Device and method for measuring diameter of circular tube product by cross method

A product, the technology of round tubes, which is applied in the field of measuring devices for the size of round tube products, can solve the problems of low efficiency of round tube products, achieve the effects of improved efficiency, good adaptability, and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

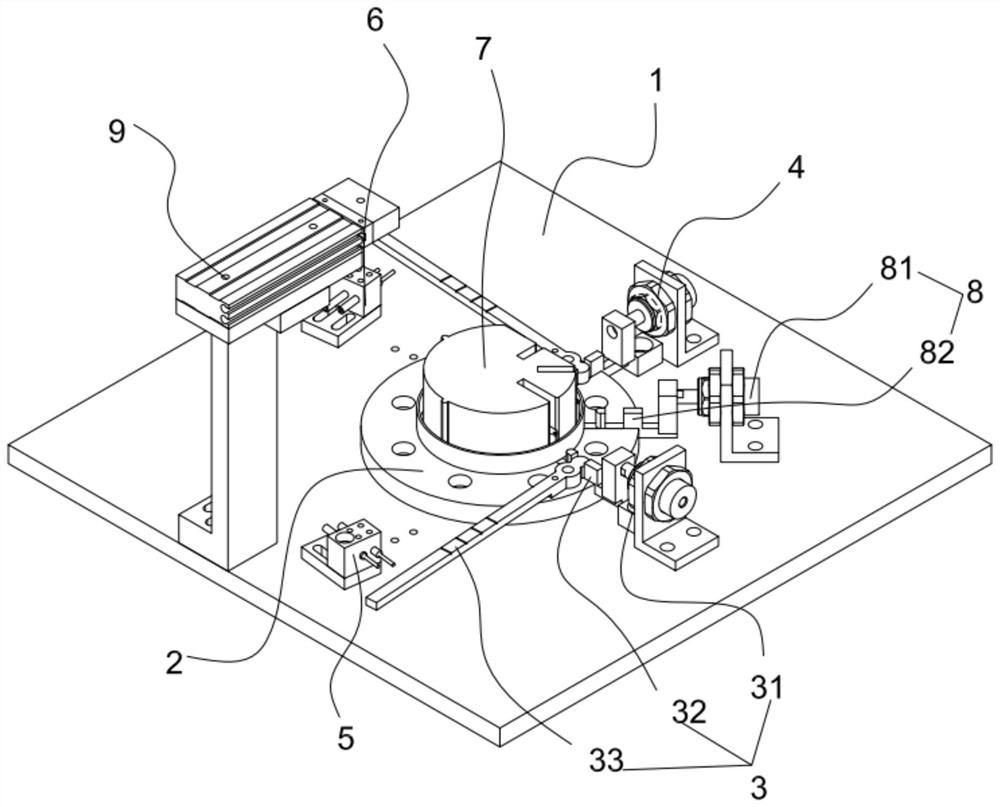

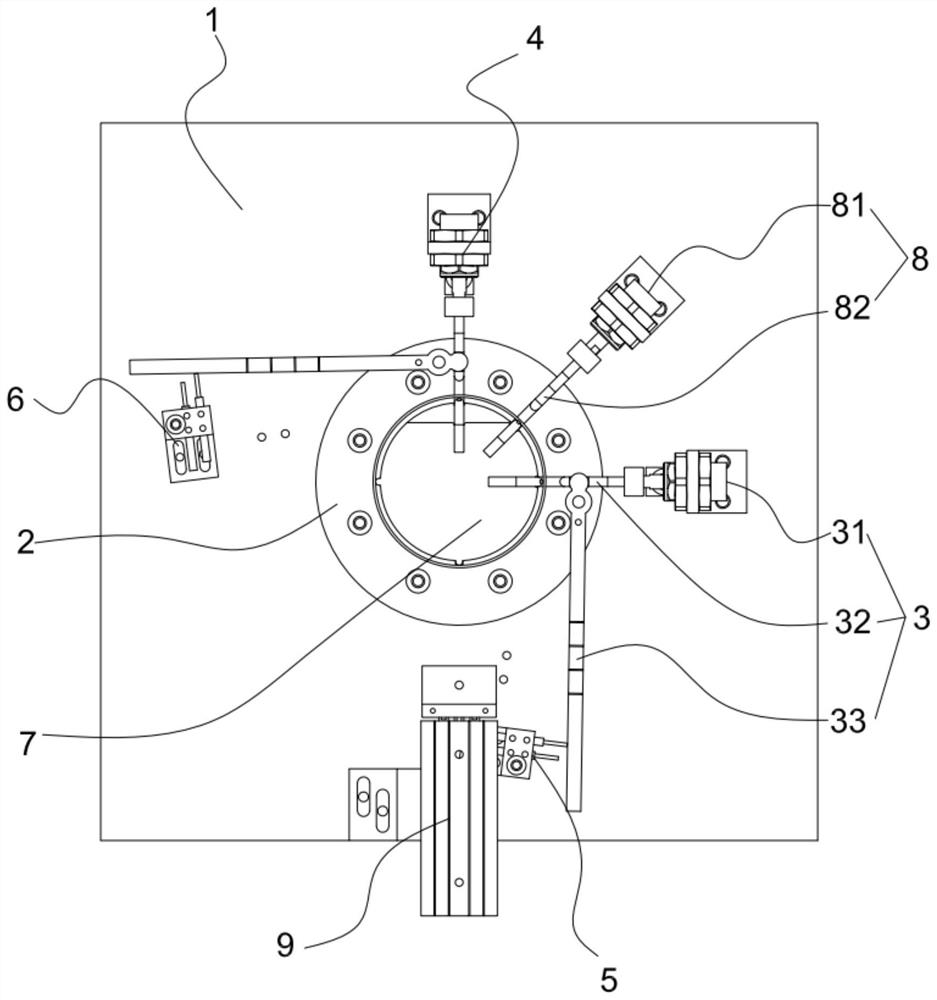

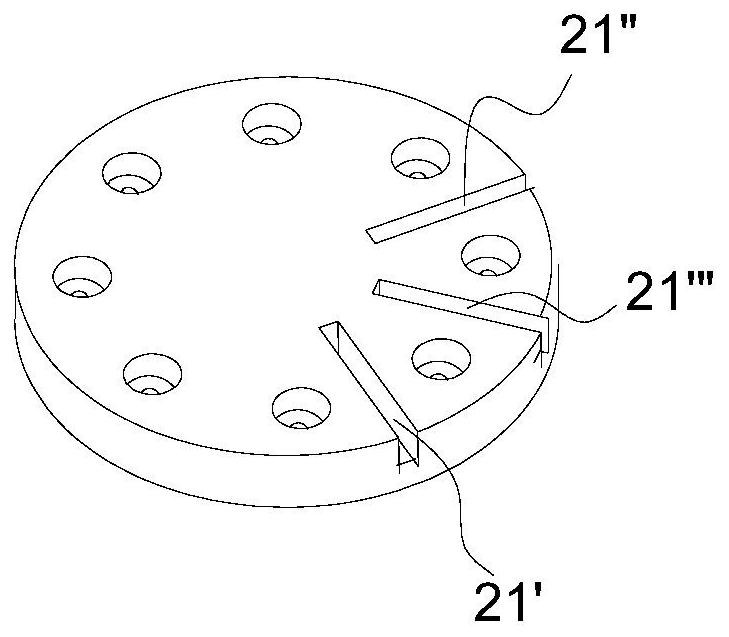

[0070] like figure 1 , figure 2 As shown in the figure, the device for measuring the diameter of a round tube product by the cross method includes a workbench 1, a base 2, two measuring components, two tolerance probe components, a positioning column 7, and a positioning component 8; the two measuring components have the same structure and are located in The horizontal position and the vertical position, the measuring component located in the horizontal position is the horizontal measuring component 3, the measuring component located in the vertical position is the vertical measuring component 4, the two are vertically distributed to each other, the horizontal measuring component is used to measure the inner diameter in the horizontal direction, and the vertical measuring component 4 For measuring the inner diameter in the vertical direction, the two tolerance probe assemblies are the horizontal tolerance probe assembly 5 and the vertical tolerance probe assembly 6. The horiz...

Embodiment 2

[0086] This embodiment provides a method for measuring the inner diameter of a round tube product by the cross method in the above-mentioned first embodiment, which includes the following steps:

[0087] Step S1: debug the device;

