Unsaturated polyester resin accelerant as well as preparation method and application thereof

A polyester resin, unsaturated technology, used in the field of adhesives for the preparation of artificial stone, can solve the problems of finished products cracking and scrapping, unable to remove in time, unstable quality, etc., and achieves high production costs, shortened gelation time, and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

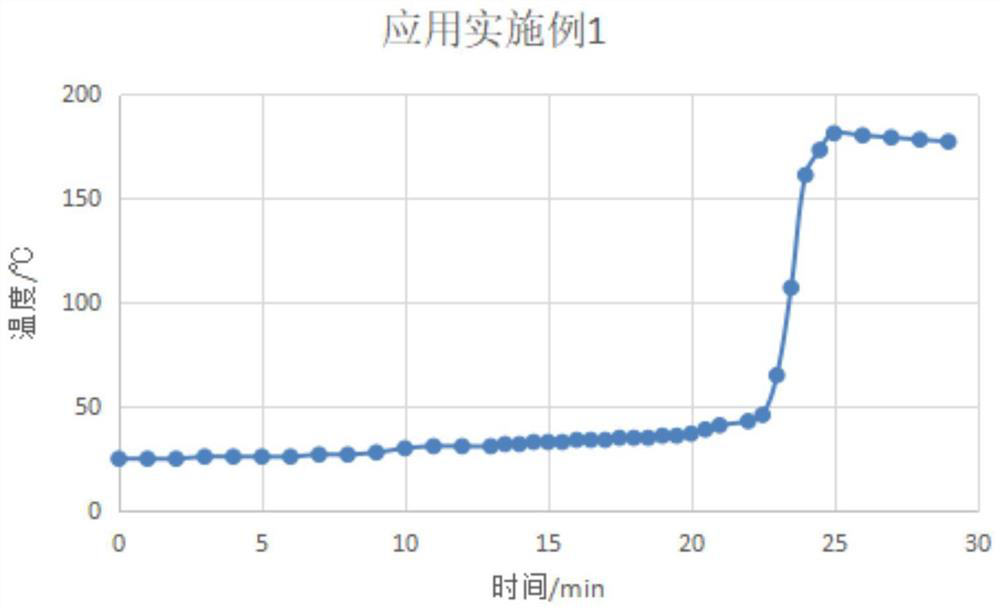

Embodiment 1

[0039] The unsaturated polyester resin accelerator (hereinafter referred to as copper naphthenate accelerator) of this embodiment is composed of the following raw materials: methanol 82.0 kg, copper naphthenate 17.3 kg, and cobalt isooctanoate 0.7 kg.

[0040] Its preparation method comprises the following steps:

[0041] Pour methanol, copper naphthenate, and cobalt isooctanoate into a stirring tank, and stir at a rotational speed of about 100 r / min for 30 minutes to obtain the result.

