Method for operating air separation plant having distillation column system, heat exchanger and adsorber, and air separation plant

A technology of heat exchanger and air separation, which is applied to the corresponding air separation equipment, even if it is stopped for a long time, the "main heat exchanger" is characterized in the field and can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

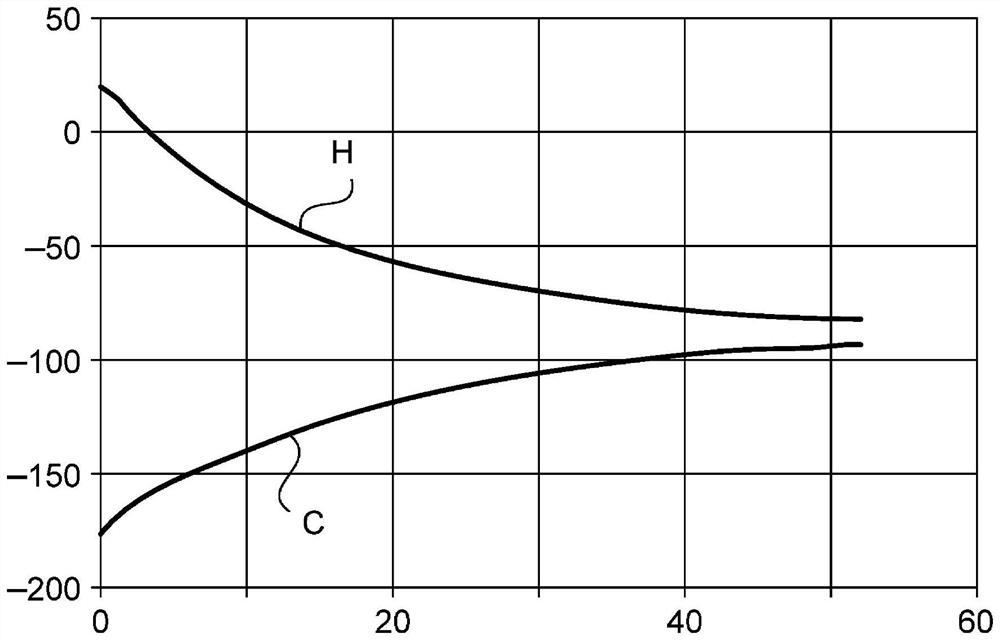

[0054] figure 1 In the form of a temperature diagram, the temperature profile of the heat exchanger after a shutdown without the use of the measures according to an advantageous embodiment of the invention is shown.

[0055] exist figure 1 In the figures shown, the temperature at the hot end, marked with H, and the temperature at the cold side, marked with C, of the corresponding heat exchanger are each shown in °C on the ordinate, while the temperature at the cold end, marked with C, is shown on the abscissa. time in hours.

[0056] like figure 1 As seen in the outage, the temperature H at the hot end of the heat exchanger at the beginning of the shutdown is about +20°C, which also corresponds to the temperature at which the heat exchanger operates normally, and the temperature C at the cold end is about -175°C °C. As time increases, these temperatures equilibrate with each other. The high thermal conductivity of the materials used in heat exchangers is the reason for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com