[0088] Specifically, if the inner diameter of a product is φ81±0.3mm, the upper limit size is φ81.3mm, and the lower limit size is φ80.7mm. Before debugging the equipment, process the lower and upper tolerance gauges with inner diameters of φ80.70mm and φ81.3mm.

[0089] Put the 80.70mm inner diameter lower tolerance check tool into the positioning column 7, the positioning cylinder 81 moves, and drives the positioning slide rod 82 to move away from the center of the circle, until the positioning slider 821 contacts the inner wall of the inner diameter lower tolerance check tool, stops the movement, and the positioning slide The block 821 and the limiting rib 71 form three support points to clamp the lower tolerance check tool; the horizontal meas...

Embodiment 3

[0108] This embodiment adopts the above-mentioned method of measuring the outer diameter of the round tube product by the cross method. When the above-mentioned device is used to measure the outer diameter, the difference from the device in the first embodiment is that the horizontal tolerance probe assembly 5 is located at the swing rod 33 of the horizontal measurement assembly 3. On the right side, the upper tolerance probe 53 is located below the upper tolerance probe 53, and the protruding length of the upper tolerance probe 53 is greater than the length of the upper tolerance probe 53; the vertical tolerance probe assembly 6 is located on the swing rod of the horizontal measurement assembly 3 33 on the upper side.

[0109] The steps of the method for measuring the outer diameter of the round tube product by the cross method are as follows with reference to Embodiment 2:

[0110] Step S1: debug the device;

[0111] Specifically, if the outer diameter of a product is φ100±...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com