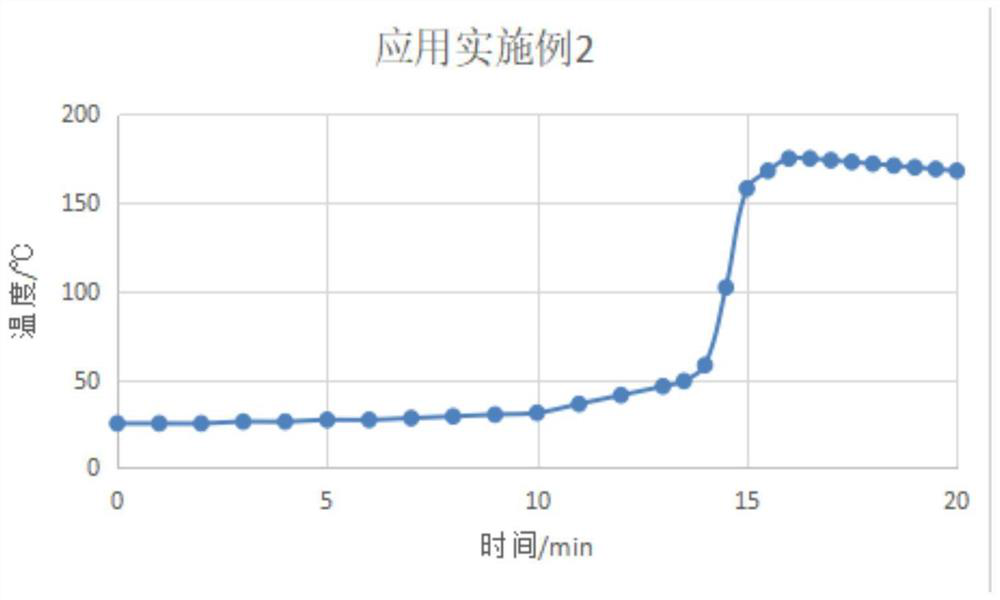

Embodiment 2

[0043] The unsaturated polyester resin accelerator (hereinafter referred to as copper naphthenate accelerator) of this embodiment is composed of the following raw materials: methanol 87.0kg, copper naphthenate 12.3kg, and cobalt isooctanoate 0.7kg.

[0044] Its preparation method comprises the following steps:

[0045] Pour methanol, copper naphthenate, and cobalt isooctanoate into a stirring tank, and stir at a rotational speed of about 100 r / min for 30 minutes to obtain the result.

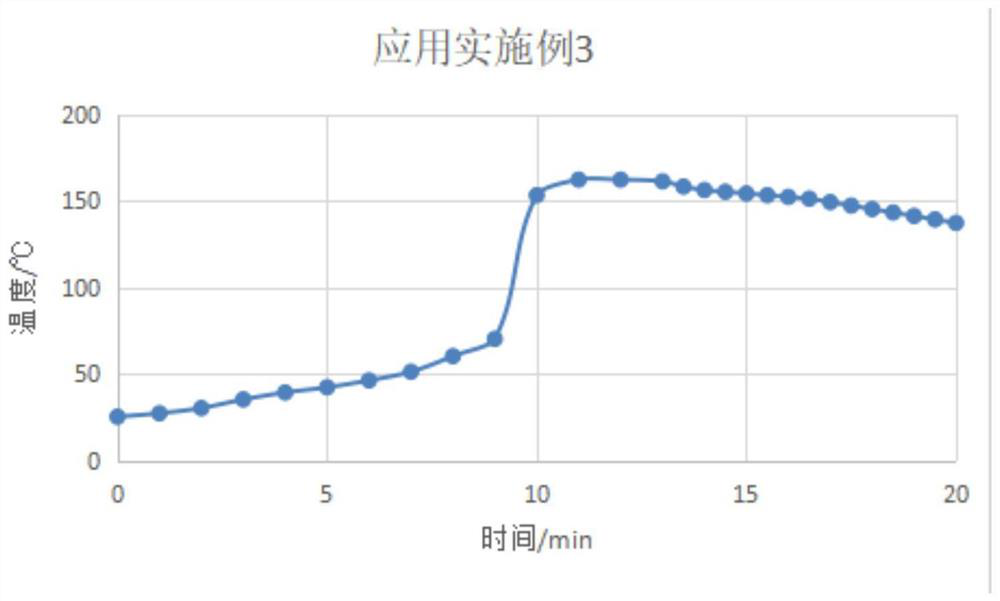

Embodiment 3

[0047] The unsaturated polyester resin accelerator (hereinafter referred to as copper naphthenate accelerator) of this embodiment is composed of the following raw materials: methanol 86.7kg, copper naphthenate 12.3kg, and cobalt isooctanoate 1.0kg.

[0048] Its preparation method comprises the following steps:

[0049] Pour methanol, copper naphthenate and cobalt isooctanoate into a stirring tank, and stir at a rotational speed of about 100 r / min for 30 minutes to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com