Europium ion multivalent double-center optical temperature probe material

A temperature probe, multi-valence technology, applied in the field of non-contact optical temperature measurement materials, can solve the problems of harsh material requirements, difficult luminescence center, inability to take into account temperature measurement sensitivity and signal discrimination ability, etc., to achieve high luminous efficiency, High temperature sensitivity and good physical and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

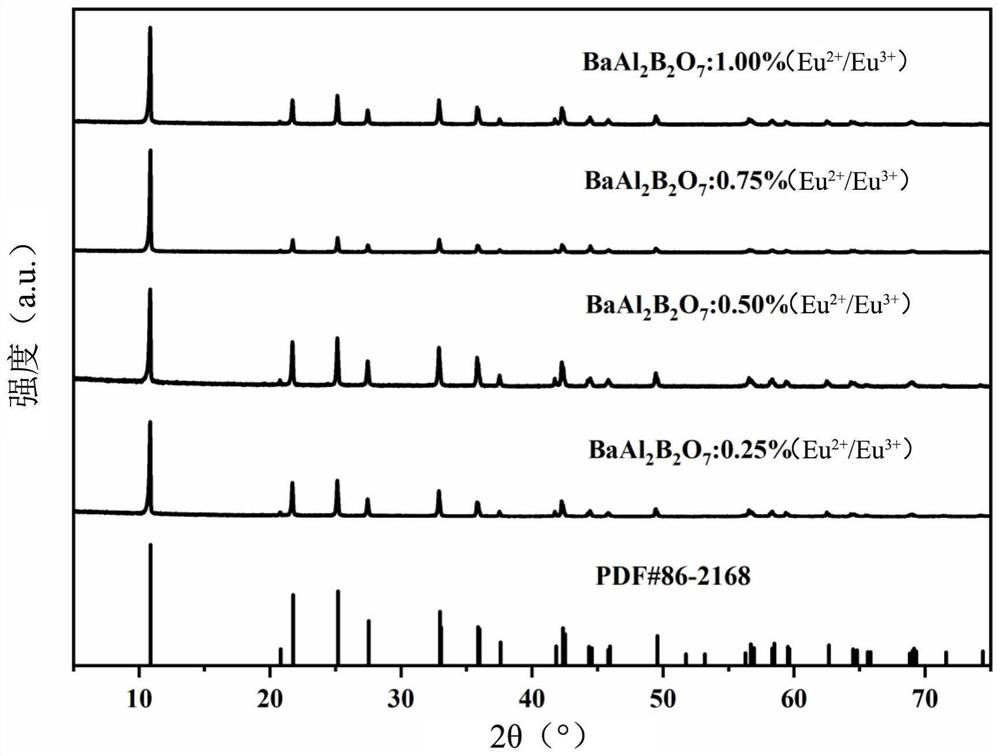

