Epoxide preparation device and epoxide preparation method

A technology for epoxide and preparation equipment, which is applied in chemical instruments and methods, chemical/physical processes, organic chemistry, etc., and can solve problems such as increased investment costs, large heat release, and catalyst blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

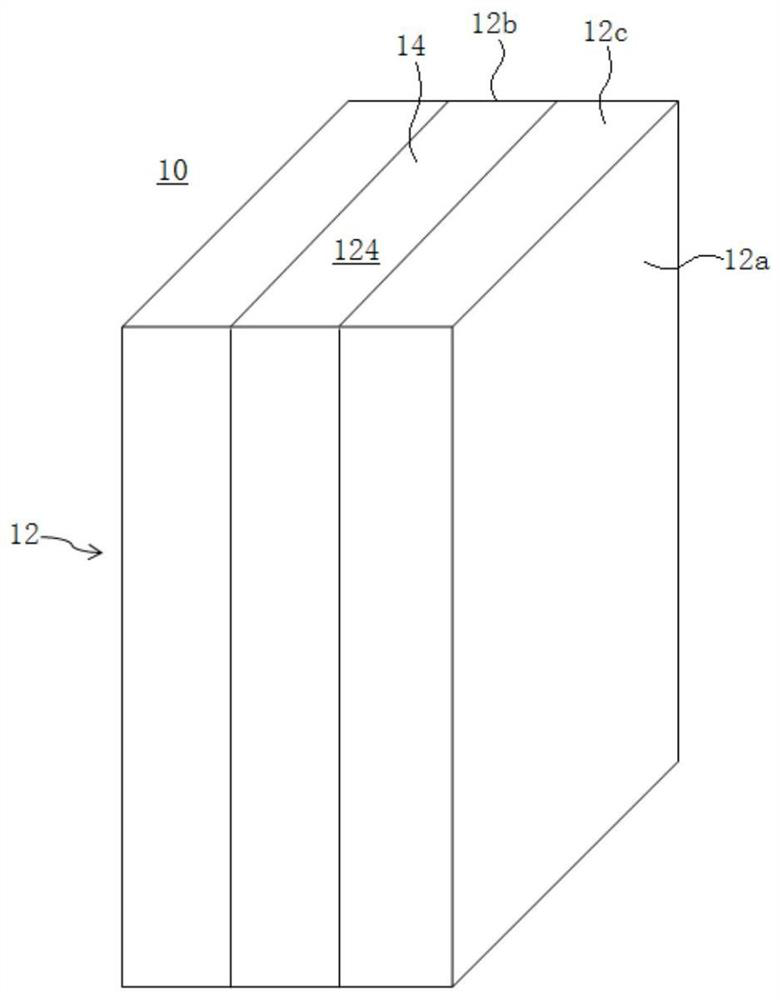

[0035] The present invention provides an epoxy preparation device. The epoxy preparation device 10 includes a main body 12. The main body 12 is in the shape of a polygonal ring. It can be understood that the main body 12 has an inner peripheral wall and an outer peripheral wall. The inner peripheral wall of the main body 12 The main body 12 includes at least one reaction wall 12a, the reaction wall 12a has a reaction chamber capable of filling the catalyst, and the outer wall surface of the reaction wall 12a facing away from the main body 12 is provided with an inlet for the feed gas to enter the reaction chamber. The material port, the inner wall surface of the reaction wall 12a facing the main body 12 is provided with a discharge port for discharging the epoxide obtained by the reaction of the raw material gas under the action of the catalyst. It can be understood that the reaction wall 12a has a certain thickness, The reaction chamber can be arranged in the reaction wall 12a...

Embodiment 1

[0061] use figure 1 The shown preparation device for epoxide prepares ethylene oxide, wherein the main body 12 is in the shape of a cuboid, and the main body 12 includes 2 reaction walls 12a and 2 connecting walls 12b, and the 2 reaction walls 12a and 2 connecting walls 12b are along the The circumferential direction of the main body 12 is alternately distributed. The outer wall surface of the reaction wall 12a is in the shape of a grid, wherein a plurality of first mesh holes are distributed in a matrix, the first mesh holes are formed as feed ports, and the total area of the plurality of first mesh holes is the total area of the outer wall surface. 40%; the inner wall surface of the reaction wall 12a is in a grid shape, wherein the plurality of second mesh holes are distributed in a matrix, the second mesh holes are formed as discharge ports, and the total area of the plurality of second mesh holes is the inner wall surface. 40% of the total area; the reaction chamber...

Embodiment 2

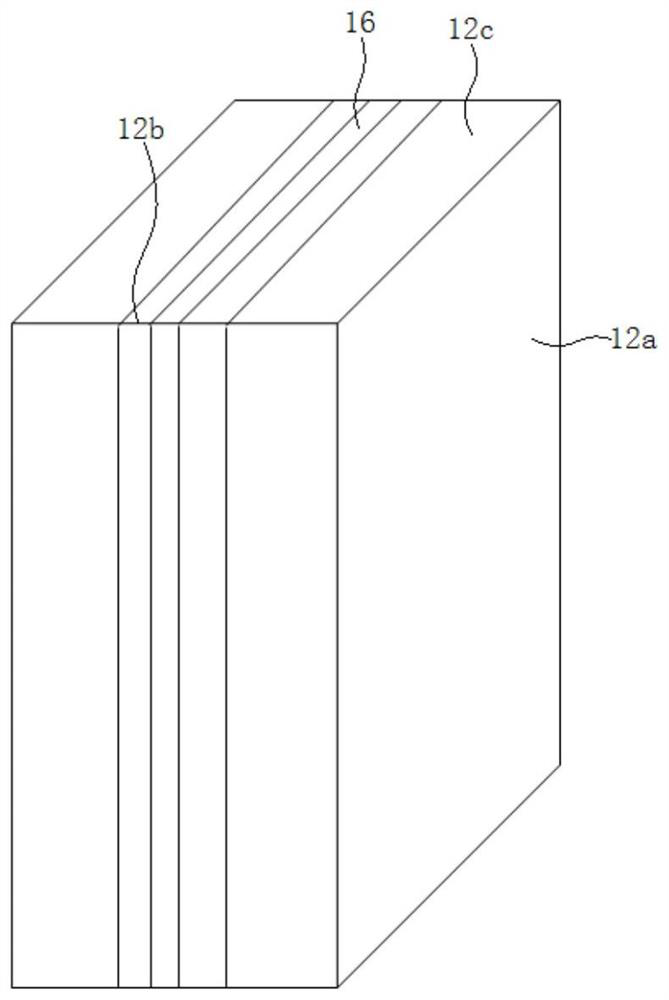

[0065] The epoxide preparation device provided by the present invention is used to prepare ethylene oxide, wherein the main body 12 is in the shape of a cuboid, and the main body 12 includes two reaction walls 12a and two connecting walls 12b, and two reaction walls 12a and two connecting walls The walls 12b are alternately distributed along the circumference of the main body 12 . The outer wall surface of the reaction wall 12a is provided with a plurality of first openings, wherein the first openings extend in a direction perpendicular to the height direction of the reaction wall 12a, the plurality of first openings are spaced along the height direction of the main body 12, and the first openings form For the feed port, the total area of the first openings is 30% of the total area of the outer wall surface; the inner wall surface of the reaction wall 12a is provided with a plurality of second openings, wherein the second openings are perpendicular to the height of the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com