Online verification device and method for PCCP broken wire acoustic monitoring device

A technology of monitoring device and verification device, which is applied in the direction of measuring device, preparation of test samples, processing of response signals of detection, etc., can solve the problems of commercial application and promotion of localized acoustic fiber optic monitoring system, adverse effects on commercialization and lack of inspection methods, etc. , to achieve the effect of improving the verification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

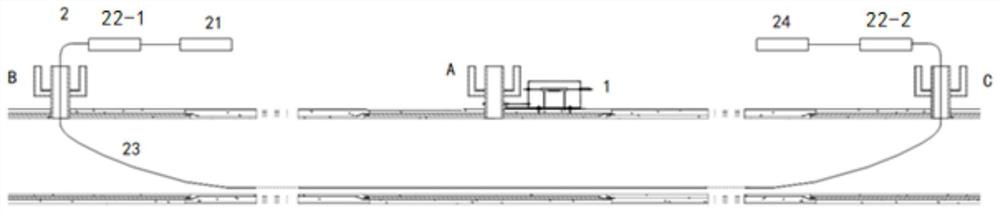

[0086] Example 2: as figure 1 As shown, the online verification method of the PCCP broken wire acoustic monitoring device provided by this embodiment includes:

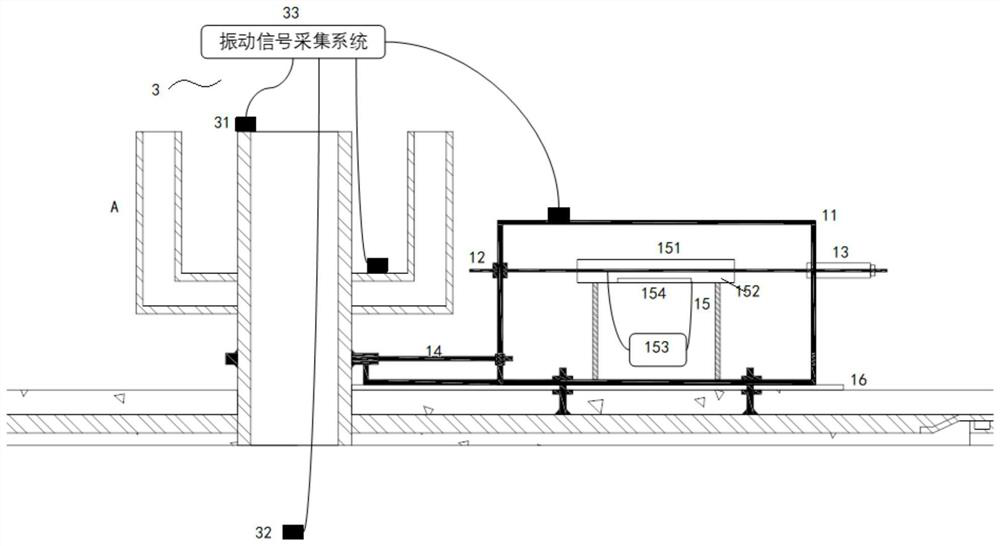

[0087] S1. Before the inspection, arrange the acoustic optical fiber 23 to be verified in the pipeline, and use the two exhaust valves B and C along the pipeline to exit the line and reserve a certain length for adjustment. Adjust the length of the optical cable; at least an exhaust valve well or maintenance well with an exhaust valve A should be included between the two outlet ports for arranging the simulated broken wire and the wave guide device 1.

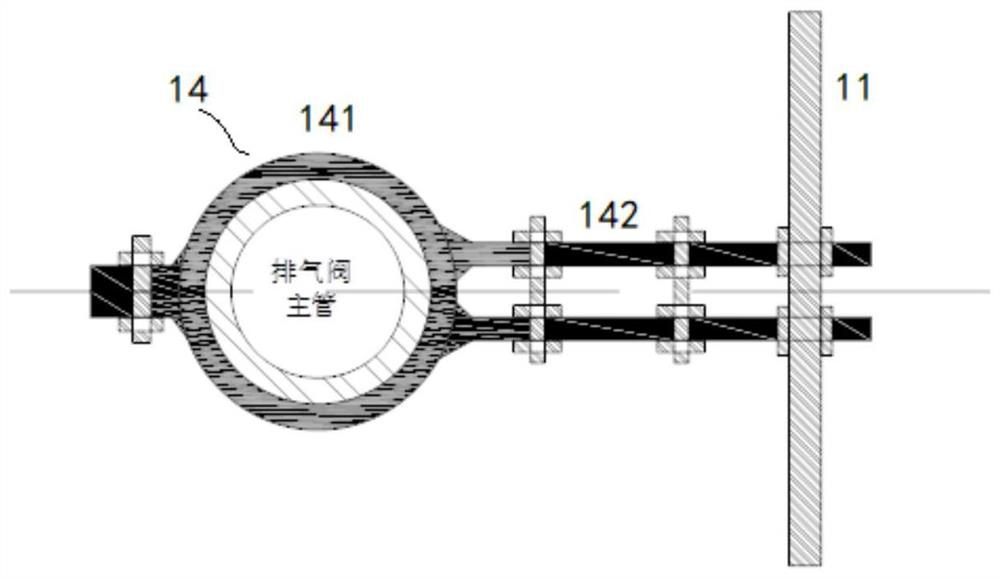

[0088] S2. During the inspection, the broken wire is simulated by simulating the broken wire and the wave guide device 1, and the mechanical vibration signal generated by the broken wire is transmitted into the steel pipe section (exhaust valve metal component) through the probe rod 14 and the anchor bolt, and is then affected by the sound. Fiber 23, vibration sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com