Flexible anaerobic adhesive suitable for large-gap curing and used for sealing pipe threads

A large gap, anaerobic adhesive technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of incomplete curing and slow curing of anaerobic adhesives, and achieve fast positioning speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

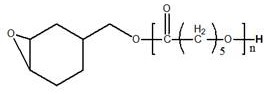

Method used

Image

Examples

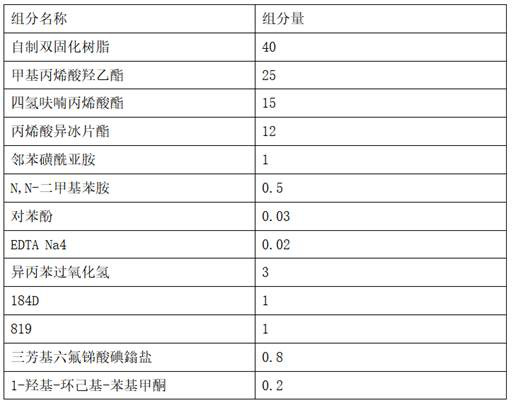

Embodiment 1

[0046]

[0047] In the present embodiment, the described preparation method is as follows:

[0048] (1) 40 parts of self-made dual-curing resin, 25 parts of hydroxyethyl methacrylate, 15 parts of tetrahydrofuran acrylate, and 12 parts of isobornyl acrylate were placed in a reaction kettle, under the condition of 25-30 ℃, at 300r / Stir at the speed of min for 30min to ensure uniform mixing.

[0049] (2) Add 1 part of o-benzenesulfonimide, 0.5 part of N,N-dimethylaniline, 0.03 part of p-phenol, and 0.02 part of EDTA Na4 into the stirring tank, under the condition of 25-30 ℃, at 600r / min Stir at the speed of 40min to ensure uniform stirring.

[0050] (3) Then 3 parts of cumene hydroperoxide, 1 part of 184D, 1 part of 819, 0.8 part of triaryl hexafluoroantimonate iodonium salt, and 0.2 part of 1-hydroxy-cyclohexyl-phenyl ketone were placed under a yellow light. Add it into the kettle under the condition of 25-30℃, stir at a speed of 600r / min for 40min to ensure uniform stirri...

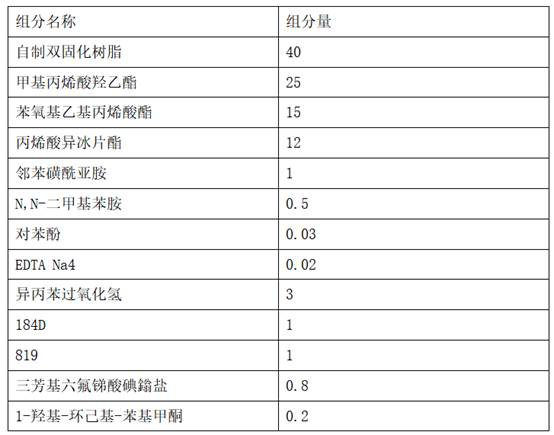

Embodiment 2

[0052]

Embodiment 3

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com