Ceramic, atomizing core and atomizer

An atomizer and atomizing core technology, which is applied to tobacco and other directions, can solve the problems of narrow firing range and poor thermal shock resistance, and achieve the effects of improving thermal shock resistance, improving performance and expanding firing range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present application also provides a method for preparing a ceramic, which is used to prepare and form the above-mentioned ceramic 10. The preparation method specifically includes the following steps:

[0040] S1: Obtain a ceramic substrate.

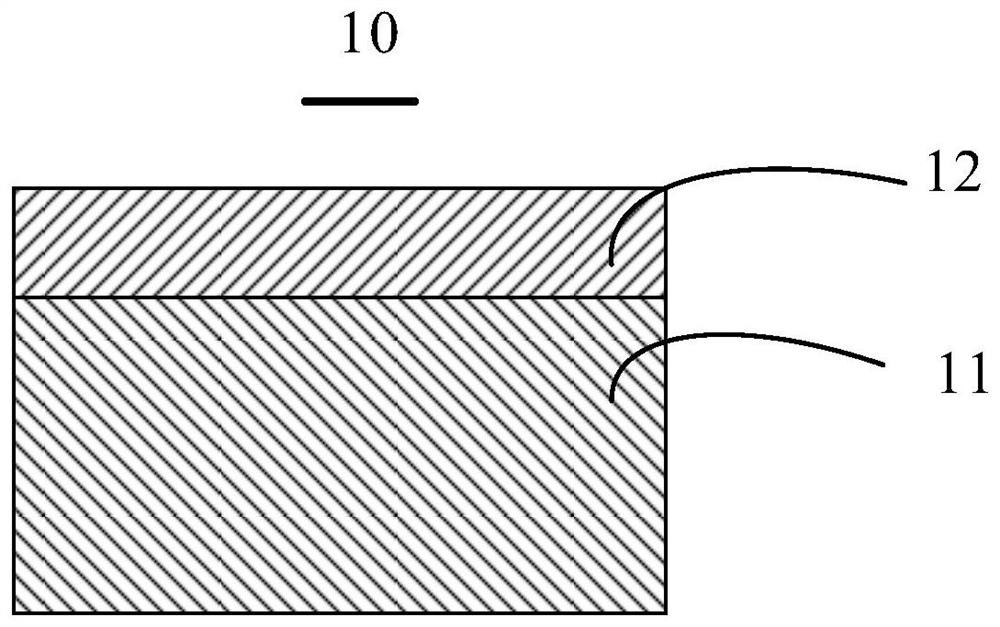

[0041] Specifically, a porous ceramic material can be used to directly prepare the ceramic substrate 11 according to specific design requirements, or a porous ceramic substrate 11 can be prepared by using a dense ceramic material to open pores. In this embodiment, the ceramic substrate 11 is made of a porous ceramic material. The shape of the ceramic substrate 11 is a rectangular parallelepiped.

[0042] S2: Prepare a modified layer on the surface of the ceramic substrate.

[0043] Specifically, on the surface of the cuboid-shaped ceramic substrate 11 prepared and formed in the above steps, the modification layer 12 is prepared and formed by a deposition process or a coating method. Optionally, a deposition process such as ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com