Rare earth doped tungsten bronze structural ceramic material with high energy storage property and preparation method of rare earth doped tungsten bronze structural ceramic material

A ceramic material and a rare earth doping technology, applied in the preparation of the ceramic material and the rare earth doped tungsten bronze structure ceramic material field, can solve the problems of low breakdown field strength, limited energy storage performance, low degree of relaxation, etc. The effect of low manpower and site requirements, reduced energy dissipation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

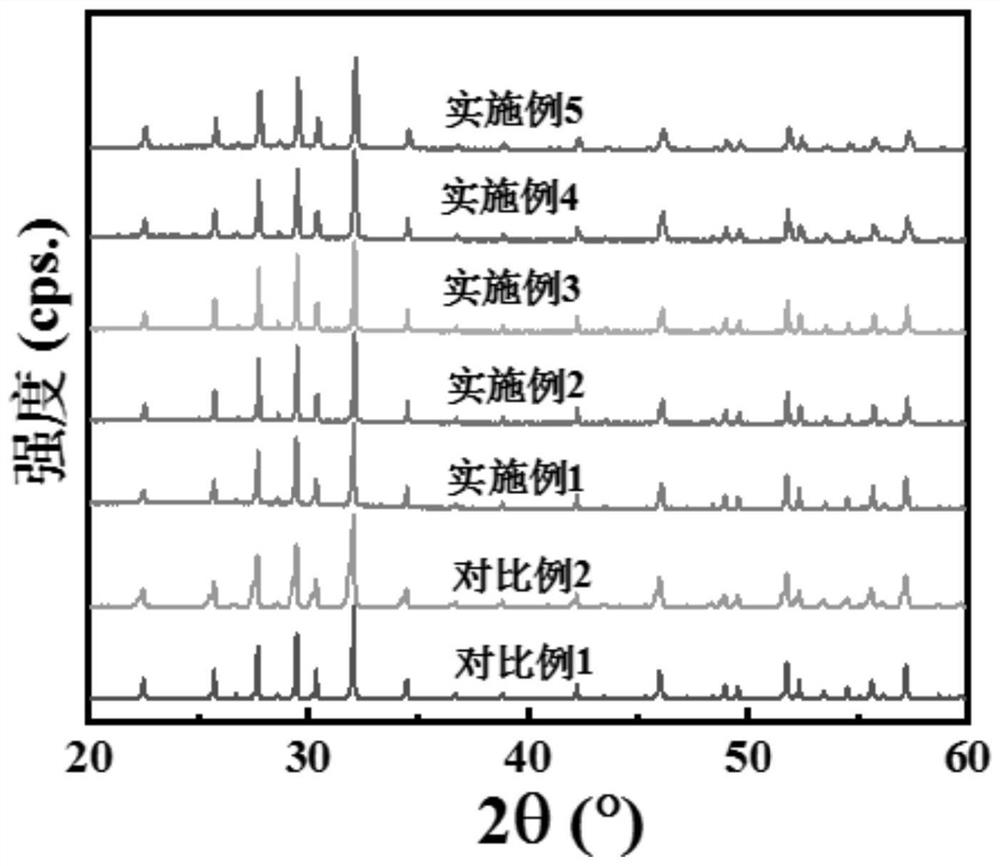

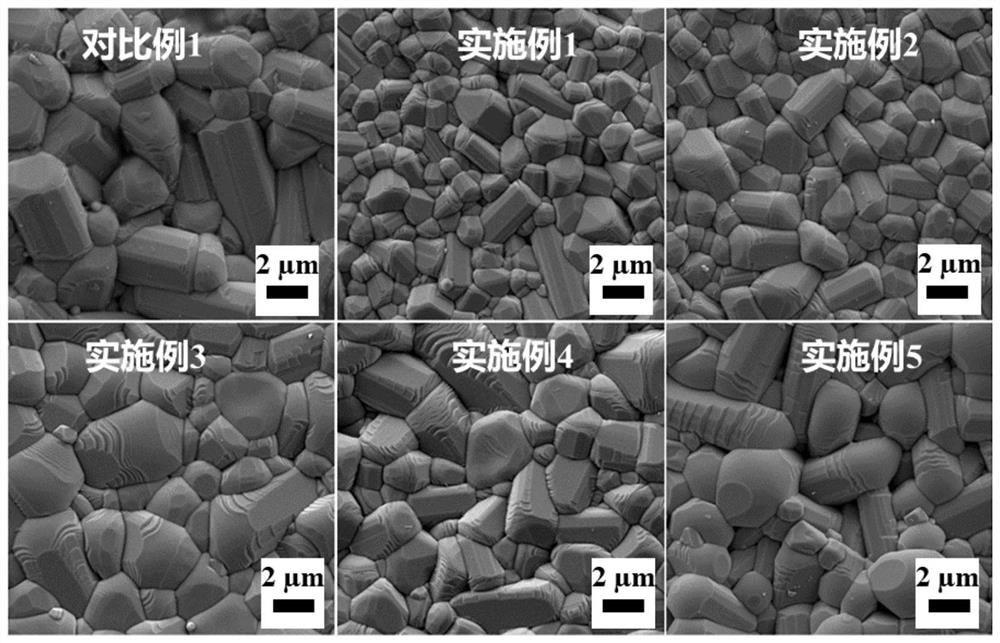

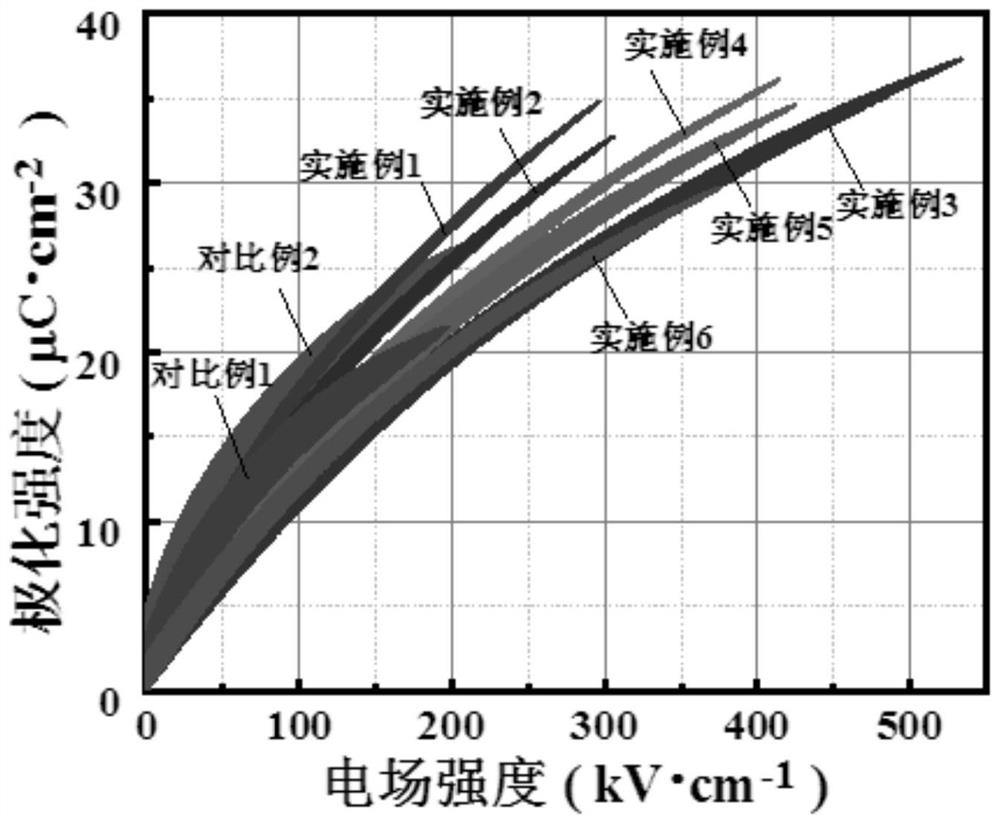

Embodiment 1

[0037]A preparation method of a rare earth-doped tungsten bronze structural ceramic material with high energy storage properties of the present invention is specifically implemented according to the following steps:

[0038] Step 1, according to (Sr 0.485 Ba 0.47 Gd 0.03 ) 0.98 La 0.02 Nb 2 O 6 The stoichiometry of SrCO with a purity of 99.00% was weighed 3 2.4350g BaCO with a purity of 99.00% 3 3.1291g of Nb with a purity of 99.90% 2 O 5 9.1409g La with a purity of 99.99% 2 O 3 0.1119g, 99.99% pure Gd 2 O 3 0.1831g, put it into a nylon jar, use zirconium balls as grinding balls and absolute ethanol as ball