Groove silicon carbide MPS diode structure and preparation method thereof

A silicon carbide and diode technology, applied in the field of trench silicon carbide MPS diode structure and preparation, can solve the problems of not being able to further improve the anti-surge capability of the device, and cannot further reduce the forward conduction voltage drop of the device, so as to reduce the forward conduction Effect of pressure drop, increase in area, increase in area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The technical solutions of the present invention are further described below, but the claimed scope is not limited to the description.

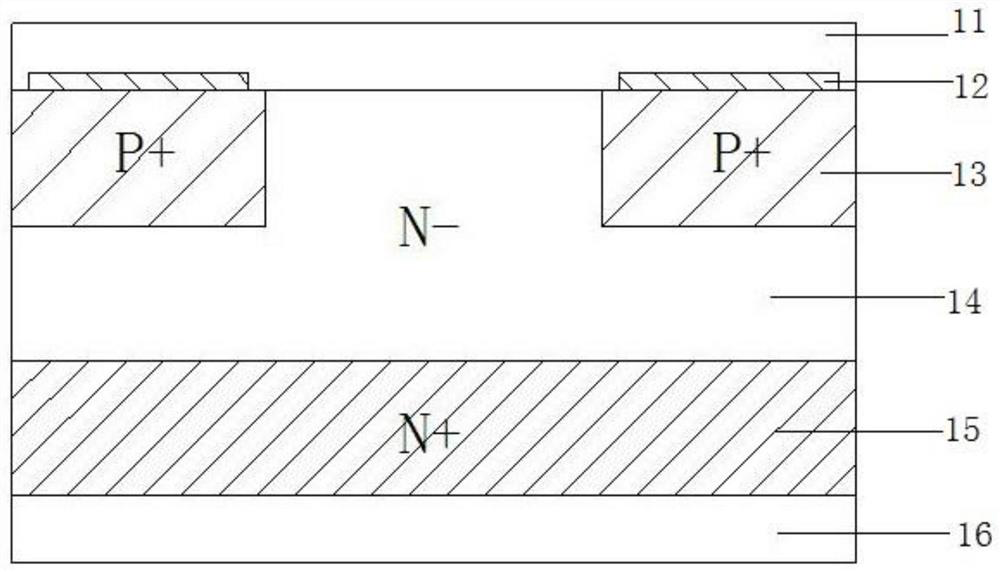

[0056] The present invention provides a trench silicon carbide MPS diode structure, comprising:

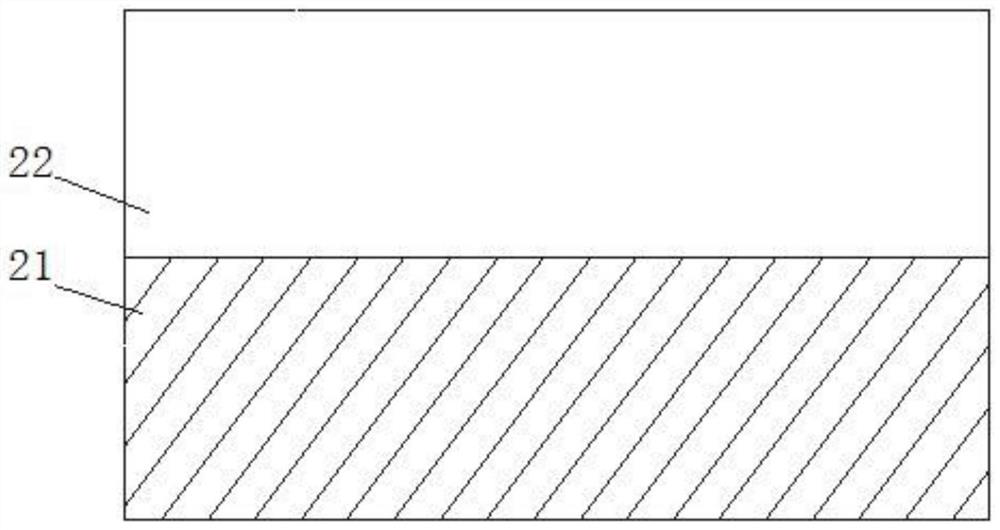

[0057] Silicon carbide N+ substrate 21 providing the substrate basis;

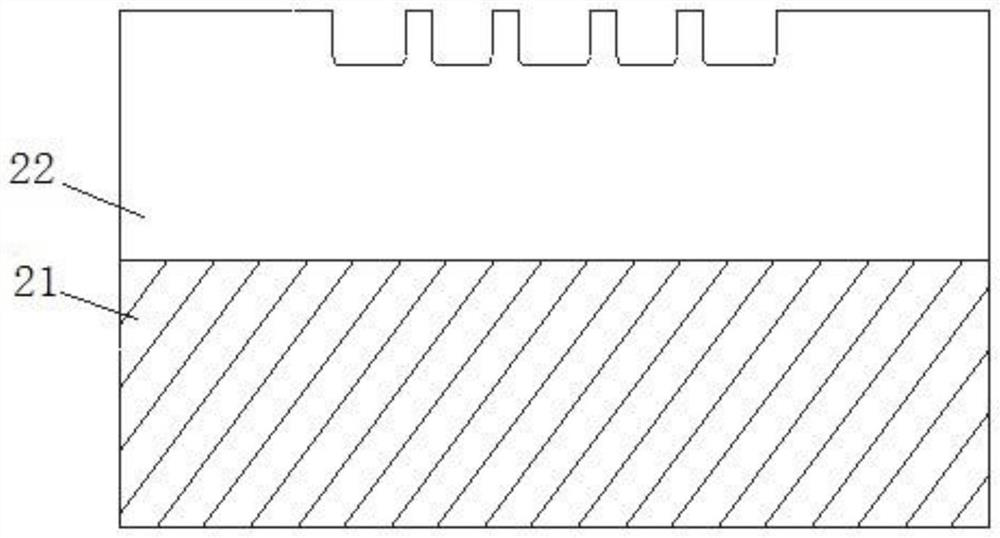

[0058] The silicon carbide epitaxial layer 22 located above the silicon carbide N+ substrate 21, the thickness of the silicon carbide epitaxial layer 22 is 5-20 μm;

[0059] A plurality of P+ field limiting rings 23 are located in the silicon carbide epitaxial layer 22 at intervals. The silicon carbide epitaxial layer 22 has grooves with a depth of 0.4 μm to 1.2 μm and a width of 1 μm to 5 μm to cooperate with the P+ field limiting rings 23 ;

[0060] The P+ trench region 24 is located in the periodically arranged silicon carbide epitaxial layer 22. The silicon carbide epitaxial layer 22 is periodically arranged with trenches. The depth of the trenches of the silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com