Air inlet system suitable for low-temperature quick start of fuel cell

A technology of quick start and air intake system, applied in the field of air intake system, can solve the problems of fuel cell start-up difficulty, slowness, and difficult reaction, and achieve the effects of preventing blockage, increasing reaction concentration, and reducing flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

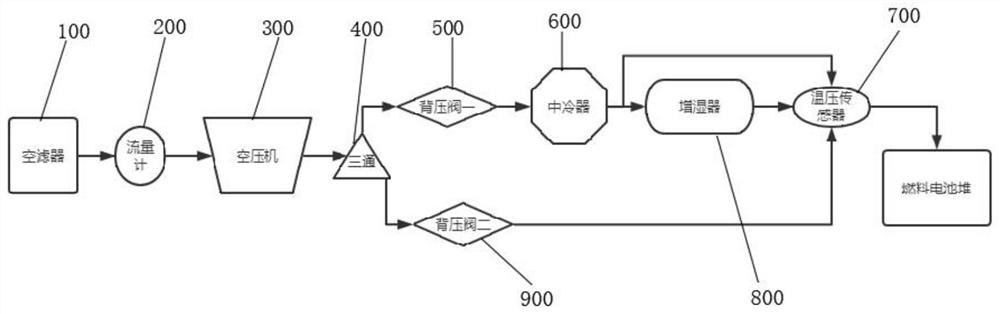

[0034] An air intake system suitable for low temperature and fast start-up of fuel cells, such as figure 1 As shown, the air filter 100 and the air compressor 300 are connected in sequence, and the air outlet of the air compressor 300 is respectively connected with a back pressure valve 1 500 and a back pressure valve 2 900 through a three-way 400. The back pressure valve 1 The air outlet of 500 is sequentially connected to the intercooler 600, the humidifier 800, and the temperature and pressure sensor 700. The air outlet of the temperature and pressure sensor 700 is connected to the air inlet of the fuel cell stack. The air port is connected to the air inlet of the temperature and pressure sensor 700 .

[0035] To solve traffic monitoring problems; such as figure 1 As shown, a flow meter 200 is installed on the connecting pipeline between the air filter 100 and the air compressor 300 .

[0036] In this embodiment, under normal conditions, the air compressor 300 compresses ...

