Piezoelectric pressure sensor

A pressure sensor, piezoelectric technology, applied in the direction of fluid pressure measurement using piezoelectric devices, fluid pressure measurement through electromagnetic components, and measurement of the property and force of piezoelectric devices. Fragmentation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

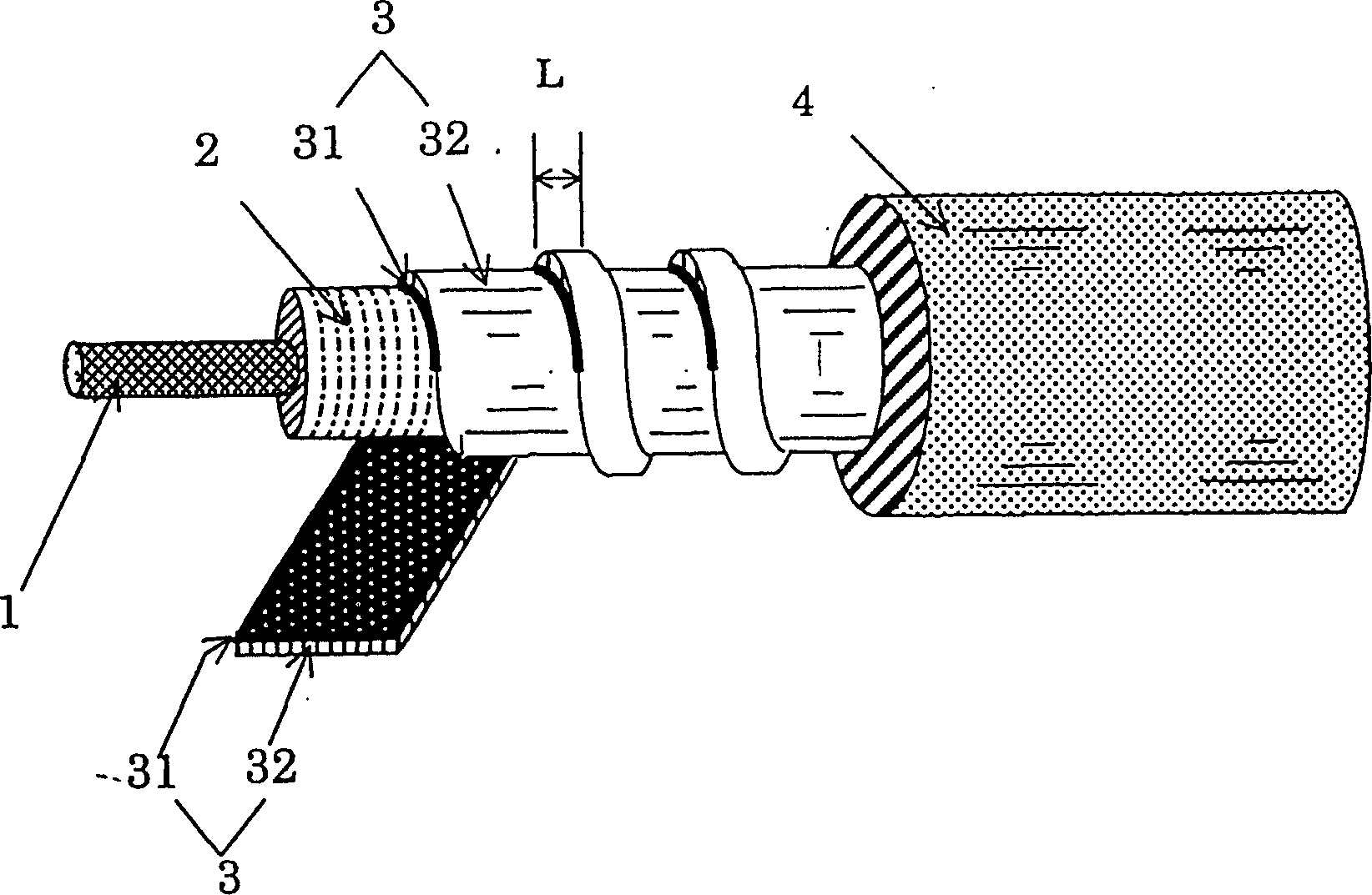

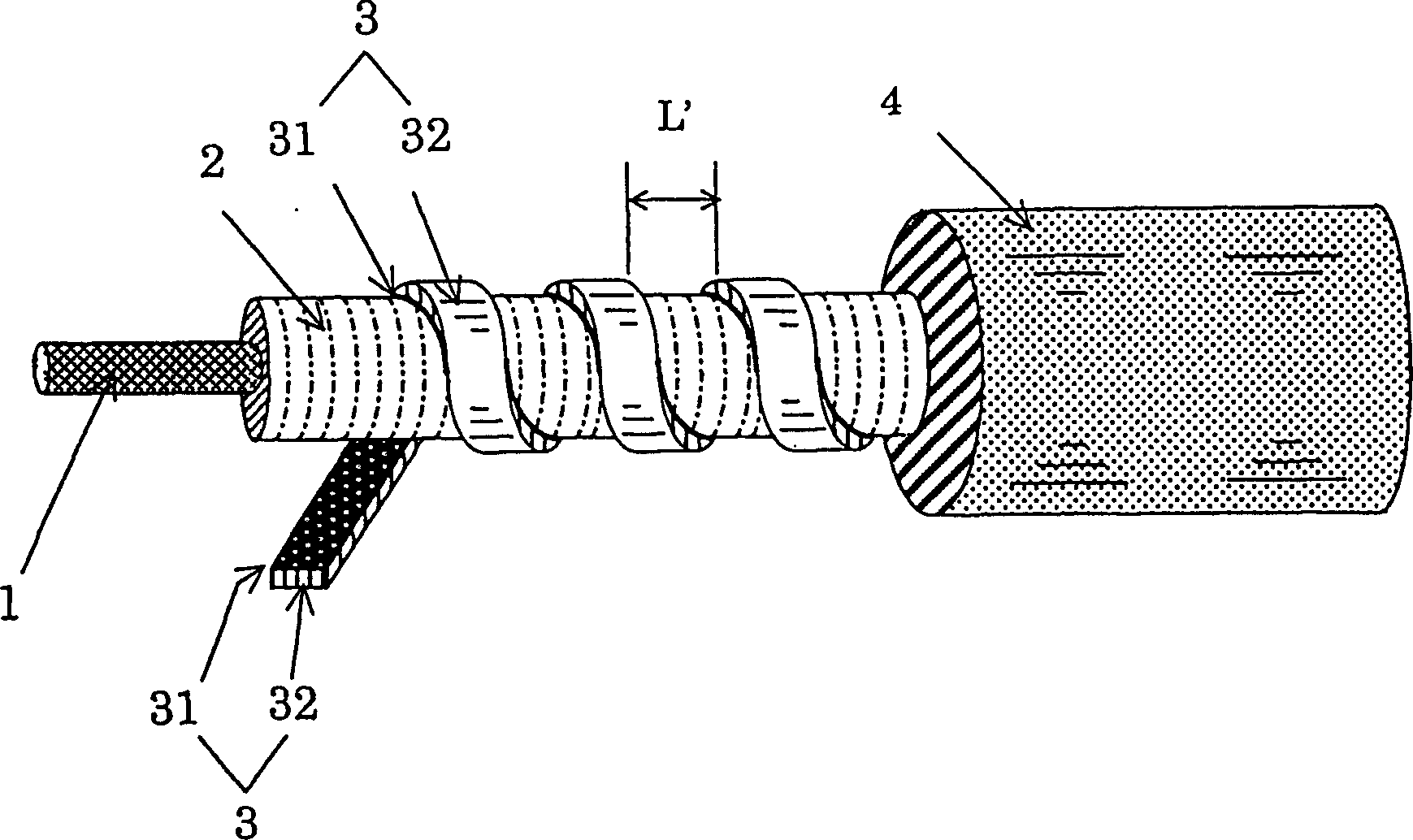

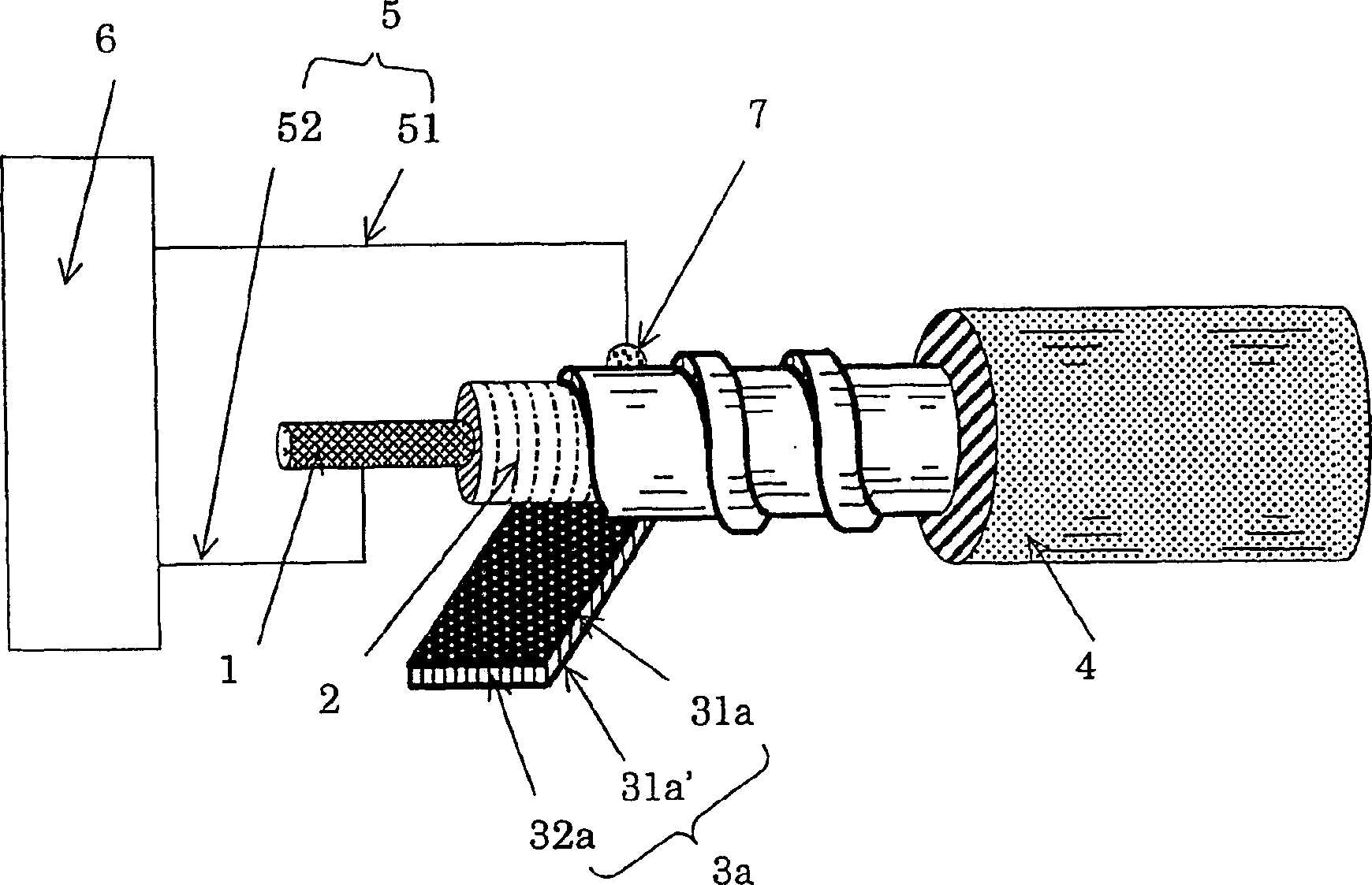

[0046] figure 1 For the best structure of the piezoelectric cable of the present invention, it includes: an inner conductor (1) made of a single-strand metal wire or a small multi-strand cascaded steel wire; Electrical composite layer (2), the composite layer (2) contains amorphous chlorinated polyethylene (a-CPE), crystalline chlorinated polyethylene (c-CPE) and piezoelectric ceramic powder; The outer conductor (3) formed by the metal film (31) on (32), the metal film (31) is in contact with the piezoelectric composite layer (2) but not in contact with the inner conductor (1); A protective sheath (4) made of insulating elastic material wrapped around the outer conductor (3).

[0047] The piezoelectric cable of the present invention is produced according to the following process procedures. First, lead titanate-lead zirconate (PbTiO 3 -PbZrO 3 ) powder is evenly attached to the CPE substrate, and then the rolled composite plate containing ceramic powder is cut into small p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com