milling media, use a ball mill at 400 rpm for 16 hours, place it in a drying box to dry at 80 °C for 15 hours, and grind it with a mortar for 30 hours. minutes, passed through an 80-mesh sieve to obtain a raw material mixture;

[0039] In step 2, the raw material mixture is placed in an alumina crucible and compacted with an agate rod, so that the compact...

Embodiment 2

[0042] In step 1 of this embodiment, according to (Sr 0.485 Ba 0.47 Gd 0.03 ) 0.98 Nd 0.02 Nb 2 O 6 The stoichiometry of SrCO with a purity of 99.00% was weighed 3 2.4344g BaCO with a purity of 99.00% 3 3.1283g Nb with a purity of 99.90% 2 O 5 0.1157g, 99.85% pure Ta 2 O 5 3.4517g Gd with a purity of 99.99% 2 O 3 0.2828g, other steps are the same as in Example 1, to obtain a Gd-Nd co-doped tungsten bronze structure ferroelectric energy storage ceramic material.

Embodiment 3

[0044] In step 1 of this embodiment, according to (Sr 0.485 Ba 0.47 Gd 0.03 ) 0.98 Sm 0.02 Nb 2 O 6 The stoichiometry of SrCO with a purity of 99.00% was weighed 3 2.4344g BaCO with a purity of 99.00% 3 3.1283g Nb with a purity of 99.90% 2 O 5 9.1386g Sm with a purity of 99.999% 2 O 3 0.1197g, 99.99% pure Gd 2 O 3 0.1830g, and other steps are the same as in Example 1, to obtain a Gd-Sm co-doped tungsten bronze structure ferroelectric energy storage ceramic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com