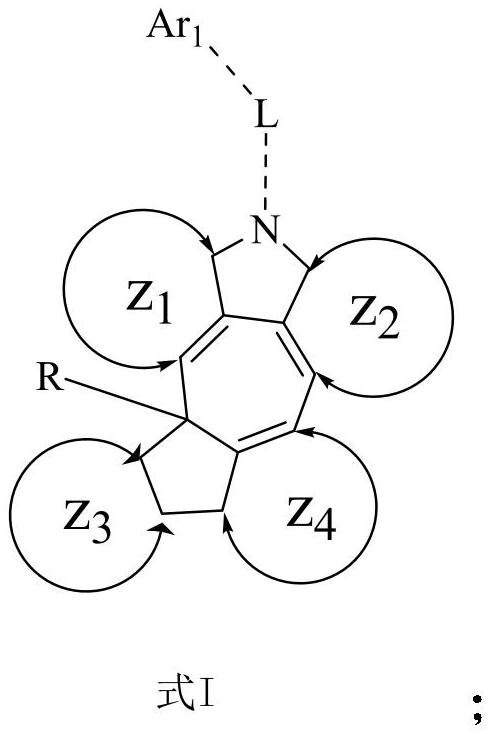

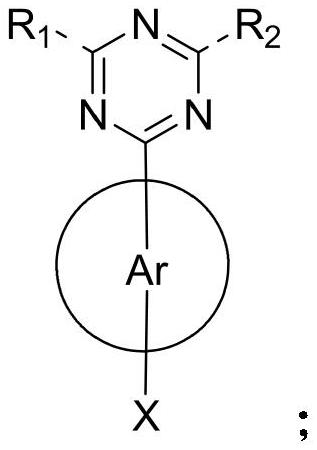

Organic electroluminescent material, preparation method thereof and organic electroluminescent device containing organic electroluminescent material

An electroluminescent material and luminescent technology, applied in luminescent materials, electric solid devices, organic chemistry, etc., can solve the problems of efficiency drop, triplet-polaron annihilation, triplet annihilation, etc., to reduce the driving voltage , good carrier mobility, and the effect of improving luminous efficiency and lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

