Design method and structure of steel sheet pile cofferdam with bed rock covered with thick pebble bed

A technology of steel sheet pile cofferdams and design methods, which is applied in the direction of foundation structure engineering, sheet pile walls, underwater structures, etc., can solve the problems of steel sheet pile deformation, influence, and damage to the waterproof performance and mechanical performance of steel sheet piles, and achieve The effect of improving utilization rate, reducing displacement and saving material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

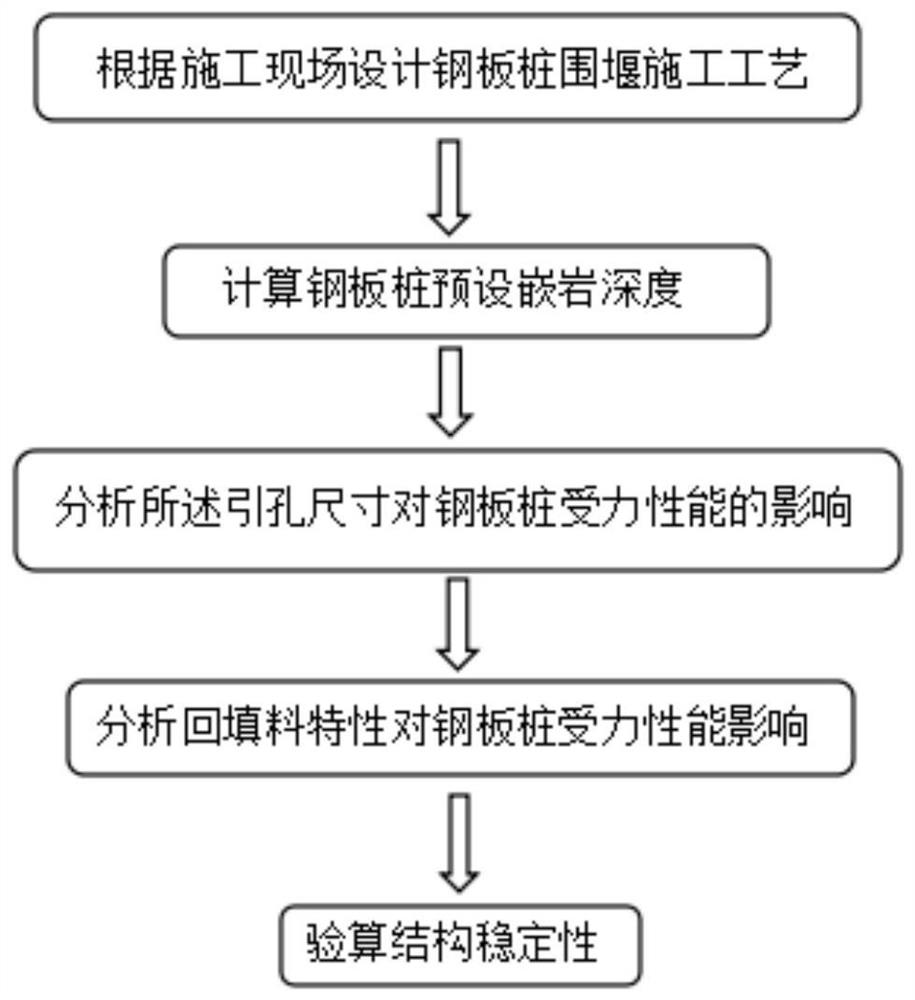

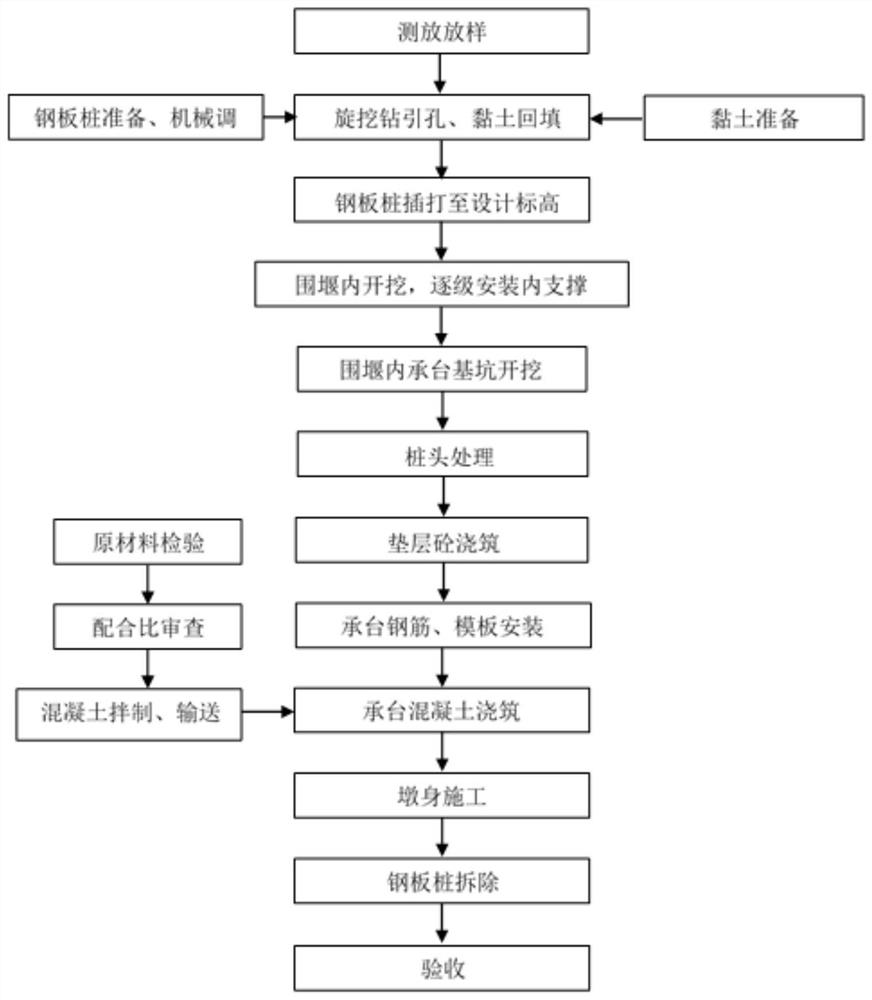

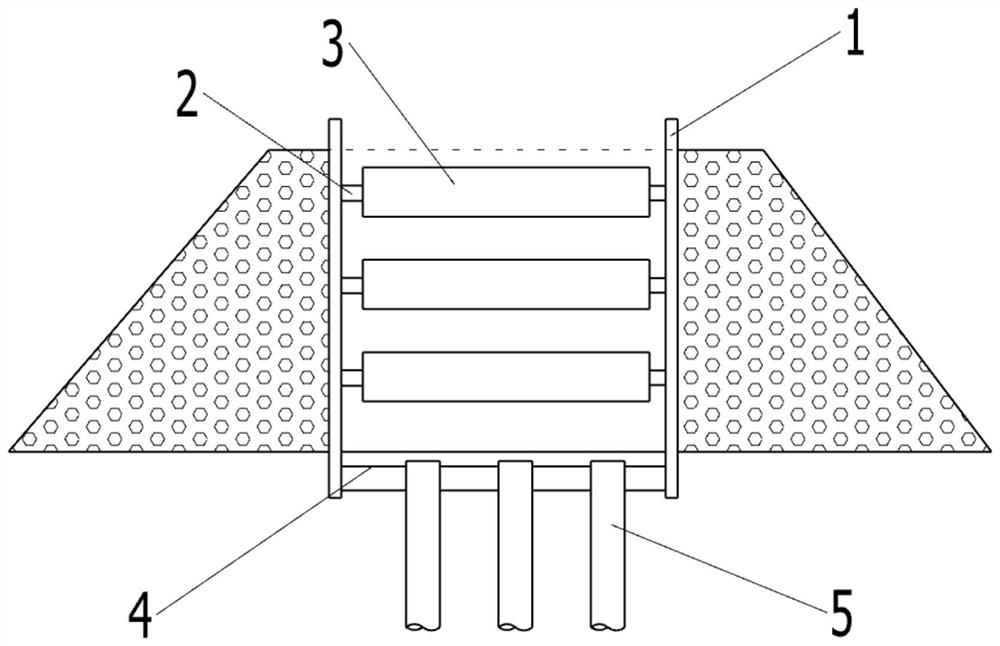

[0040] see Figure 1 to Figure 6 , The present invention provides a method for designing a cofferdam of steel sheet piles with thick pebble layers overlying bedrock, including:

[0041] S1: Design the construction process of the steel sheet pile cofferdam according to the construction site, and drill the lead holes through the drilling device 6 to install the steel sheet pile 1;

[0042] S2: Calculate the preset rock-socketing depth H of the steel sheet pile 1;

[0043]

[0044] Among them, H is the preset rock-socketing depth; σ 1 is the shear force of the pile body at the top surface of the bedrock; δ is the compressive coefficient of the bedrock; P is the standard value of the saturated uniaxial compressive strength of the bedrock; D is the diameter of the pile body in the rock-socketed section;

[0045] S3: analyze the influence of the size of the pilot hole on the mechanical performance of the steel sheet pile 1;

[0046] S4: Analyze the influence of backfill charac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com