High-temperature decomposition device and method for industrial tail gas containing N2O

A technology for pyrolysis and industrial tail gas, applied in the direction of separation methods, combustion methods, chemical instruments and methods, etc., can solve the problems of reducing denitrification agent, catalyst use efficiency, increasing the processing burden of catalytic decomposition system, reactor and catalyst damage, etc. , to reduce the amount of denitrification treatment, prevent excessive temperature fluctuations, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

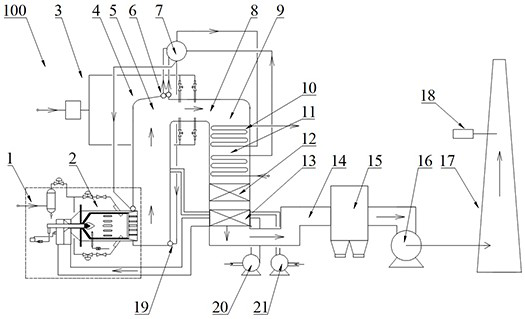

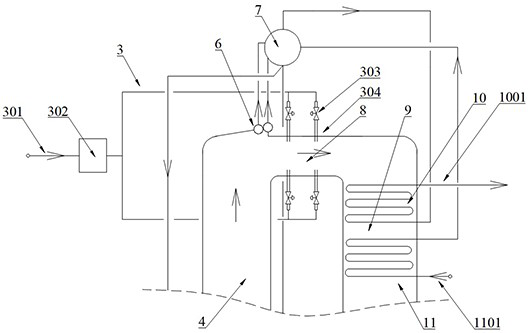

[0054] Specific examples are as follows, such as figure 1 shown: one for N 2 O high-temperature decomposition device of industrial tail gas, including raw gas intake system 1, high-temperature decomposition furnace 2, kiln 4, denitration agent distribution system 3, and denitration catalyst packing layer 12;

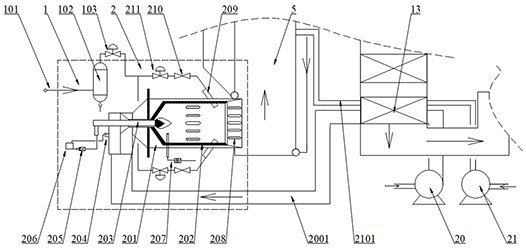

[0055] The feed gas intake system 1 includes a feed gas source 101 and a gas-liquid separator 102 communicating with the feed gas source. A feed gas control valve 103 is provided at the gas outlet end of the gas-liquid separator 102, and the feed gas control valve can control the entry of feed gas into The speed and air intake of the pyrolysis furnace; the gas-liquid separator can remove the nitrogen-containing 2 O Nitric acid or mist droplets in industrial tail gas, realize the purification and drying of raw material gas;

[0056] Among them, the inlet end of the pyrolysis furnace 2 is communicated with the raw material gas intake system 1, and the dried raw material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com