tanks and cleaning water tanks share some valves and pipes, which do not affect the operation of this embodiment. No longer.

[0043] The submerged ultrafiltration membrane module 1 is set in the submerged membrane tank as the core unit of water production (in this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com