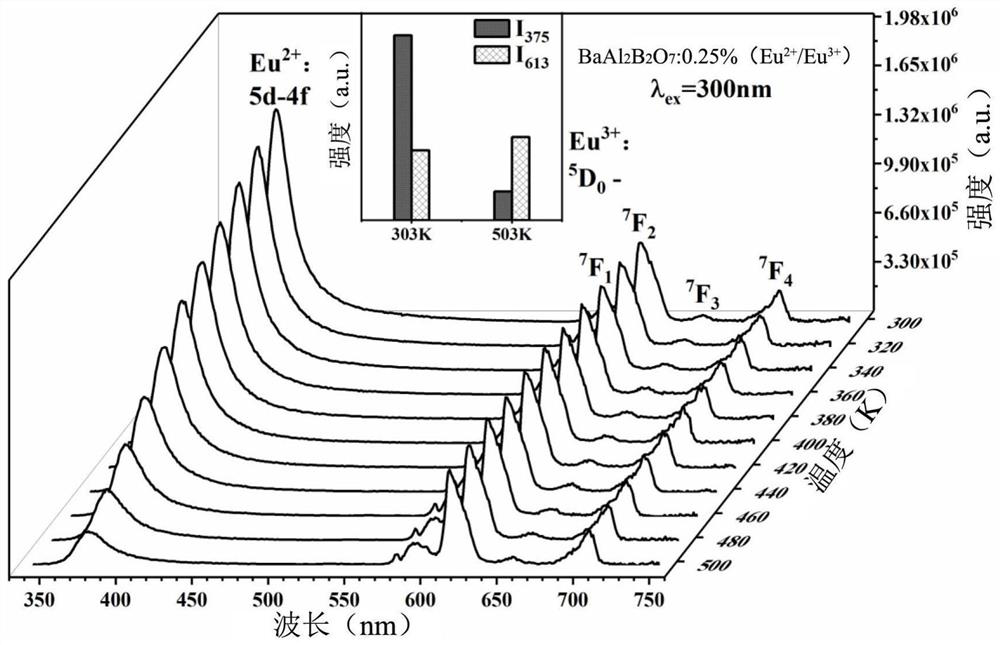

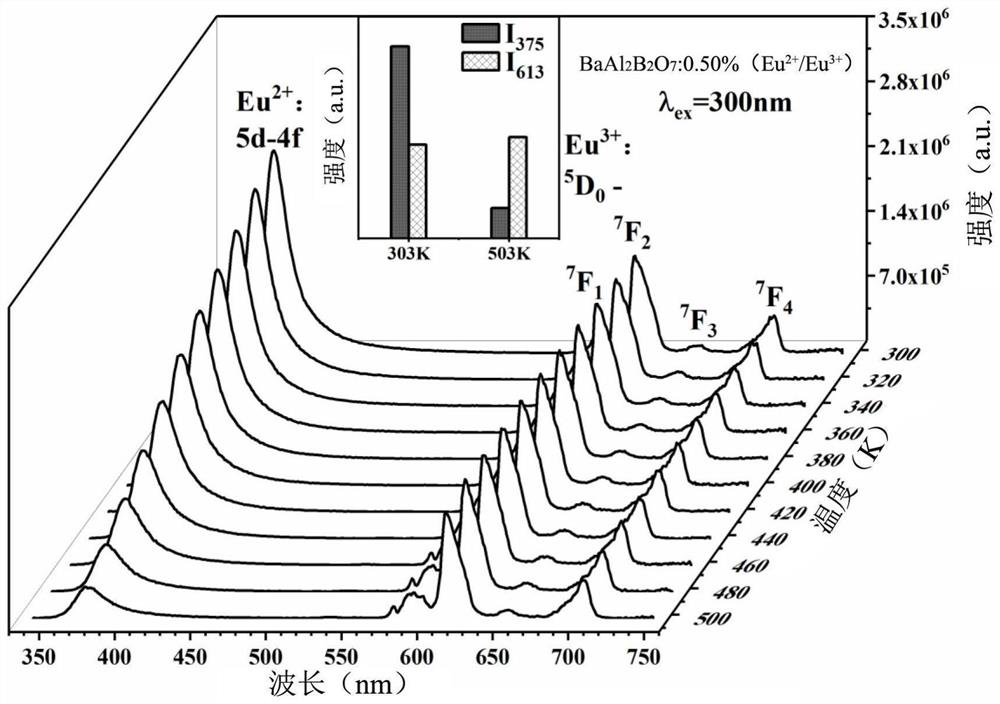

[0047] Weigh BaCO 3 4mmol, Al 2 O 3 2mmol, H 3 BO 3 4mmol, Eu 2 O 3 (0.005, 0.010, 0.015, 0.02) mmol were ground in an agate mortar for 20 min and mixed well, then embedded with carbon powder (0.8 g, about 16 wt % of the total weight of the raw materials), placed in a corundum crucible, and placed in a 900 calcined in a muffle furnace at ℃ for 4 h, cooled to room temperature, taken out, ground and dispersed to obtain an optical temperature probe material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com