Packaging substrate deformation measurement equipment and method thereof

A technology for packaging substrates and measuring equipment, applied in measuring devices, optical devices, instruments, etc., can solve the problems of large measurement errors, error accumulation, unfriendly interface, etc., and achieve the effect of accurate measurement and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

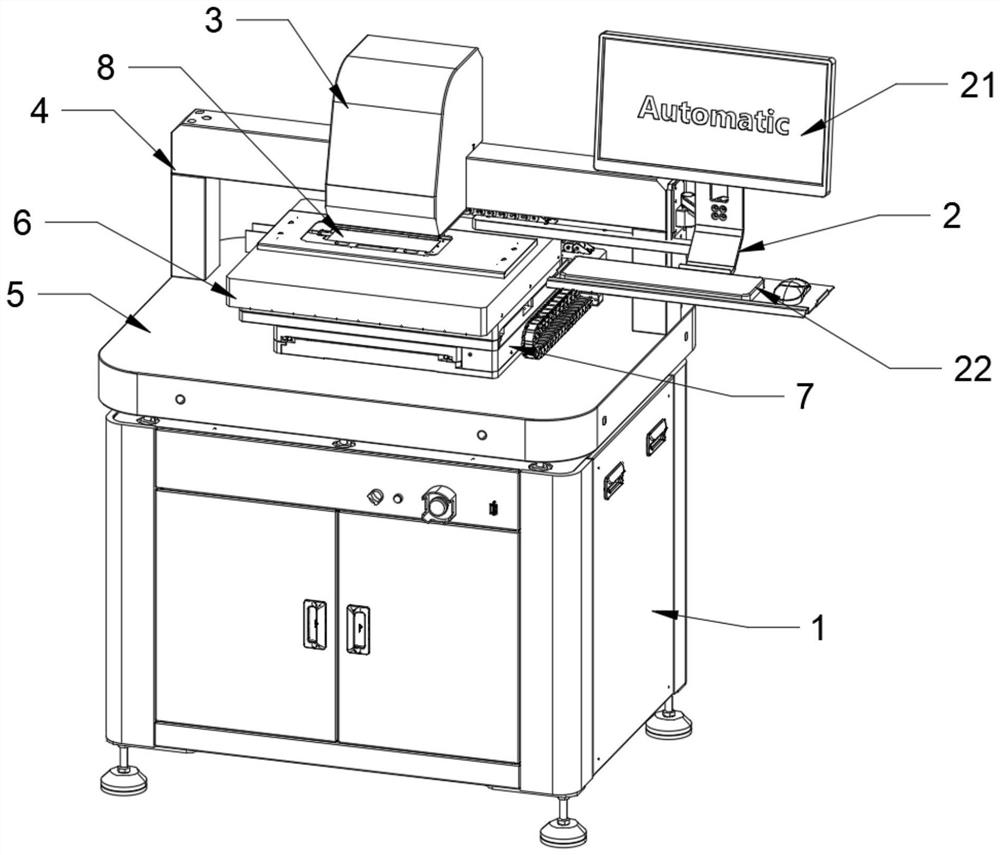

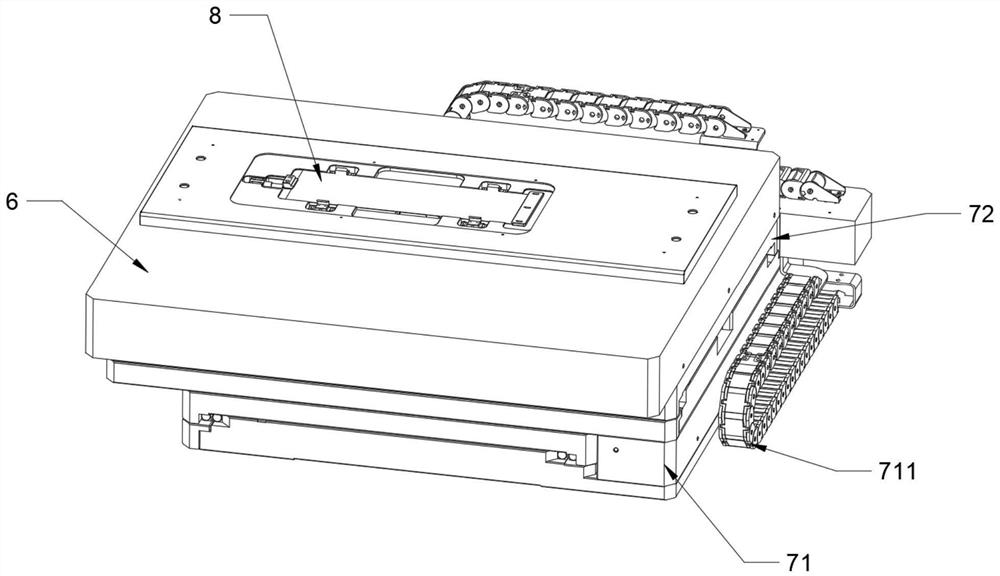

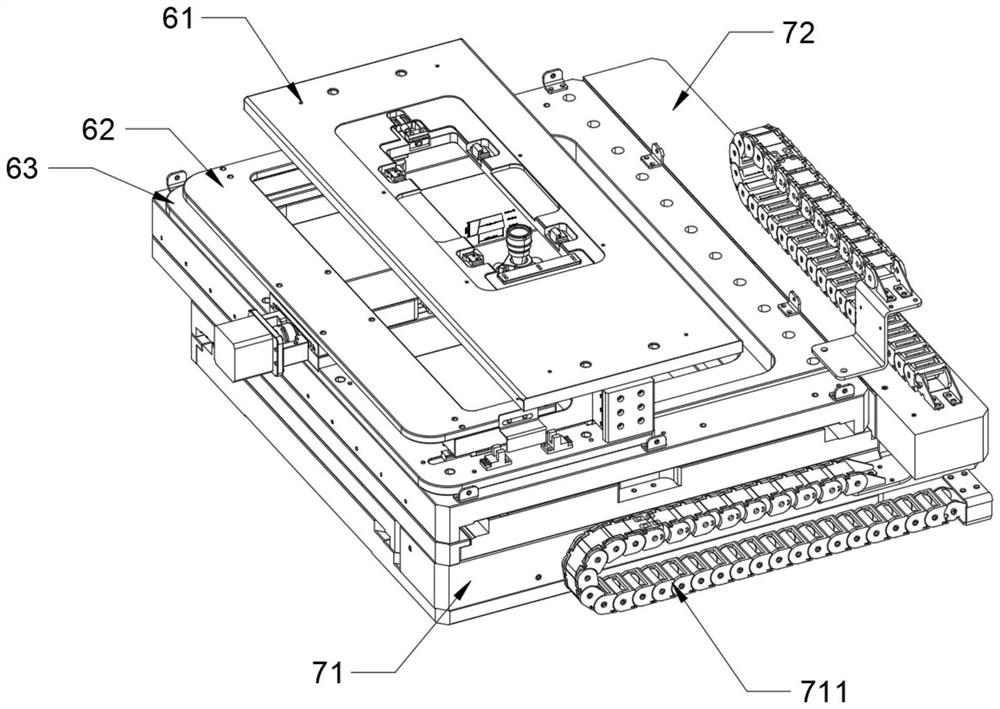

[0039] Example one, by Figure 1-4 and Figure 7 Provided, a package substrate deformation measurement device, including a body 1, a marble platform 5 is installed on the upper end of the body 1, and a precision hollow motion platform 7 is installed on the upper end of the marble platform 5, and the upper end of the precision hollow motion platform 7 is driven and connected with a measurement clamping module 6, and the sample tray 8 is clamped at the upper end of the measurement clamping module 6, the gantry frame 4 is installed on the rear side of the upper end of the marble platform 5, and the upper middle part of the gantry frame 4 is located above the measurement clamping module 6. A measurement module 3 is installed, The lower end of the measurement module 3 is equipped with a wired laser sensor, an upper facing laser sensor, and a vision sensor, and a support frame 2 is installed at the side end of the gantry frame 4, and a display screen 21 and a control keyboard module 2...

Embodiment 2

[0050] Embodiment 2, on the basis of Embodiment 1, a method for measuring deformation of a package substrate, which includes the following steps:

[0051] S1. First power on the device and the PC, and then control the PC to start the control software;

[0052] S2. When the software starts, it will first perform a self-check of the device. If the self-check fails, an error prompt will pop up to check. The software can be started only after the self-check is passed normally;

[0053] S3. Place the sample on the tray before testing, and select whether to use the holding plate 613, multiple side clamping cylinders 615 and push clamping cylinders 614 to clamp and fix the sample tray 8 according to the specific situation. ;

[0054] S4. Select the measurement content in the software on the PC side, set the test parameters, manually align with the real-time image fed back by the visual sensor, and then click the measurement button to start the measurement;

[0055] S5. During the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com