Liquid cooling connection system

A connection system, liquid cooling technology, applied in cooling/ventilation/heating retrofit, climate sustainability, energy-saving calculation, etc., can solve problems such as difficult copper bars, cooling, etc., to improve flow capacity, facilitate interconnection, reduce The effect of material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0031] Referring to the accompanying drawings, the specific embodiments are as follows:

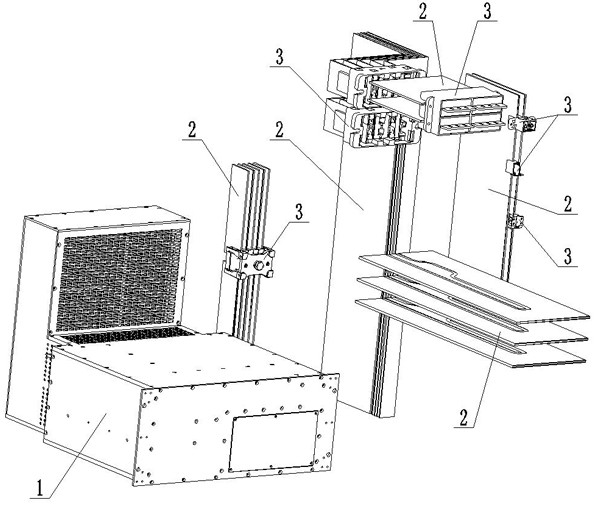

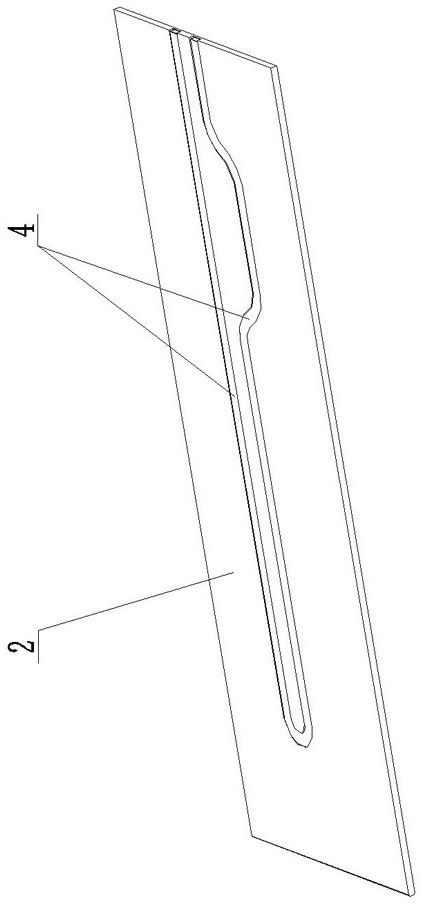

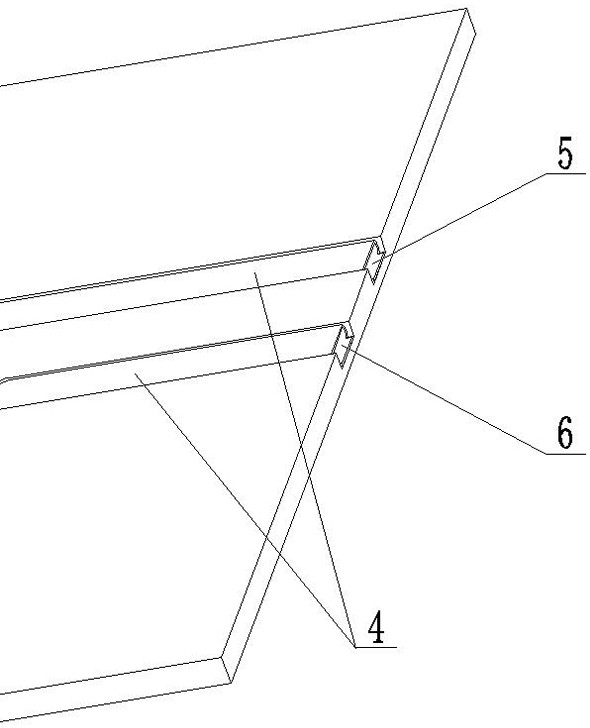

[0032] like figure 1 As shown, a liquid cooling connection system includes a copper bar assembly composed of one or more copper bars 2, and a connector assembly composed of one or more connectors 3, the input end and the output end of the connector 3 are respectively It is connected with copper bar 2 and conductors to realize electrical and heat transfer. There is a liquid cooling circuit on copper bar 2, and the liquid cooling circuit is connected with the liquid cooling source 1 or the liquid cooling circuit on other copper bars 2 to form a cooling circuit. The cooling liquid circulation passage for cooling the copper bar assembly.

[0033] figure 1 sets of different busbar assemblies and different connector assemblies are shown in , and figure 1 The piping for coolant flow is omitted. The liquid cooling source 1 is to provide the whole liquid cooling system with circulating cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com