Embodiment 2

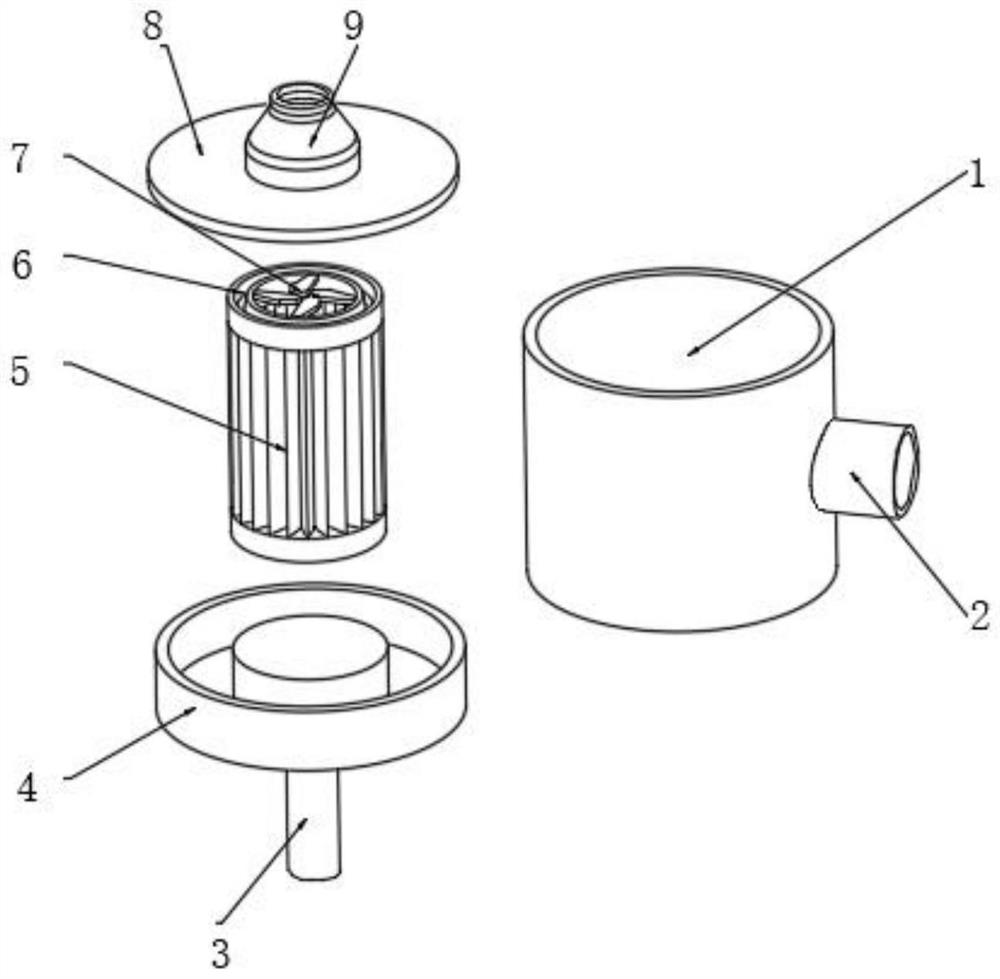

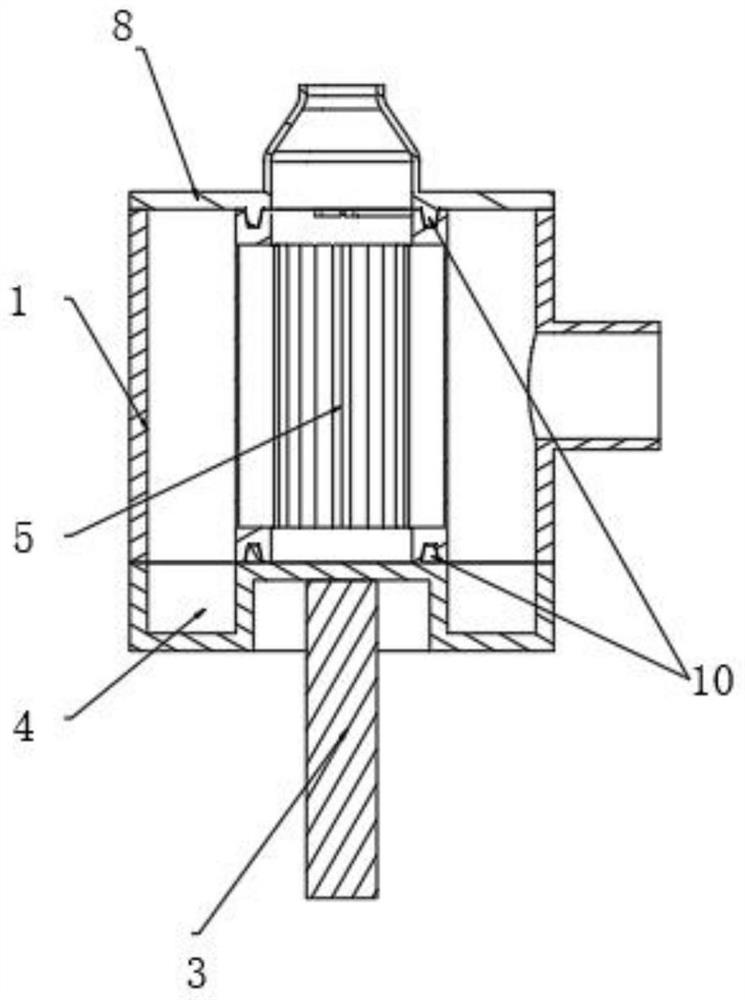

[0038] An air intake system suitable for low temperature and fast start-up of fuel cells, such as Figure 2-5 As shown in the figure, in order to solve the problem of air filtration; this embodiment makes the following improvements on the basis of Embodiment 1: the air filter 100 includes an outer casing 1, a grooved bottom cover 4 and a top cover respectively fixed on both sides of the outer casing 1 8 and the filter element 5 arranged inside the outer casing 1, the outer wall of the outer casing 1 is welded with an air inlet 2 communicating with its inner cavity. The outer wall of the top cover 8 is welded with an air outlet 9 arranged coaxially with it; After entering the surrounding inner wall of the outer casing 1 from the air inlet 2 , it is filtered by the filter element 5 and then flows out from the inside of the filter element 5 along the air outlet 9 .

[0039] In order to solve the problem of uniform use and prevent local clogging, such as figure 2 , 3As shown, t...

Embodiment 3

[0042] An air intake system suitable for low temperature and fast start-up of fuel cells, such as Figure 2-5 As shown in the figure, in order to solve the problem of blocking prevention; this embodiment makes the following improvements on the basis of Embodiments 1 and 2: the bottom of the groove bottom cover 4 is provided with a recoil type dust removal mechanism 3, and the recoil type dust removal mechanism 3 includes a cylinder 11 welded to the bottom of the groove bottom cover 4, a piston 19 slidably connected to the inner wall of the cylinder 11, and a telescopic piece 18 fixed to the outer wall of the bottom of the cylinder 11 by bolts. In this embodiment, the specific type of the telescopic element 18 is not limited, and it is preferably a cylinder. The telescopic element 18 can drive the piston 19 to move up and down, so as to apply a recoil force to the inner cavity of the filter element 5 and attach the filter to the filter element 5 through the recoil force. The pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com