Argo buoy and ocean acoustics and environmental parameter collaborative observation method based on Argo buoy

A buoy and acoustic technology, applied in the direction of buoys, ultrasonic/acoustic/infrasonic transmission systems, special-purpose ships, etc., can solve the limitations of Argo buoy data observation quality and application fields, cannot meet the needs of ocean acoustics and environmental parameter observation, does not have Underwater interactive communication function and other issues, to achieve the effect of improving the quality of data measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

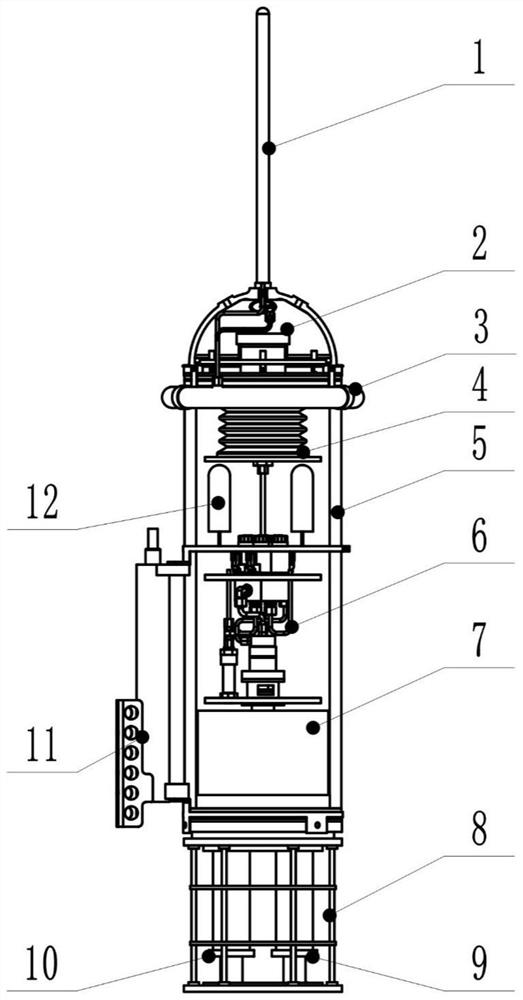

[0063] An Argo buoy such as Figure 1-2 As mentioned above, it includes a pressure-resistant casing 5, which is used to withstand external water pressure to ensure that the internal parts of the Argo buoy are isolated from seawater, and a communication antenna 1 is fixed on the outside of the pressure-resistant casing 5 for transmitting data with satellites. , and obtain positioning information through satellites; the outside of the pressure-resistant shell 5 is also provided with a buoyancy oil bag 3 and a thermo-salinity instrument 11, and the thermo-salinity instrument 11 is used to collect the temperature, salinity and depth environmental parameter information of the ocean water body; A control module 2, an oil storage bag 4, a hydraulic buoyancy adjustment device 6 and a battery 7 are arranged inside the pressure housing 5. The control module 2 is used to send control signals to the hydraulic buoyancy adjustment device 6 and the acoustic transmitter 10, and to process the ...