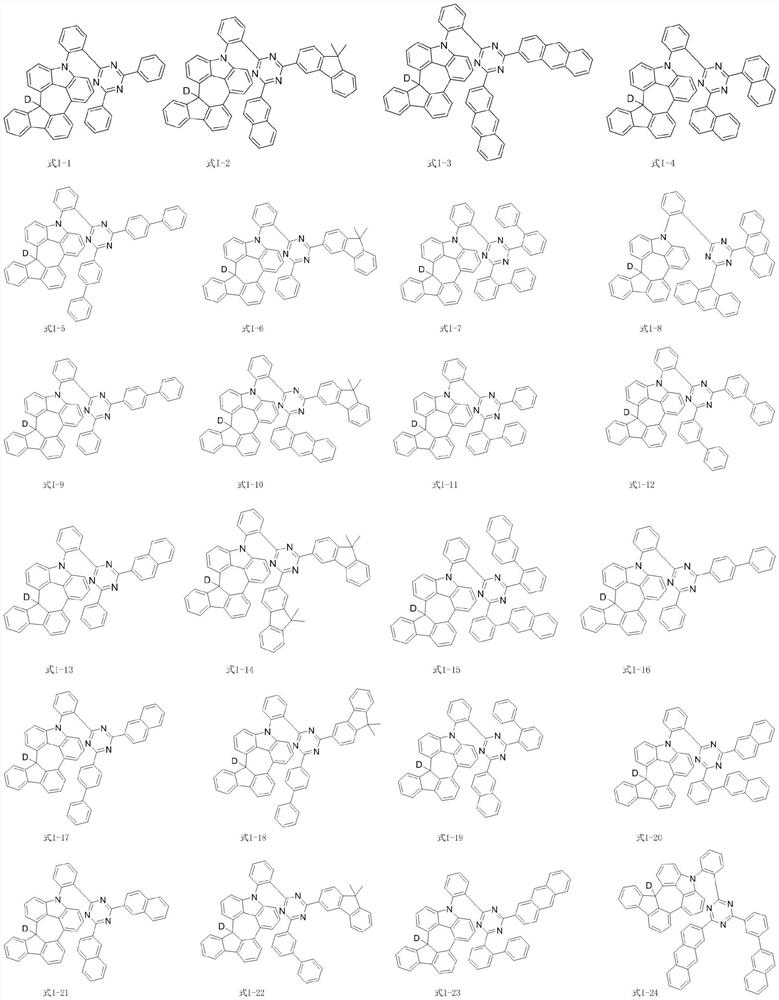

[0051] Preparation formula Chinese formula I-1, its concrete synthesis step is as follows:

[0052]

[0053]Under nitrogen protection system, weigh formula I-1a (153.85mmol, 50g), formula I-1b (169.23mmol, 52.83g), sodium tert-butoxide (430.77mmol, 41.4g) into the reaction system, add 500ml Toluene, catalyst Pd under nitrogen protection 2 (dba) 3 (6.15mmol, 3.54g) and (50%) P(t-Bu) 3 (6.15mmol, 1.25g), refluxed at 110°C for 22h under nitrogen protection, then cooled to 25°C, the organic phase was passed through a 200g silica gel funnel, the organic phase filtrate was spun until no liquid flowed out, 100ml of dichloromethane was added to dissolve, and the Solution column chromatography (200~300 mesh, 1000g) developing agent DCM:PE=1:1, spin the receiving liquid until no liquid flows out, add petroleum ether and stir for 20min, suction filter, rinse the filter cake with petroleum ether, filter The cake was vacuum-dried to obtain the compound formula I-1c (82.4 g, yield 84....

Embodiment 2

[0059] Preparation formula Chinese formula I-4, its concrete synthesis step is as follows:

[0060]

[0061] Under nitrogen protection system, weigh formula I-1a (94.87mmol, 50g), formula I-4b (104.35mmol, 43.02g), sodium tert-butoxide (265.63mmol, 25.53g) into the reaction system, add 500ml Toluene, catalyst Pd under nitrogen protection 2 (dba) 3 (3.79 mmol, 2.18 g) and (50%) P(t-Bu) 3 (3.79mmol, 0.767g), refluxed at 100°C for 19h under nitrogen protection, then cooled to 25°C, the organic phase was passed through a silica gel funnel of 200g silica gel, the organic phase filtrate was rotated until no liquid flowed out, 100ml of dichloromethane was added to dissolve, and the Solution column chromatography (200~300 mesh, 1000g) developing agent DCM:PE=2:1, spin the receiving liquid until no liquid flows out, add petroleum ether and stir for 20min, suction filter, the filter cake is rinsed with petroleum ether, the filter The cake was dried in vacuum to obtain the compound...

Embodiment 3

[0067] Preparation formula Chinese formula I-6, its concrete synthesis step is as follows:

[0068]

[0069] Under nitrogen protection system, weigh formula I-1a (94.87mmol, 50g), formula I-6b (104.35mmol, 44.7g), sodium tert-butoxide (265.63mmol, 25.53g) into the reaction system, add 50ml Toluene, catalyst Pd under nitrogen protection 2 (dba) 3 (3.79 mmol, 2.18 g) and (50%) P(t-Bu) 3 (3.79mmol, 0.767g), refluxed at 110°C for 22h under nitrogen protection, then cooled to 25°C, the organic phase was passed through a silica gel funnel of 200g silica gel, the organic phase filtrate was rotated until no liquid flowed out, 100ml of dichloromethane was added to dissolve, and the Solution column chromatography (200~300 mesh, 1000g) developing agent DCM:PE=2:1, spin the receiving liquid until no liquid flows out, add petroleum ether and stir for 20min, suction filter, the filter cake is rinsed with petroleum ether, the filter The cake was vacuum-dried to obtain the compound form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com