Method for simultaneously separating gasoline and diesel components by simulated moving bed

A simulated moving bed and simultaneous separation technology, applied in the petroleum industry, refined hydrocarbon oil, etc., can solve the problems of olefin or aromatic resource waste, complex process flow, large equipment investment, etc., achieve low desorbent consumption, high separation purity, The effect of low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

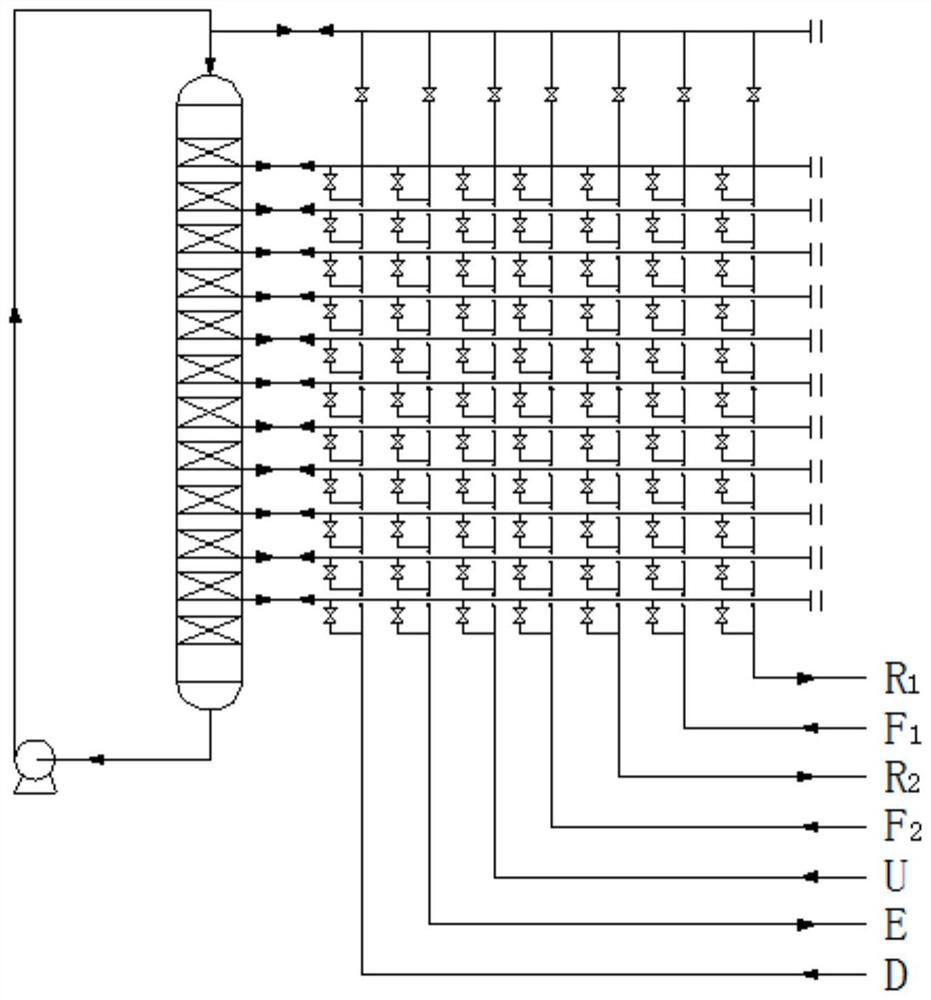

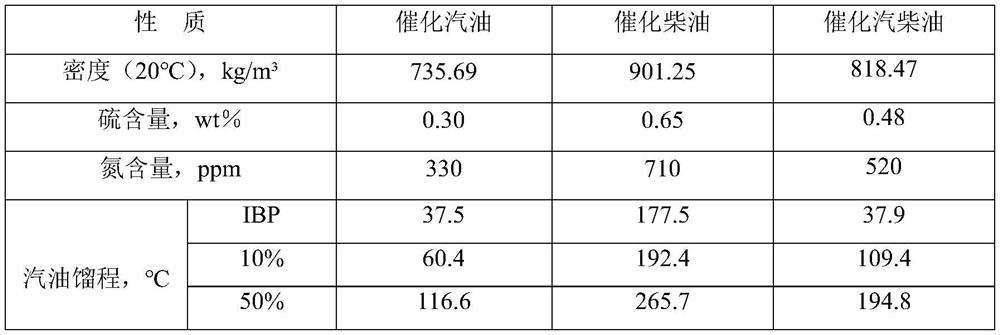

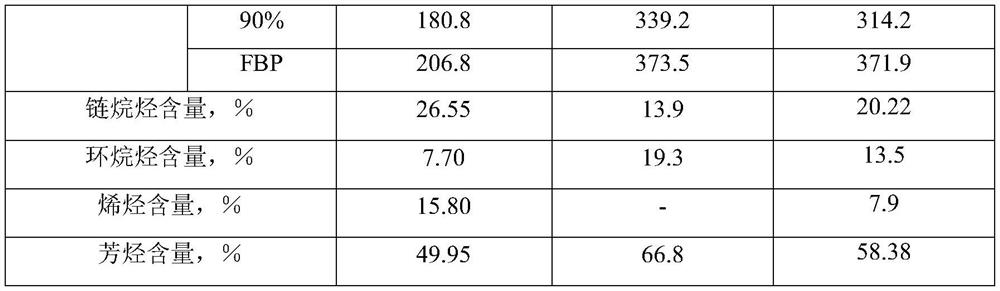

[0043] Referring to the accompanying drawings, the adsorption tower is divided into 12 beds according to the liquid flow direction, and each bed is connected with 5 material inlet and outlet pipelines, including gasoline and diesel mixed raw materials F2, desorbent D, raffinate R1, extraction liquid E, flushing liquid U, the whole adsorption tower is divided into four zones, the adsorption zone, the refining zone, the desorption zone and the isolation zone are set according to the number of 3-4-3-2 bed layers. The gasoline and diesel mixed feedstock F2 is first injected into the top bed of the adsorption zone. After the material passes down the aromatic hydrocarbon adsorbent, the gasoline and diesel aromatic components are adsorbed on the adsorbent to obtain high-purity gasoline and diesel non-aromatic components from the bottom bed of the adsorption zone. The layer is extracted as raffinate R1 (non-aromatic hydrocarbon components); the adsorbed aromatic hydrocarbon adsorbent e...

Embodiment 2

