Potential energy recovery system of division type electro-hydraulic drive forklift and division type electro-hydraulic drive forklift

A potential energy recovery and energy recovery technology, applied in fluid pressure actuating devices, lifting devices, servo motors, etc., can solve problems such as affecting the stability of the hydraulic system, reducing controllability, increasing energy loss, etc., to improve energy recovery capabilities. , Improve the effect of large energy loss and improve maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

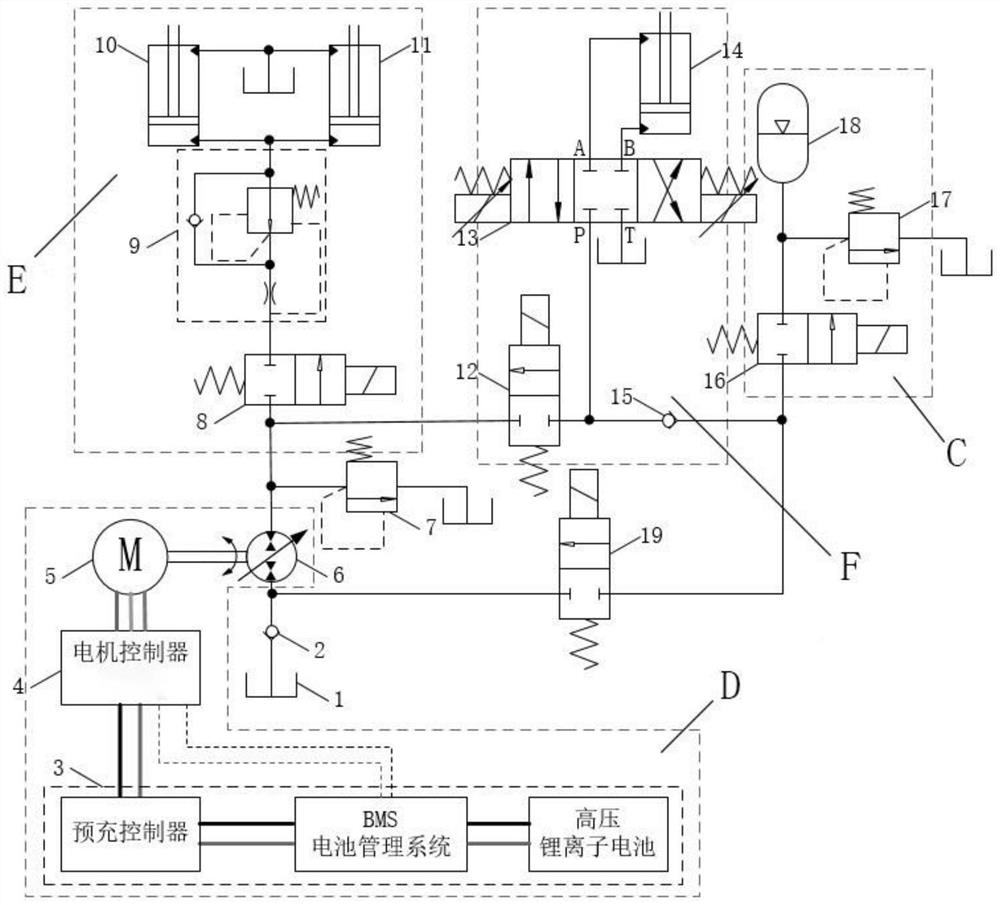

[0029] combine figure 1 , this embodiment provides a split-type electro-hydraulic drive forklift truck, including a fork, and also includes a split-type electro-hydraulic drive forklift potential energy recovery system, wherein the split-type electro-hydraulic drive forklift potential energy recovery system The first hydraulic 10 The push rods of the oil cylinder, the second hydraulic oil cylinder 11 and the tilting hydraulic oil cylinder 14 are connected to the fork, and are configured to drive the fork to move up and down and tilt and rotate. The split-type electro-hydraulic drive forklift potential energy recovery system includes a lifting oil circuit E, a tilting oil circuit F, a hydraulic drive and energy recovery assembly C, and an electrical drive and energy recovery assembly D; wherein, the lifting oil circuit E includes a first hydraulic cylinder 10 and a second hydraulic cylinder 11, the first hydraulic cylinder 10 and the second hydraulic cylinder 11 are suitable fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com