Seal device with lid

A standard part, the technology of the exhaust pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

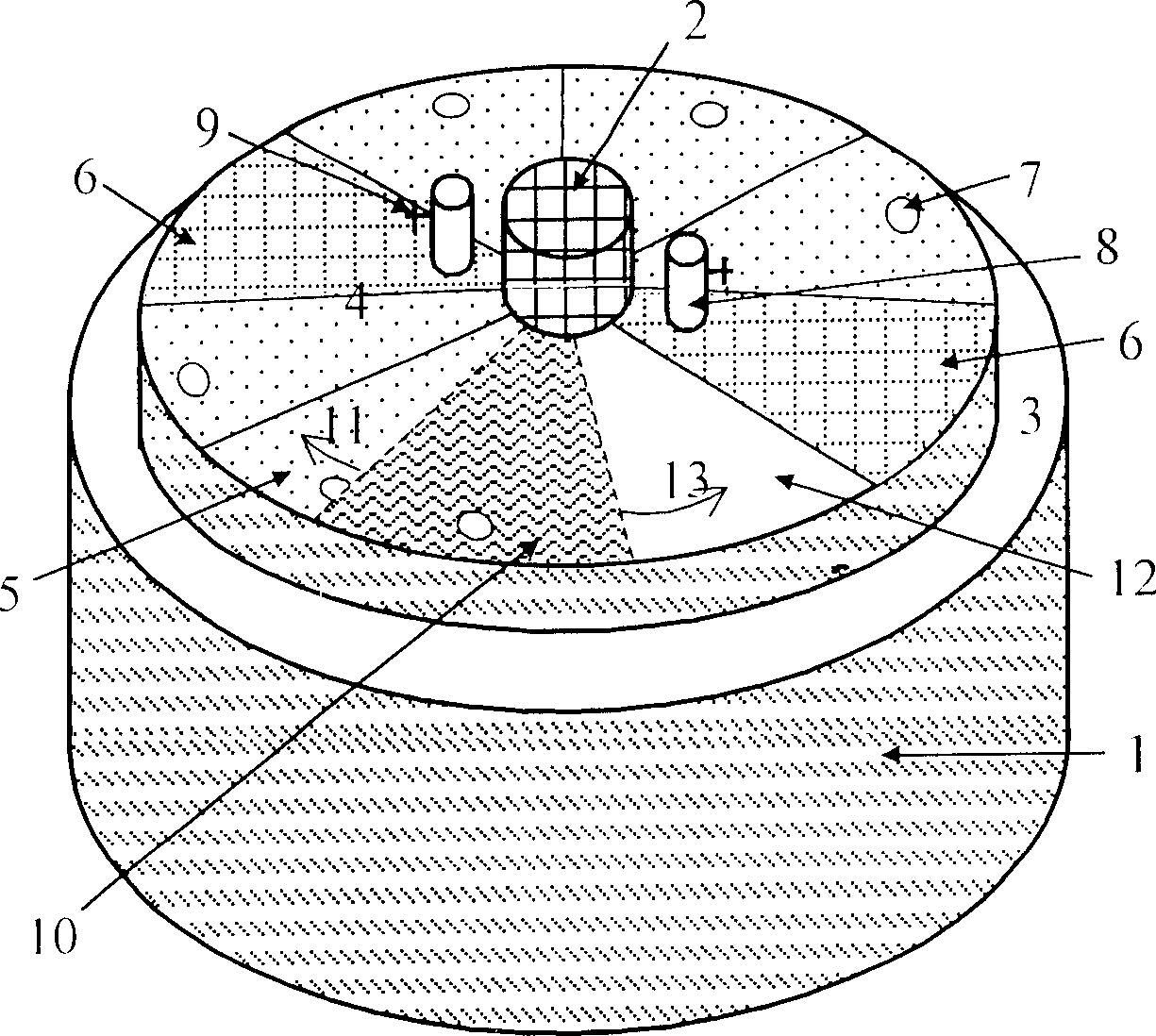

[0018] The surface aeration tank, the water treatment facility used for surface aeration reaction in the drainage workshop of petroleum refining enterprises, often emits waste gas containing hydrogen sulfide, benzene, and volatile hydrocarbons. By using the device of the invention, the surface aeration tank can be sealed to collect waste gas so as to facilitate sampling monitoring and purification treatment.

