Glass processing equipment and glass assembly line

A technology for processing equipment and glass, applied in glass manufacturing equipment, glass rolling, glass forming, etc., can solve problems such as increased labor burden on workers, surface collision of rolling rolls, uneven glass surface, etc., to reduce labor burden, prevent Damaged, reduced frequency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

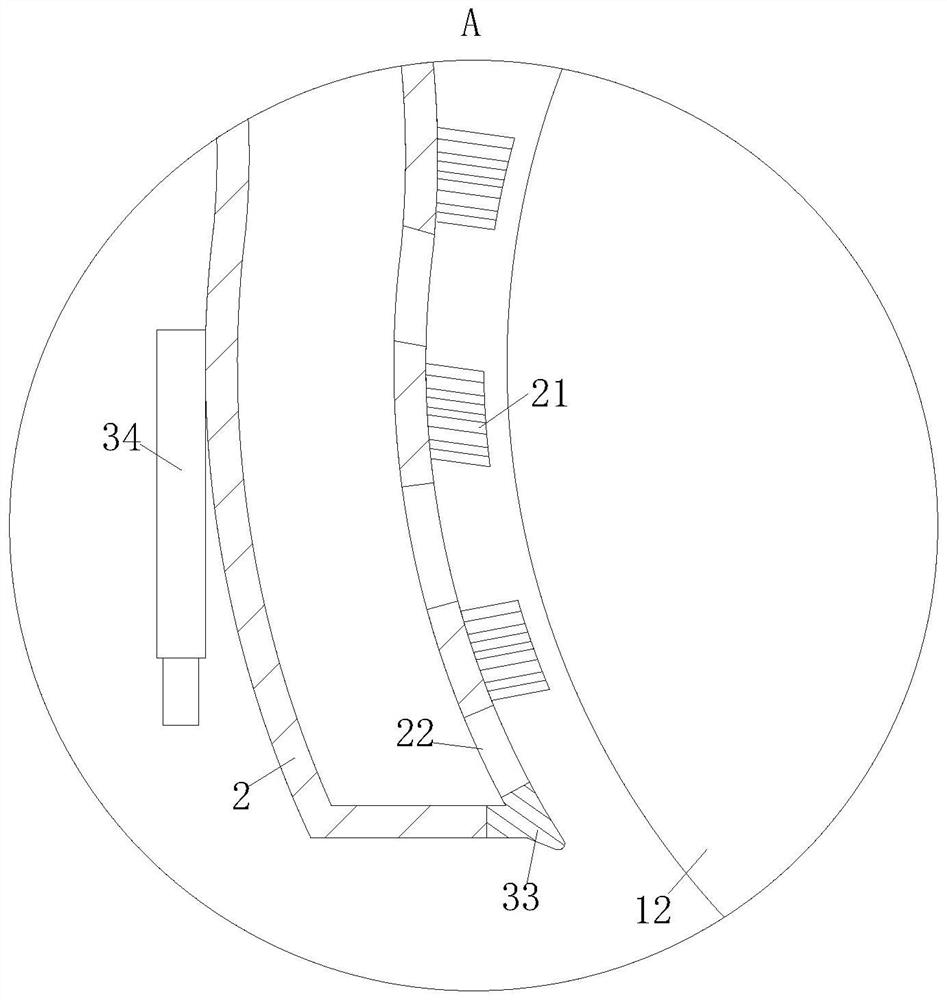

[0044] As an embodiment of the present invention, the surface shape of one end of the dust suction pipe 2 close to the calendering roller 12 is set as an arc;

[0045] When working, the outer surface shape of one end of the suction pipe 2 close to the calendering roller 12 is set to be arc-shaped, so that the sand bristle block 21 on the arc surface is more suitable for the surface of the calendering roller 12, and the sand bristle block 21 and the calendering roller 12 are increased. The contact time of the sulfate attachments on the surface, at the same time, an ash suction groove 22 is opened on the curved surface and at the bottom of the sand bristle block 21. It falls into the ash suction tank 22, and under the action of suction, it is conducive to the falling off sulfate attachments and the sulfate attachments on the sand wool inside the sand wool block 21 to be sucked into the dust suction pipe 2 to further speed up the cleaning The rate of sulfate attachment.

[0046]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com