High-temperature hot-pressing pump pickling device for non-metal mine

A high-temperature hot-pressing, non-metallic ore technology, used in cleaning methods and utensils, improving process efficiency, and cleaning methods using liquids, etc. The effect of speeding up leaching efficiency, improving production efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

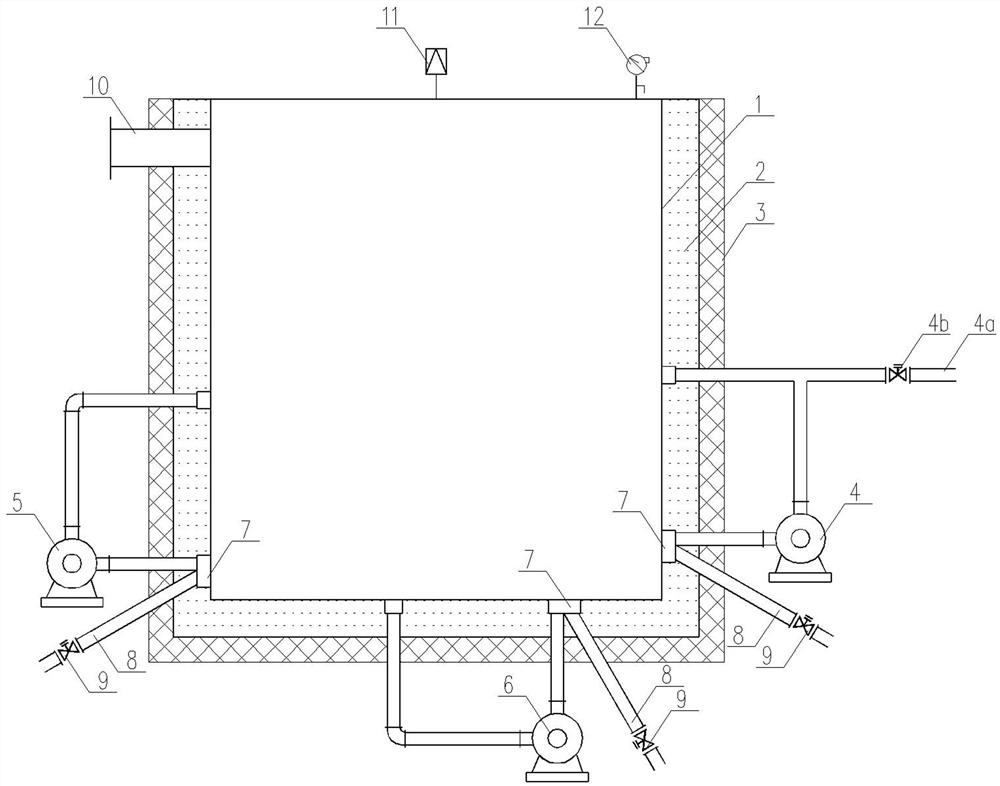

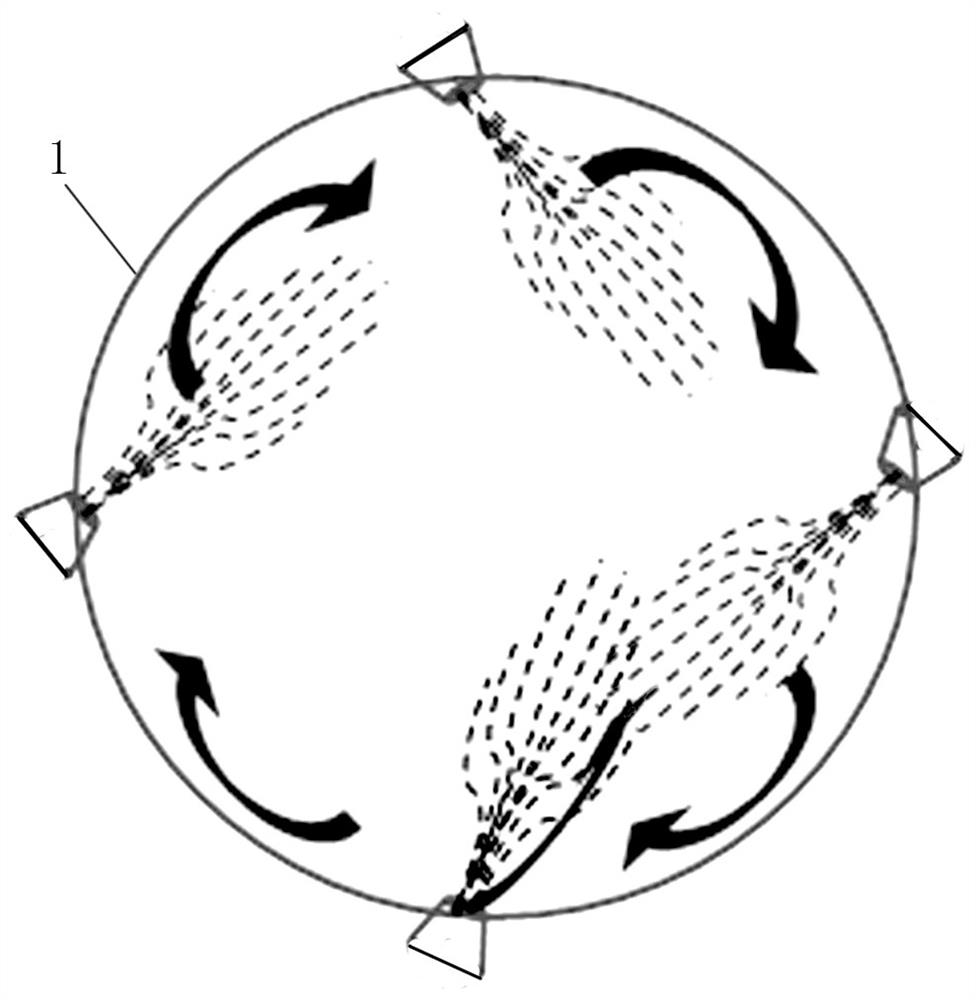

[0020] like figure 1 and 2 As shown, a high-temperature hot-pressure pump pickling device for non-metallic mines includes a tank body 1, a feed port 10 is installed on the upper part of the tank body 1, an automatic pressure relief valve 11 and a pressure gauge are installed on the top of the tank body 1 12.

[0021] A heat exchange tank 2 and a thermal insulation layer 3 are sequentially sleeved on the outside of the tank body 1, and a corresponding electric heater (not shown in the figure) is installed in the heat exchange tank 2. The electric heater is in the prior art, so it is not included here. To reiterate, a liquid heat exchange medium, that is, heat conduction oil or heat conduction water, is added to the heat exchange tank 2, and heat conduction oil is selected in this case. The insulation layer 3 is made of glass wool insulation material.

[0022] There are three pump bodies II5 and one pump body I4 evenly distributed on the outside of the middle and lower parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com