Substrate with anti-glare layer, image display device, and method for producing substrate with anti-glare layer

An anti-glare layer and base material technology, which is applied in the field of base material manufacturing, can solve the problems of reduced visual recognition of images, and achieve the effects of excellent coating and adhesion, excellent anti-glare function, and good visual recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

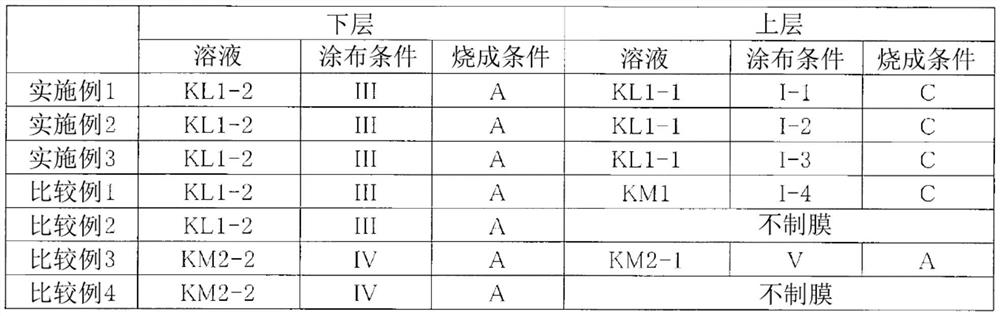

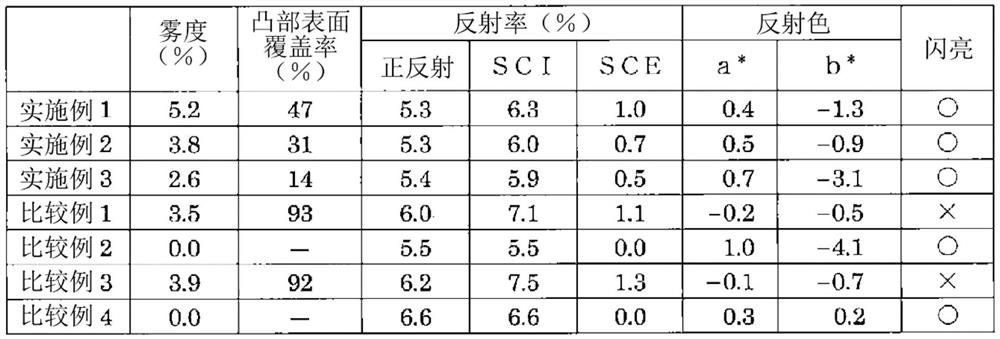

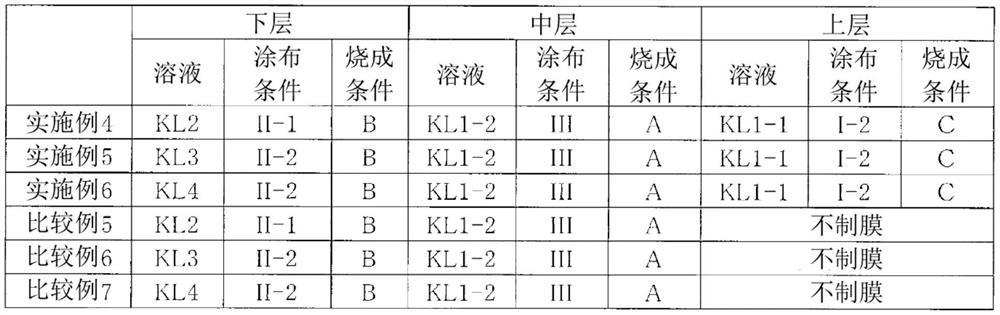

[0127] Although an Example is given below and this invention is demonstrated in detail, it is not limited to these.

[0128] Abbreviations used below are as follows.

[0129] TEOS: Tetraethoxysilane.

[0130] F13: Tridecafluorooctyltrimethoxysilane.

[0131] UPS: gamma-ureidopropyltriethoxysilane.

[0132] TTE: titanium tetraethoxide.

[0133] AN: Aluminum nitrate nonahydrate.

[0134] MeOH: methanol.

[0135] EtOH: Ethanol.

[0136] IPA: isopropyl alcohol.

[0137] PGME: Propylene Glycol Monomethyl Ether.

[0138] BCS: Butyl Cellosolve.

[0139] PB: propylene glycol monobutyl ether.

[0140] PG: Propylene glycol.

[0141] HG: 2-methyl-2,4-pentanediol.

[0142] NMP: N-methyl-2-pyrrolidone.

Synthetic example 1

[0144] TEOS (31.6 g), F13 (6.2 g), and MeOH (30.3 g) were added to a 200 mL four-neck flask equipped with a reflux tube, followed by stirring, and MeOH (15.1 g), water (15.0 g), and oxalic acid ( 0.8 g) and stirred in an ice bath at 10°C for 30 minutes. Then, it stirred at 65 degreeC for 2 hours, then, UPS (0.5g) and MeOH (0.5g) were added, and it was made to react at 65 degreeC for 2 hours. Then, it was left to cool to room temperature, and the solution K1 was obtained.

Synthetic example 2

[0146] AN (2.9 g), water (2.6 g), and EtOH (50.6 g) were added to a 200-mL volumetric flask and stirred to obtain an AN solution. To this AN solution was added TEOS (21.2 g), followed by stirring at room temperature for 30 minutes. Then, TTE (10.0g) and EtOH (12.7g) were added, and it stirred at room temperature for 30 minutes, and obtained the solution K2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com