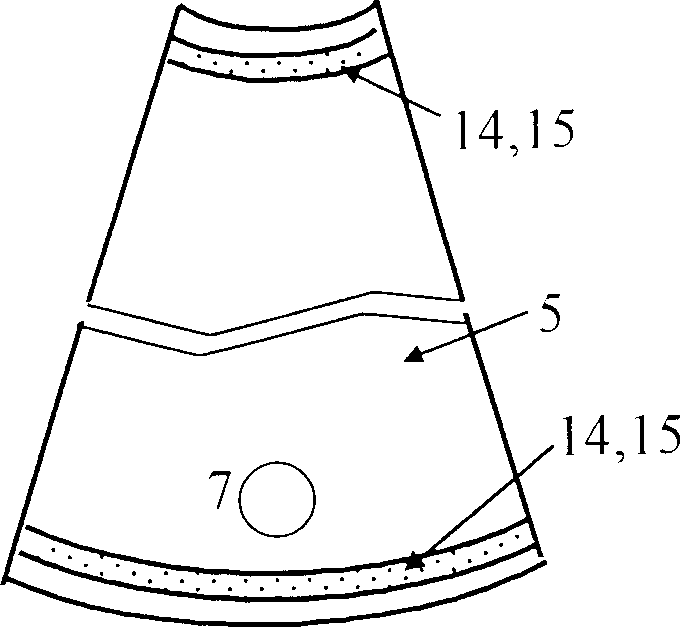

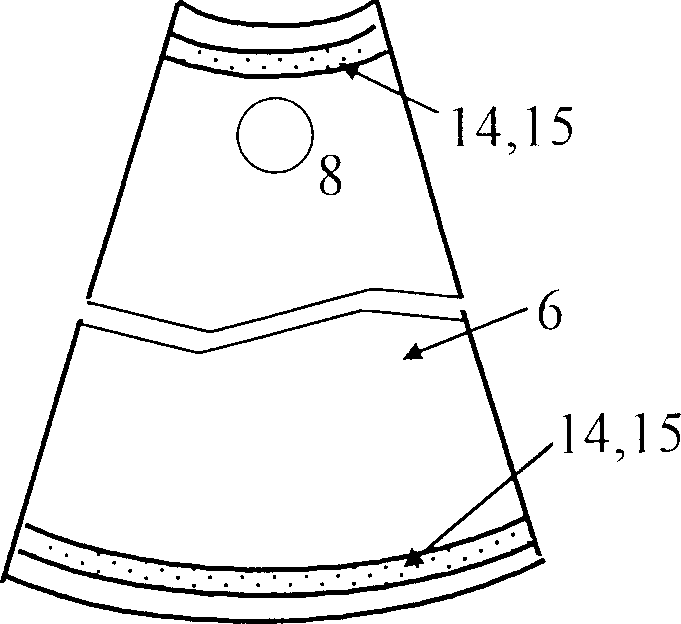

[0019] Such as figure 1 As shown, the middle part of the surface aeration tank 1 is the spiral mixer pump room 2, the outside of the 1 is the sedimentation area 3, and the ring area 4 between 1 and 3 is the surface aeration area, which is also the main area for generating exhaust gas. On the top of the aeration area 4, a top cover composed of standard sealing members 5 and 6 made of engineering plastics is arranged to seal the surface aeration area 4. A vent 7 is arranged on the member 5, and an exhaust pipe 8 is arranged on the member 6, which can be connected with fac...

Embodiment 2

[0027]The water treatment facility used for biochemical aeration reaction in the sewage treatment plant - blast aeration tank, often discharges waste gas containing hydrogen sulfide, benzene, volatile hydrocarbons and so on. The device of the invention is used to seal the aeration tank, collect waste gas and carry out purification treatment.

[0028] Such as Figure 7 As shown, in the aeration tank 17 is a blast aeration area 18, on the inner side wall of the aeration area 18, there is a chute 16; cover to seal the aeration area 18; components 19 and 20 are made of engineering plastics; a vent 21 equipped with a sealing cover is provided on component 19; an exhaust pipe 22 is provided on component 20, which can be discharged through joints and exhaust gas The pipeline is connected with facilities such as induced draft fan, gas purification treatment equipment or exhaust pipe.

[0029] The sealing components on the aeration area 18 are mainly composed of components 19, and on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com