Forward and reverse screw shuttle type free piston engine

A technology of piston engine and positive and negative screw, which is applied in the direction of free piston engine, internal combustion piston engine, combustion engine, etc. It can solve the problems of large space occupation, high engine height, and large loss of mechanical energy, so as to achieve small loss of mechanical energy and low fuel consumption. The effect of less mechanical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

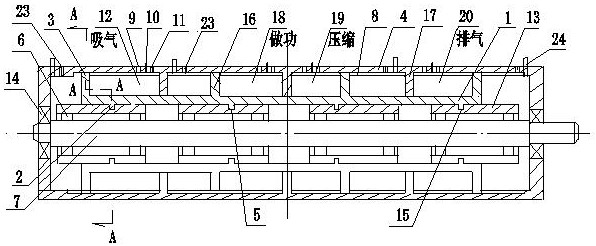

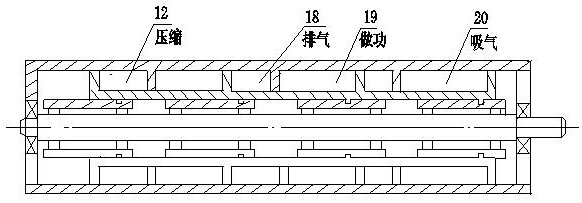

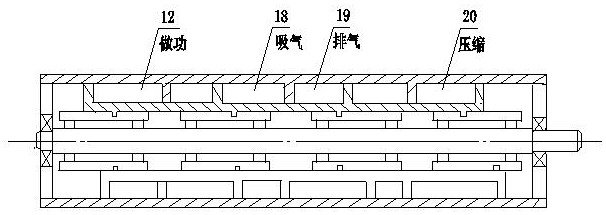

[0024] exist Figure 1 to Figure 7, the forward and reverse screw shuttle type free piston engine, which includes a rotating shaft 7 assembled on both ends of the cylinder block with common bearing assemblies 14 at both ends of the cylinder block 4, and four one-way bearing assemblies 6 are fixed on the rotating shaft at intervals. The drum 13 located in the inner cavity of the cylinder, the outer surfaces of the two drums on the left are respectively provided with left helical grooves 5 with a square or trapezoidal cross-section, and the outer surfaces of the two drums on the right are respectively provided with The cross section is a square or trapezoidal right helical groove 15, the length of the drum is slightly longer than the distance between the left dead center 21 and the right dead center 22, a piston 1 is arranged between the drum and the cylinder, and the inner circle of the piston is On the surface of the hole, there are four driving blocks 2 which are vertically s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com