Ultrahigh-voltage-resistant insulating resin suitable for vacuum suction and injection molding and preparation method thereof

A technology of vacuum suction and insulating resin, applied in the field of insulating resin, can solve the problems of high viscosity and inapplicability, and achieve the effects of good mechanical properties, improved comprehensive performance and good electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

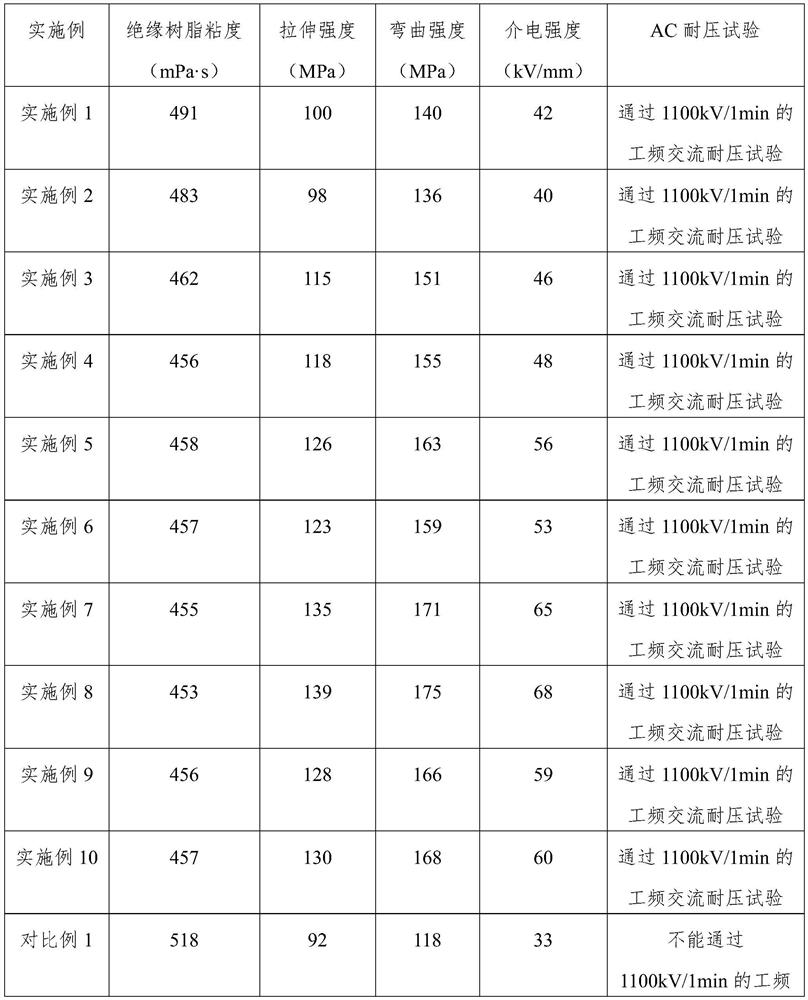

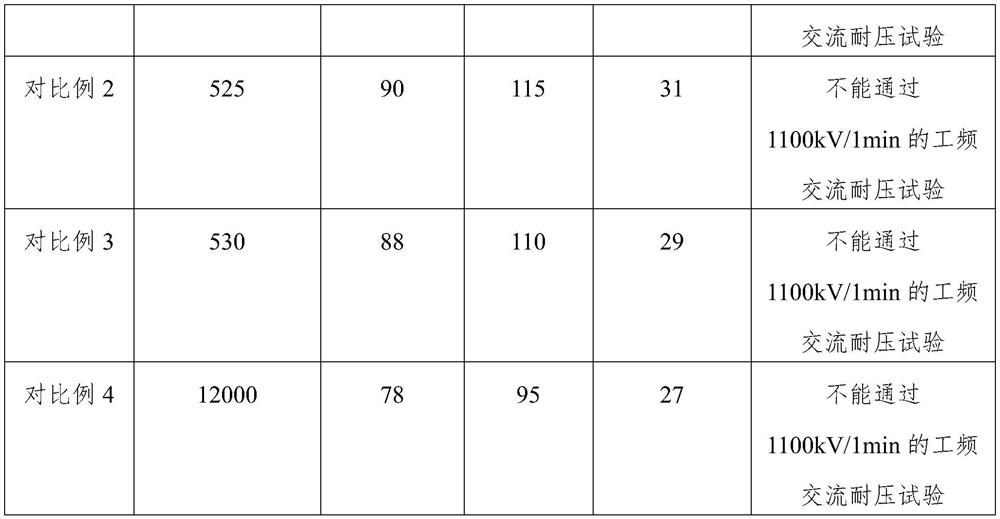

Examples

preparation example Construction

[0027] The present invention provides, in a first aspect, a preparation method of an ultra-high voltage resistant insulating resin suitable for vacuum injection molding, the preparation method comprising the following steps:

[0028] (1) According to the mass ratio of the matrix resin and the toughening agent is (2-15):1 (for example, 2:1, 3:1, 4:1, 5:1, 6:1, 7:1, 8:1 , 9:1, 10:1, 11:1, 12:1, 13:1, 14:1 or 15:1), and then under an inert gas (such as N 2 ) under the protection of 60-100°C (eg 60°C, 65°C, 70°C, 75°C, 80°C, 85°C, 90°C, 95°C or 100°C) under stirring for 1-3h (eg 1, 1.5, 2, 2.5 or 3h) to obtain a toughened matrix resin; in some specific embodiments, after mixing the matrix resin and the toughening agent according to the mass ratio, start stirring, the stirring speed is 200r / min, and at the same time, feed N 2 , heated to 80°C, and stirred for 2 hours; after stirring, a toughened matrix resin was obtained.

[0029] (2) According to the mass ratio of the toughening...

Embodiment 1

[0057] Step 1: Preparation of toughened matrix resin

[0058] After mixing 40 parts of bisphenol F type epoxy resin 830S with 5 parts of liquid polysulfide rubber (JLY-121 liquid polysulfide rubber), start stirring, and the stirring speed is 200r / min; at the same time, feed N 2 , heated to 80°C, and stirred for 2 hours; after stirring, a toughened matrix resin was obtained.

