Color strip awning cloth and production process

A production process and tarpaulin technology, applied in the field of tarpaulin, can solve the problems of complex process, poor decoration, damage, etc., and achieve the effect of good softness, smooth coating and high composite degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

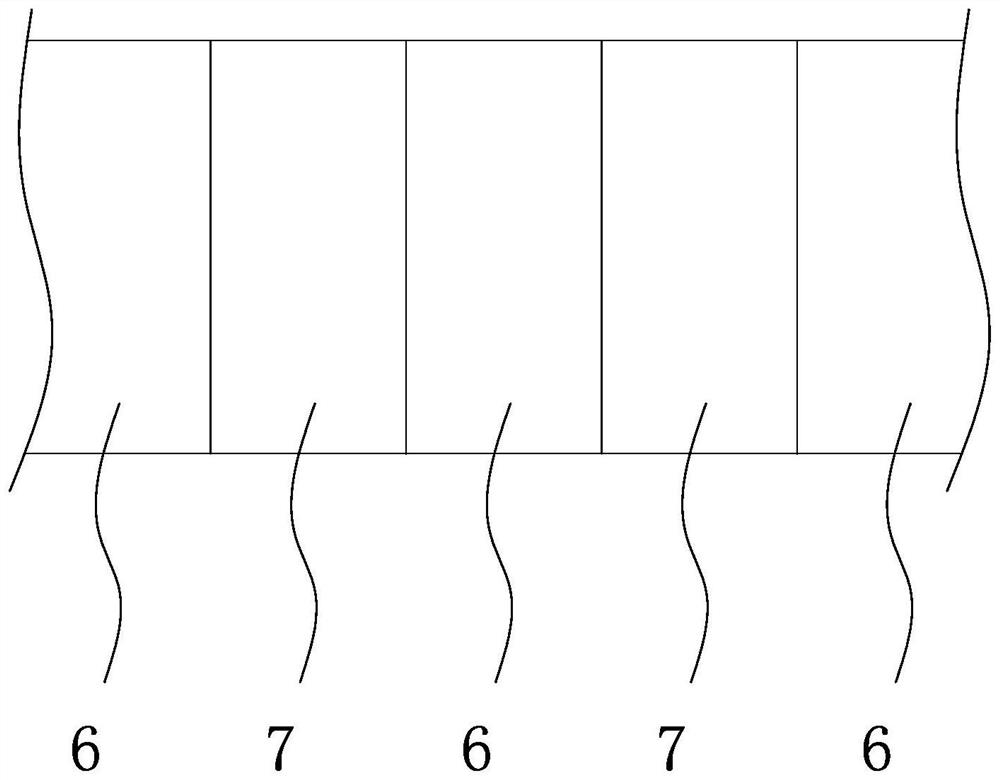

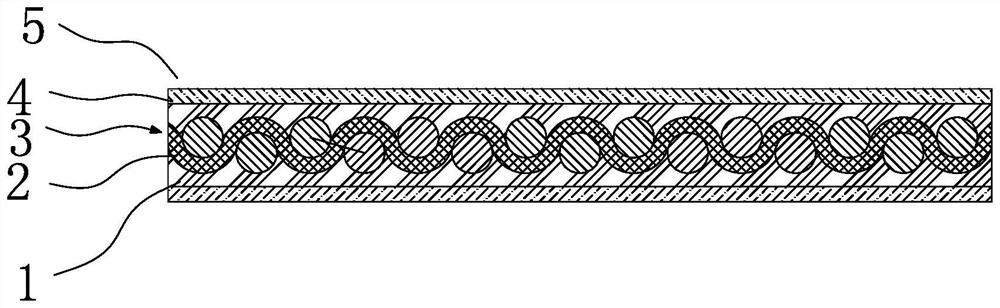

[0030] The present embodiment is a production process of a color-striped awning tarpaulin, which is characterized in that it consists of the following steps:

[0031] Step a, manufacture base cloth 3;

[0032] Step b, a surface coating: the front and back sides of the base cloth 3 are respectively coated with PVC paste to form a gray cloth;

[0033] Step c, primary gelation: the primary grey cloth is gelled in an oven, and the oven temperature is 150-170°C;

[0034] Step d, secondary surface coating: the reverse side of the primary grey cloth after the primary gel is coated with PVC paste to form a secondary grey cloth;

[0035] Step e, secondary gelation: gel the secondary grey cloth in an oven, and the oven temperature is 150-170°C;

[0036...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com