Embodiment 2

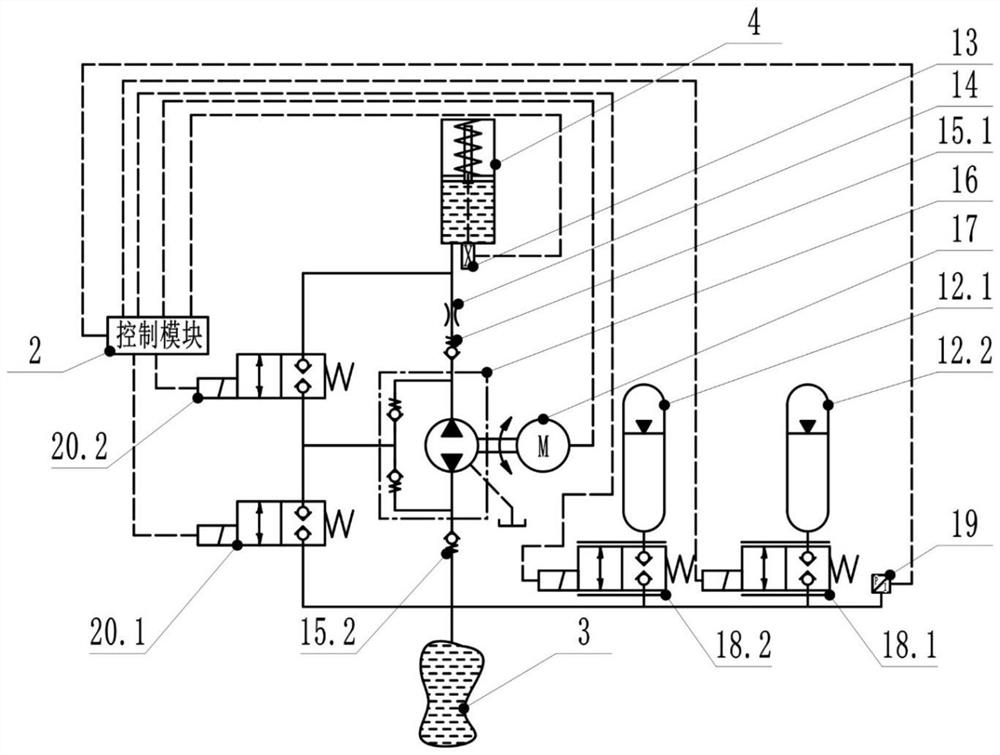

[0068] An Argo buoy, as described in Embodiment 1, the difference is that the hydraulic buoyancy adjusting device 6 includes a linear displacement sensor 13, a damper 14, a one-way valve A15.1, a one-way valve B15.2, a two-way gear pump 16. Electric motor 17, pressure transmitter 19, 2 / 2-way proportional valve A 18.1, 2 / 2-way proportional valve B18.2, 2 / 2-way solenoid valve A 20.1, 2 / 2-way solenoid valve B20.2 and hydraulic Accumulator, hydraulic accumulator includes hydraulic accumulator A 12.2 and hydraulic accumulator B12.1;

[0069] The linear displacement sensor 13 is installed inside the oil storage bag 4 to measure the telescopic displacement Δx of the oil storage bag 4;

[0070] The oil storage bag 4 is connected to the two-way gear pump 16 through the damper 14 and the one-way valve A 15.1. The damper 14 is installed between the oil storage bag 4 and the one-way valve A 15.1 to prevent the oil inlet and outlet of the two-way gear pump 16. When there is a large pressu...

Embodiment 3

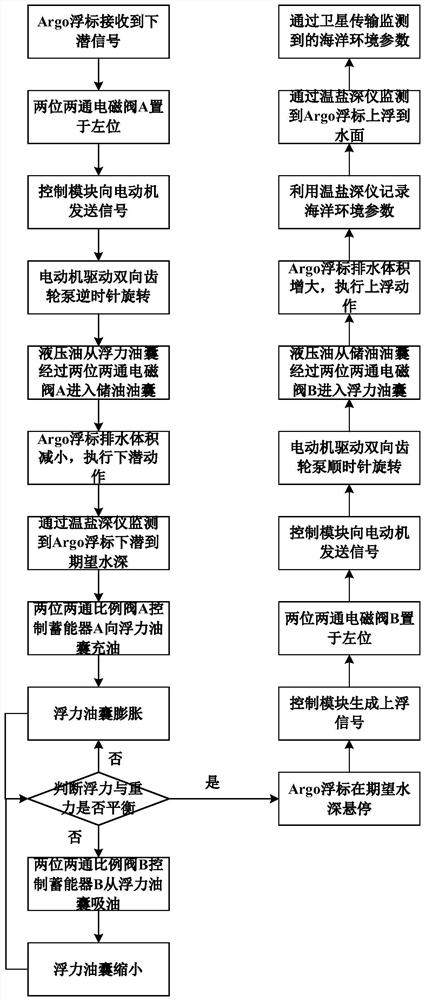

[0078] like image 3 , the working process of an Argo buoy is:

[0079] The Argo buoy receives the dive signal sent by the satellite, the control module 2 sets the two-position two-way solenoid valve A 20.1 to the left position, and sends a signal to the motor 17, so that the motor 17 drives the two-way gear pump 16 to rotate counterclockwise, and the hydraulic oil The buoyancy oil bag 3 enters the oil storage bag through the two-position two-way solenoid valve A 20.1 and the two-way gear pump 16, the volume of the buoyancy oil bag 3 is reduced, the drainage volume of the Argo buoy is reduced, and the diving action is performed;

[0080] The Argo buoy is monitored by the thermometer 11 to dive to the desired water depth, and the two-position proportional valve A 18.1 controls the hydraulic accumulator A 12.2 to fill the buoyancy oil bag 3 with oil, so as to expand the buoyancy oil bag 3, and use the temperature and salt depth. Instrument 11 monitors the ascending and descendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com