Control system and method for port winter dust removal automatic water feeding butt joint device

A technology of automatic water filling and docking device, which is applied in the direction of separation method, chemical instrument and method, conveyor control device, etc., which can solve the problems of time-consuming reliability, waste of time for stacker shifting and water filling, and high labor intensity of operation and other issues to achieve the effect of improving work efficiency, saving labor costs, and reducing manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described in detail below through specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

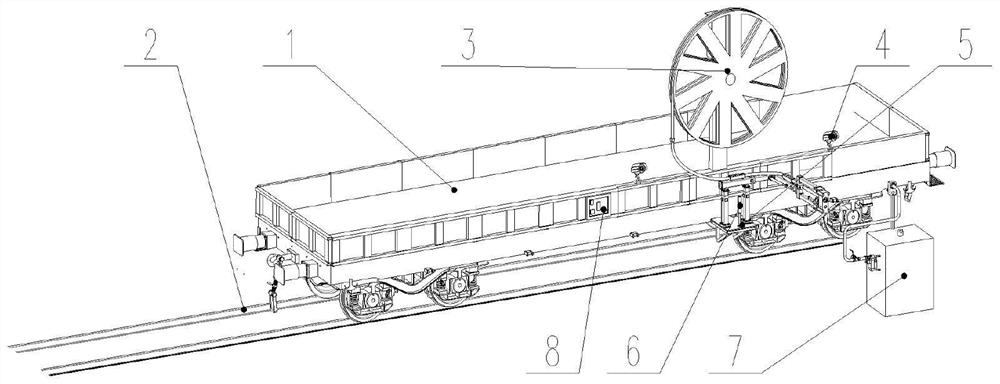

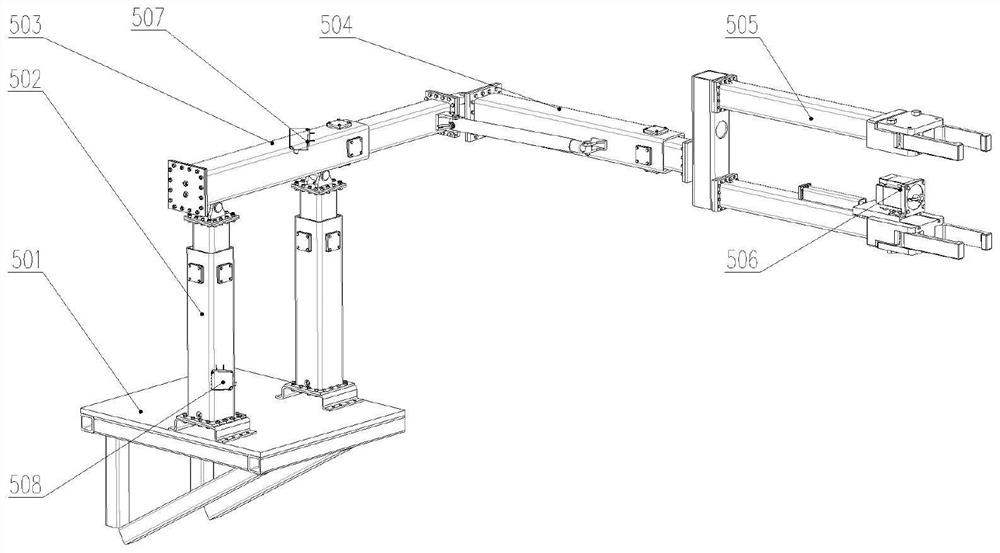

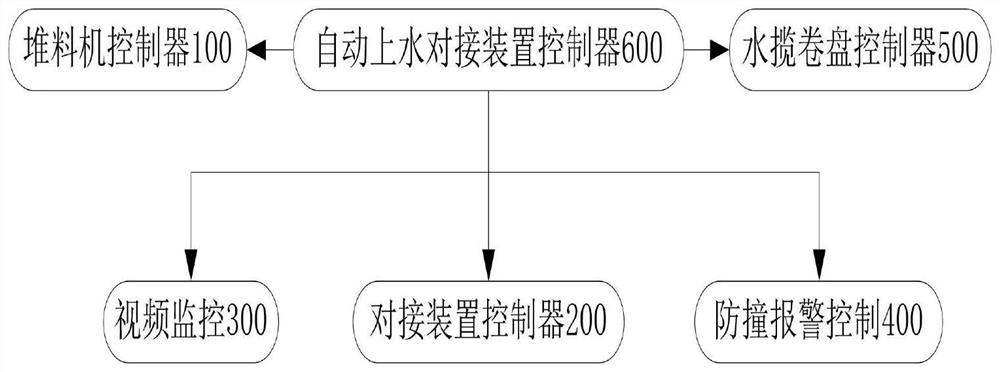

[0064] like figure 1 As shown in the figure, the port winter dust removal automatic docking and docking device in the embodiment of the present invention includes a stacker 1, a steel rail 2, a water cable reel 3, a video monitor 4, an automatic docking mechanism 5, an anti-collision alarm device 6, and a spray gun. Site 7 and electric control box 8;

[0065] Among them, the stacker 1 stands on the steel rail, and runs reciprocatingly along the rail under the traction of the power device; the water cable reel 3 is installed on the end surface of the side plate of the stacker 1, and the water cable reel is made by welding technology. 3 is fixed on the stacker 1, and the stacker 1 drives the water cable reel 3 to reciprocate. During the operation, the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com