Coated tempered glass and production process thereof

A tempered glass and production process technology, applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of uneven coverage of coating solution, low attraction, affecting the coating effect of tempered glass, etc., so as to improve the adhesion effect , Improve the effect, reduce the effect of impact and material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

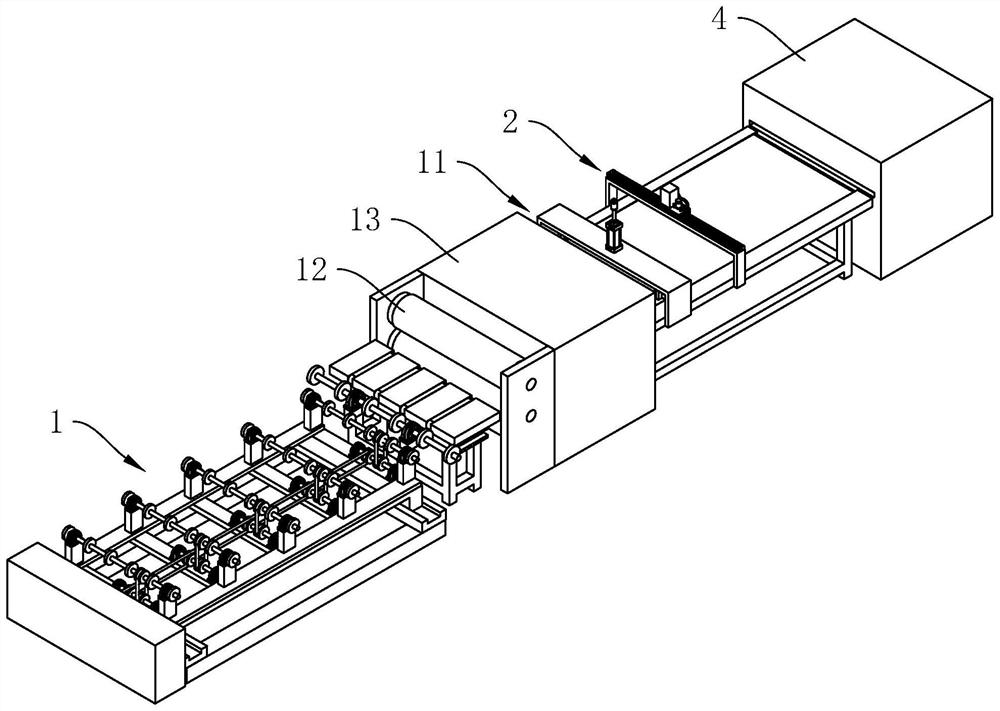

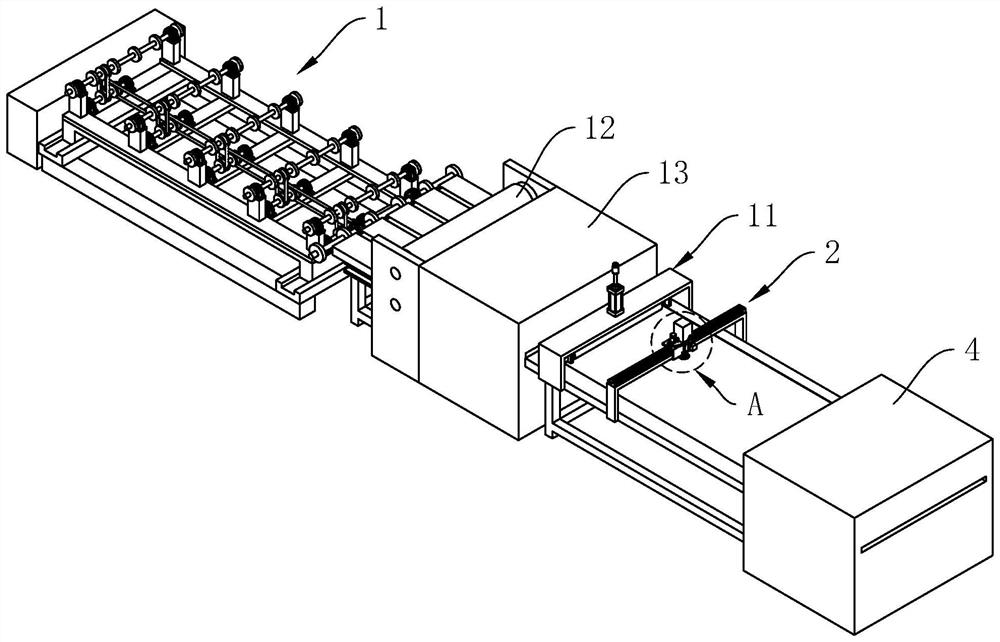

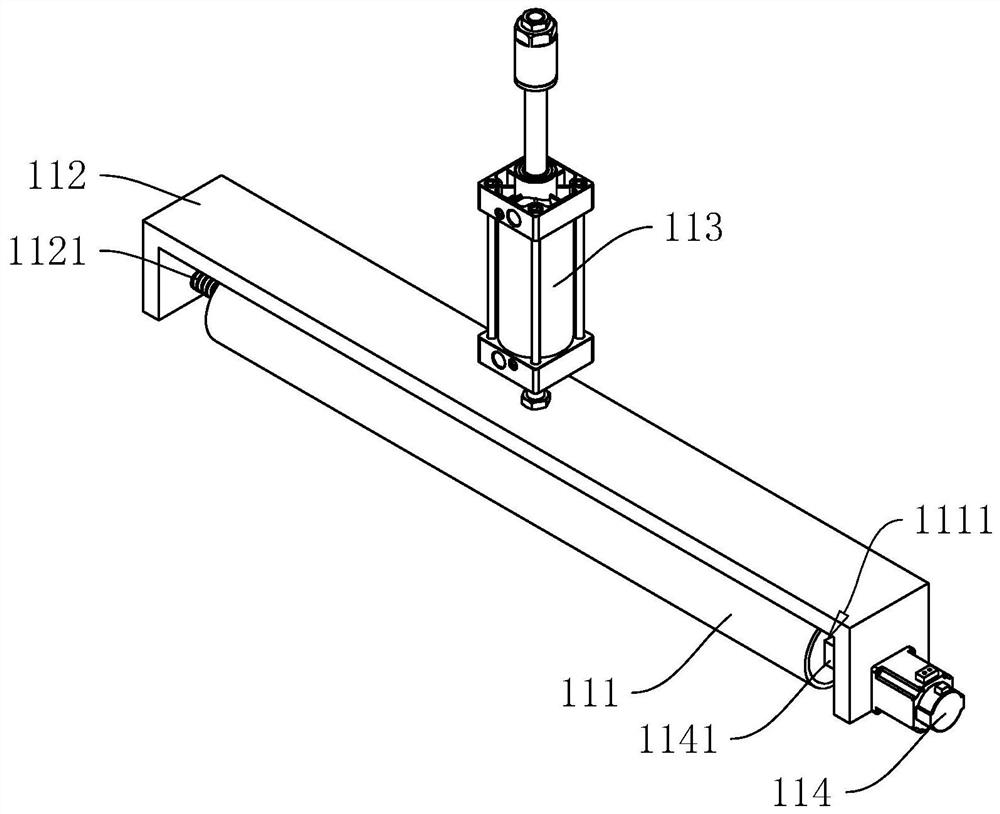

[0042] Attached to the following Figure 1-6 This application will be described in further detail.

[0043] On the one hand, the embodiments of the present application disclose a production process of coated tempered glass.

[0044] refer to figure 1 and figure 2 , The production process of coated tempered glass includes the following steps:

[0045] Step 1: Glass original sheet cleaning: place the glass original sheet on the conveying device 1, and clean and dry the glass original sheet during the conveying process;

[0046] Step 2: Rub the original glass sheet: rub the upper surface of the original glass sheet with silk to make the upper surface of the original glass sheet with positive ions;

[0047] Step 3: Coating liquid spraying: spray the coating liquid through the spraying device 2, and then generate negative ions through the negative ion generator 3, and the negative ions are combined with the atomized coating liquid, so that the atomized coating liquid can quickly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com