Unbalance load balancing device suitable for double-brush operation of wall cleaning vehicle and control method

A technology for balancing devices and cleaning vehicles, which is applied to tractors, motor vehicles, transportation and packaging, etc. It can solve problems such as rollover, unbalanced load of the whole vehicle, self-heavyness, etc., and achieve safety assurance, pressure reduction, and high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

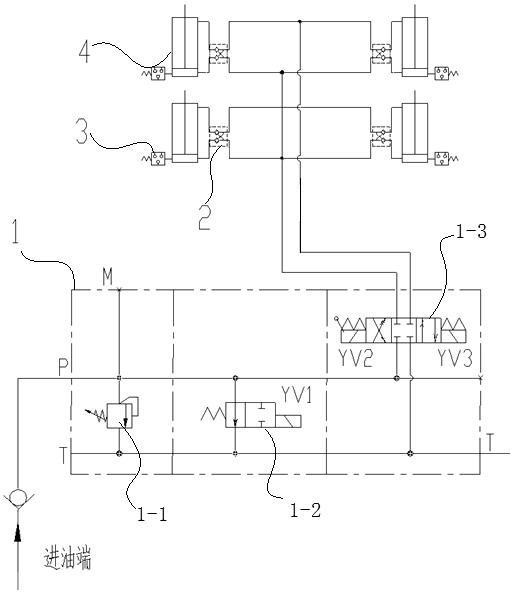

[0027] combine figure 1 As shown, four stabilizers 4 are included, two are respectively installed on the front axle and the rear axle of the vehicle, and the four stabilizers 4 are arranged in a rectangular shape. The stabilizer 4 is installed on the side of the bodywork sub-beam above the spring steel plate of the front axle or rear axle of the vehicle. The stabilizer 4 adopts a hydraulic cylinder; the piston rod head of the hydraulic cylinder faces the spring steel plate, and there is a distance between the piston rod head and the spring steel plate to avoid The piston rod head is in contact with the vehicle while it is not working. .

[0028] The control valve group 1 has an oil inlet P and an oil return port T, and the oil inlet of the control valve group 1 is connected to a high-pressure oil source. The control valve group 1 includes a relief valve 1-1, a pressure maintaining valve 1-2 and a reversing valve 1-3. The oil inlet of the relief valve 1-1 is connected to the...

Embodiment 2

[0032] An eccentric load control method suitable for the double-brush operation of a wall cleaning vehicle, on the basis of the above-mentioned first embodiment, the steps are as follows:

[0033] Work posture preparation stage;

[0034] When the vehicle is ready to start cleaning, prepare the boom working posture; at this time, the electromagnet YV1 of the pressure-retaining valve 1-2 of the control valve group 1 is energized, and the system starts to build pressure;

[0035] The reversing valve 1-3 of the control valve group 1 is powered on to the electromagnet YV3, and the hydraulic oil enters the rodless cavity of the stabilizer 4 through the plate hydraulic lock 2, and the stabilizer 4 extends in place;

[0036] job monitoring status;

[0037] After the vehicle completes the work posture preparation, the reversing valve 1-3 electromagnet YV3 of the control valve group 1 is de-energized, and the position of the solenoid valve spool is as follows: figure 1 shown;

[0038...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com