High-toughness free-cutting non-quenched and tempered round steel and manufacturing method thereof

A manufacturing method and non-quenching and tempering technology, applied in the field of steel and its manufacturing, can solve the problems of insufficient toughness and excessive hardness, and achieve the effects of loose process window, easy cutting, reasonable chemical composition and related process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

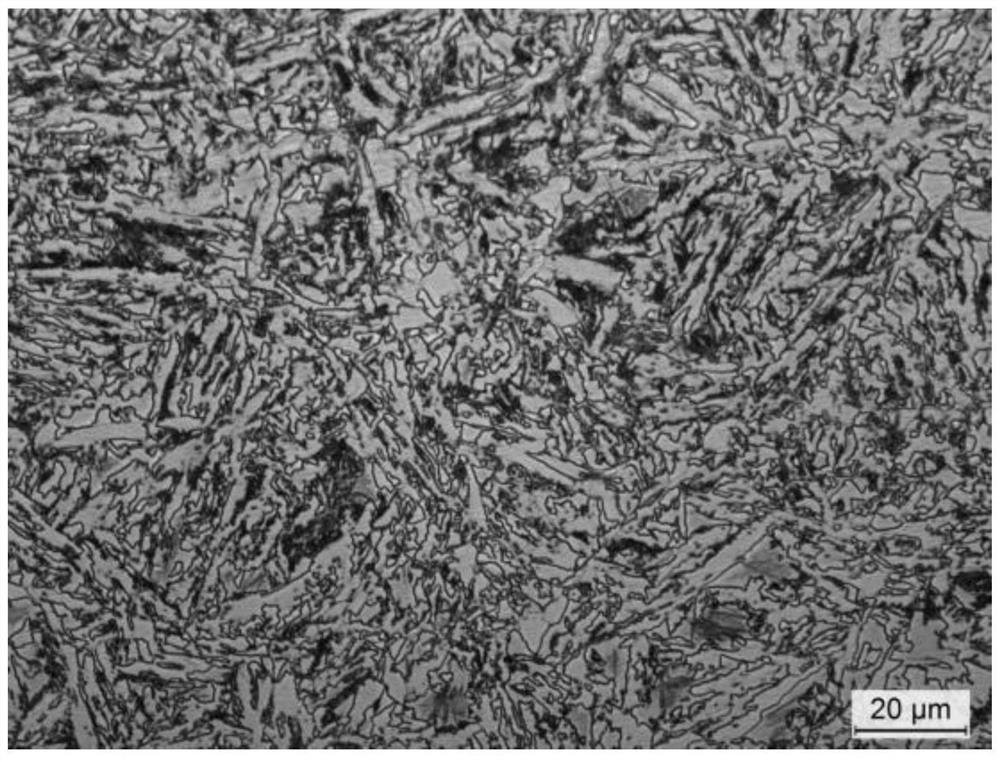

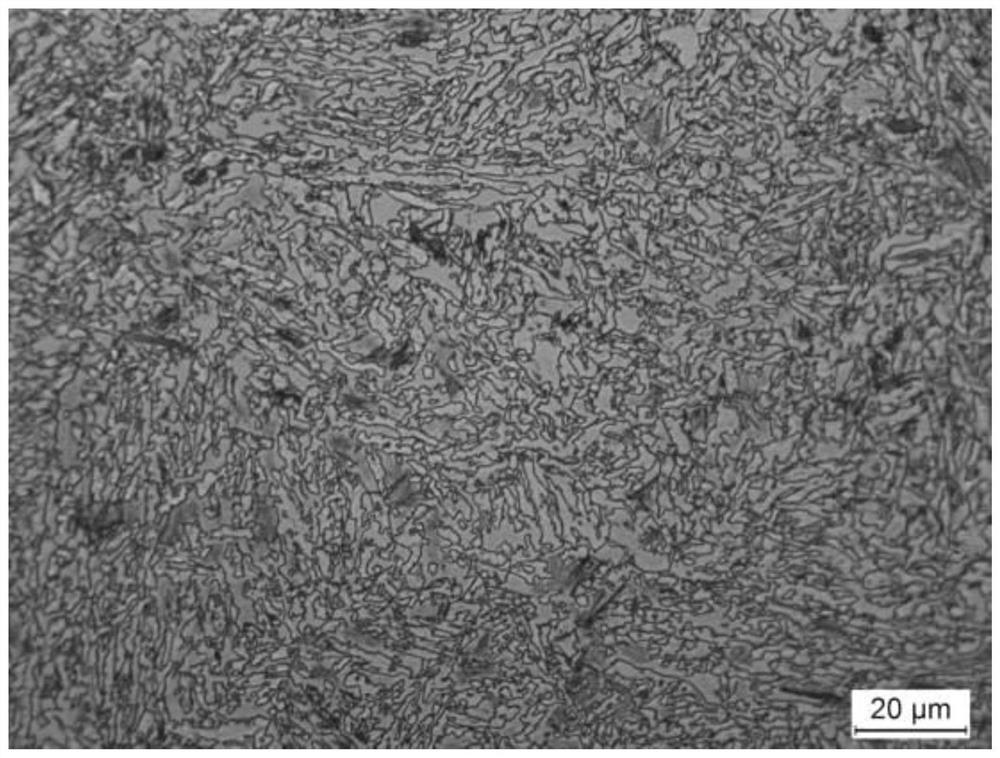

Examples

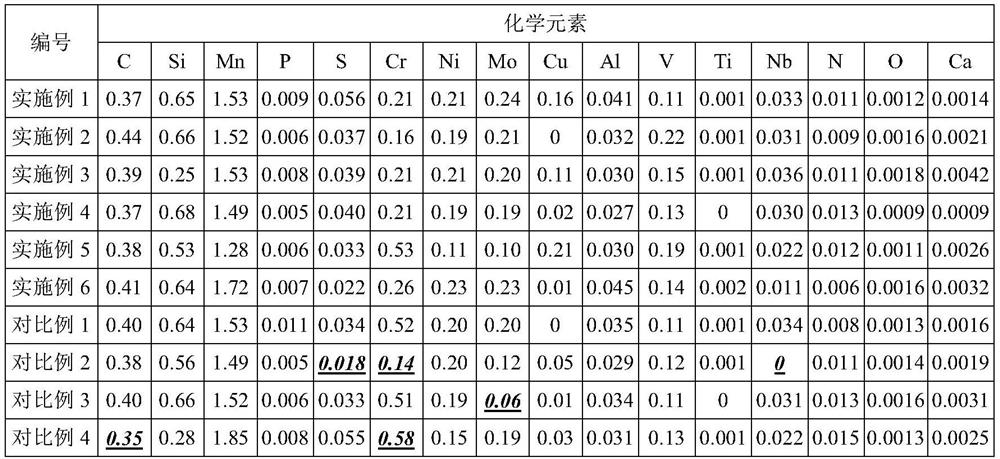

Embodiment 1-6 and comparative example 1-4

[0063] The high-strength, tough, free-cutting, non-quenched and tempered round steels of Examples 1-6 are obtained by the following steps:

[0064] (1) Smelting and casting are carried out according to the chemical compositions shown in the following Tables 1-1 and 1-2: 50kg vacuum induction furnace or 150kg vacuum induction furnace can be used for smelting, or electric furnace smelting + out-of-furnace refining can be used for smelting + Smelting by vacuum degassing.

[0065] (2) Heating: control the heating temperature to be 1050~1250℃, and the holding time to be 3~24h.

[0066] (3) Forging or rolling: control the final rolling temperature or the final forging temperature ≥800℃; cool after rolling or forging, control the cooling rate ≤1.5℃ / s, and the cooling method can be air cooling or air cooling.

[0067] (4) Finishing, such as peeling.

[0068] It should be noted that, in the above-mentioned step (3), when forging is performed, it can be directly forged to the final prod...

Embodiment 1

[0070] Example 1: Smelting was carried out on a 50kg vacuum induction furnace according to the chemical compositions shown in Table 1-1 and Table 1-2 below. The molten steel is cast into ingots, heated and forged to open billets. The heating temperature is 1050 °C, and the forging is carried out after holding for 3 hours.

Embodiment 2

[0071] Example 2: Smelting was carried out on a 150kg vacuum induction furnace according to the chemical compositions shown in Table 1-1 and Table 1-2 below. The molten steel is cast into ingots, heated and forged to open billets, the heating temperature is 1100 ° C, and the forging is carried out after holding for 4 hours. The bar material is then air-cooled, and then turned and peeled to Φ90mm after air-cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com