Proton exchange membrane of ordered ion transmission channel and preparation method of proton exchange membrane

A proton exchange membrane and ion transport technology, which is applied in the field of fuel cells, can solve the problems of catalyst poisoning, proton exchange membrane mechanical performance degradation, loss, etc., and achieve the effects of avoiding acid loss, increasing proton conductivity, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

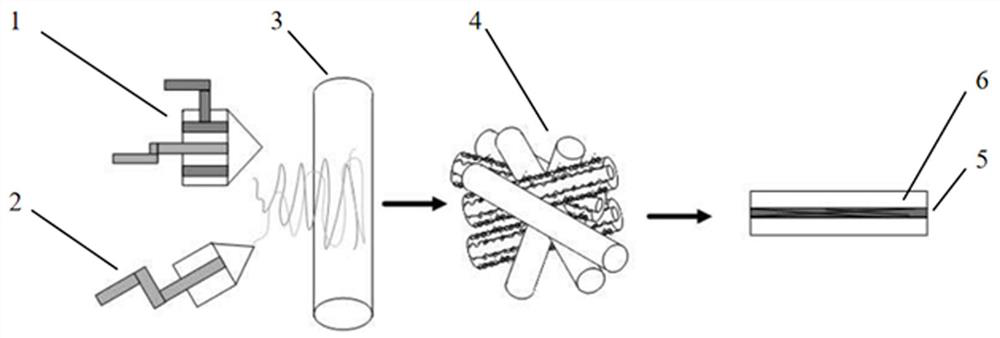

[0030] The present invention provides a preparation method of a proton exchange membrane with an ordered ion transport channel, which mainly comprises the following steps:

[0031] S1: Electrospinning preparation of coaxial multilayer fibers is carried out through a coaxial spinning tube on one side of the spinning receiving roll, while electrospinning preparation of reinforcing fibers is carried out through a single-layer spinning tube. The fibers and the reinforcing fibers are interwoven on the spinning receiving roll, and dried to form a composite fiber porous membrane;

[0032] S2: filling the voids of the composite fiber porous membrane with a pore blocking agent, the pore blocking agent comprising a perfluorosulfonic acid resin solution, reinforcing fibers and a quenching agent;

[0033] S3: hot pressing and flattening to obtain a proton exchange membrane with ordered ion transport channels.

[0034] In step S1, the coaxial spinning tube and the single-layer spinning tu...

Embodiment 1

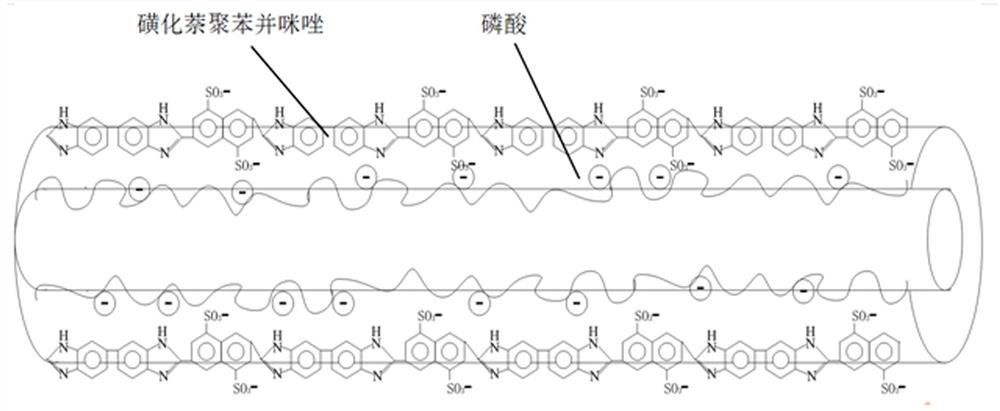

[0037] like figure 1 As shown, the coaxial spin tube 1 has a shell channel and an inner channel arranged coaxially. The shell layer channel is supplied with sulfonated naphthalene polybenzimidazole solution as the shell layer spinning solution, and the inner layer channel is supplied with phosphoric acid solution as the inner layer spinning solution. The single-layer spinning solution in the single-layer spinning tube 2 consists of a perfluorosulfonic acid resin solution. By placing the coaxial spinning tube 1 and the single-layer spinning tube 2 on the same side of the spinning take-up roll 3 for simultaneous co-spinning, the coaxial multi-layer fiber prepared by the coaxial spinning tube 1 and the single-layer spinning The reinforcing fibers prepared by the tube 2 are interwoven into a network structure, and the composite fiber porous membrane is obtained after drying and removing the solvent.

[0038] The ion channel of the coaxial multilayer fiber obtained by the above m...

Embodiment 2

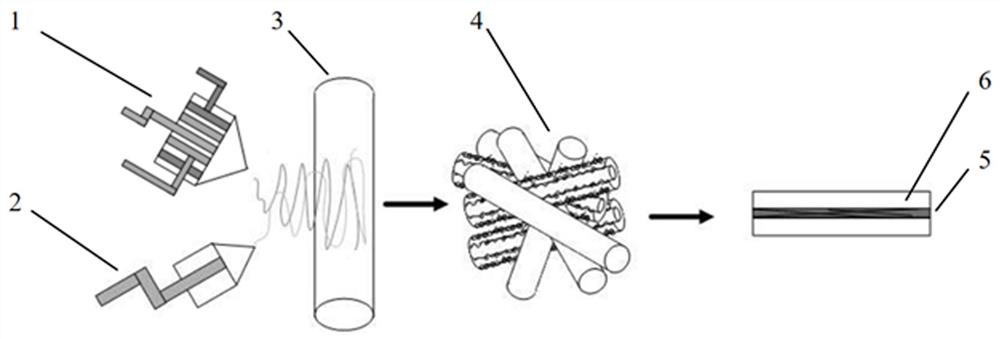

[0042] This embodiment is similar to Embodiment 1, in that the coaxial spinning tube has a shell channel and an inner channel arranged coaxially. Phosphorylated benzimidazole solution was used as the shell layer spinning solution in the shell layer channel, and perfluorosulfonic acid resin solution was used as the inner layer spinning solution in the inner layer channel. The single-layer spinning solution in the single-layer spinning tube consists of a perfluorosulfonic acid resin solution.

[0043] After the composite fiber porous membrane is obtained, the voids of the composite fiber porous membrane are filled by screen printing using a pore blocking agent. The pore blocking agent includes a perfluorosulfonic acid resin solution, reinforcing fibers and a quenching agent; specifically, sulfonated polyether ether ketone is used as the reinforcing fiber, and manganese oxide is used as the quenching agent.

[0044] Finally, the proton exchange membrane with the ordered ion tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com