[0059] Step 2: Modification of toughened matrix resin

[0060] Add the toughened base resin obtained in step 1 and 5 parts of modifier (triethylamine) into a stirring vessel (the mass ratio of toughened base resin to modifier is 9:1), and in an oil bath of 80 Stir at ℃ for 4 hours to obtain the first modified and toughened matrix resin.

[0061] Step 3: Preparation of the second modified and toughened matrix resin

[0062] 10 parts of silane (ethyl orthosilicate) and the first modified and toughened base resin obtained above were added to the container (the mass ratio of the first modified and toughene...

Embodiment 2

[0066] Step 1: Preparation of toughened matrix resin

[0067] After mixing 70 parts of bisphenol F type epoxy resin 830S with 15 parts of liquid polysulfide rubber (JLY-121 liquid polysulfide rubber), start stirring, and the stirring speed is 200r / min; 2 , heated to 80°C, and stirred for 2 hours; after stirring, a toughened matrix resin was obtained.

[0068]Step 2: Modification of toughened matrix resin

[0069] Add the toughened base resin obtained in step 1 and 15 parts of modifier (triethylamine) into a stirring vessel (the mass ratio of toughened base resin to modifier is 5.7:1), and in an oil bath of 80 Stir at ℃ for 4 hours to obtain the first modified and toughened matrix resin.

[0070] Step 3: Preparation of the second modified and toughened matrix resin

[0071] Add 30 parts of silane (ethyl orthosilicate) and the first modified and toughened base resin obtained above into the container (the mass ratio of the first modified and toughened base resin to silane is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com