[0057] Referring to the accompanying drawings, the adsorption tower is divided into 12 beds according to the liquid flow direction, and each bed is connected with 6 material inlet and outlet pipelines, including diesel raw material F1, gasoline raw material F2, desorbent D, raffinate R1, extraction liquid E, For the flushing liquid U, the entire adsorption tower is divided into five zones, the adsorption zone I, the adsorption zone II, the refining zone, the desorption zone and the isolation zone are set according to the number of 3-3-1-3-2 bed layers. Diesel feedstock F1 and gasoline feedstock F2 are first injected into the top bed of adsorption zone I and the top bed of adsorption zone II, respectively. After the material passes through the aromatic hydrocarbon adsorbent downward, the gasoline and diesel aromatics components are adsorbed on the adsorbent, among which the gasoline The non-aromatic components replace the diesel non-aromatic components on the aromatic adsorbent ...

Embodiment 3

[0066] Referring to the accompanying drawings, the adsorption tower is divided into 12 beds according to the liquid flow direction, and each bed is connected with 6 material inlet and outlet pipelines, including gasoline raw material F1, diesel raw material F2, desorbent D, raffinate R1, extraction liquid E, For the flushing liquid U, the entire adsorption tower is divided into five zones, the adsorption zone I, the adsorption zone II, the refining zone, the desorption zone and the isolation zone are set according to the number of 3-3-1-3-2 bed layers. The gasoline feedstock F1 and diesel feedstock F2 are first injected into the top bed of the adsorption zone I and the top bed of the adsorption zone II respectively. After the material passes through the aromatic hydrocarbon adsorbent downward, the diesel oil and gasoline aromatics components are adsorbed on the adsorbent, among which the diesel oil is adsorbed on the adsorbent. The non-aromatic components replace the gasoline n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com