Smearing type color additive based on composite assembled particles and preparation method thereof

An additive and color technology, applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of limited color brightness and contrast, limited application, harmful to human body, etc., to improve brightness and contrast, and eliminate incoherent scattering. , rich and colorful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

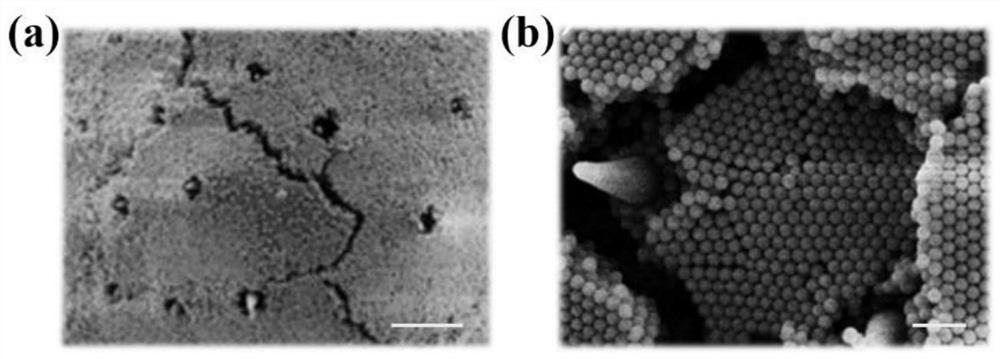

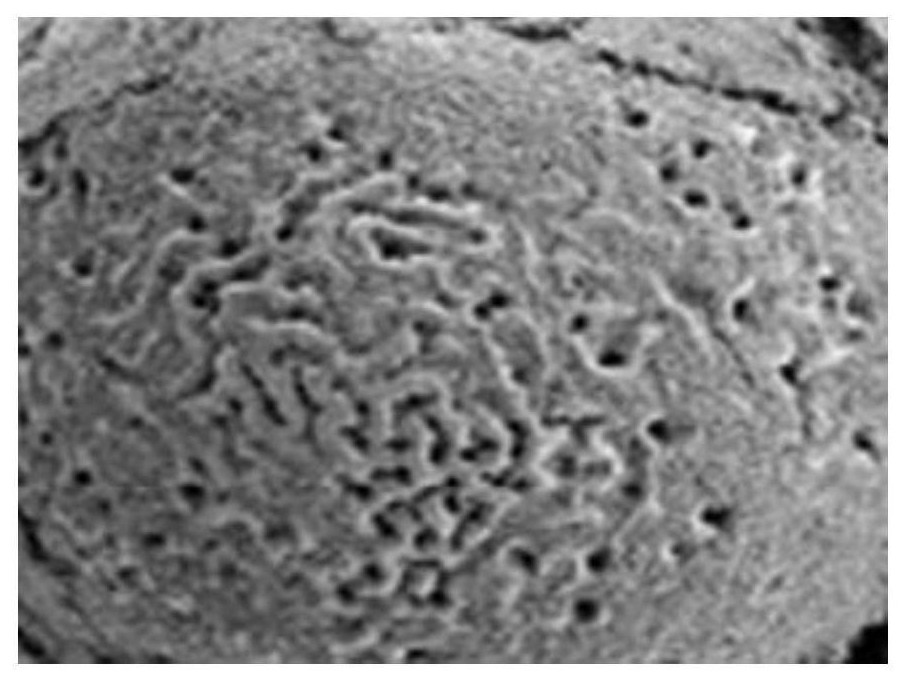

[0028] A smear-type color additive based on composite assembly particles using chrysanthemum pollen as raw material, the preparation process is as follows figure 1 The specific preparation steps are as follows:

[0029] S1, immerse chrysanthemum pollen in alcohol, obtain the pollen grain dispersion of chrysanthemum pollen after sufficient vibration, heat the pollen grain dispersion to completely volatilize the alcohol, and obtain dry chrysanthemum pollen grains with uniform size after sieving; collect chrysanthemum pollen grains in a crucible calcination in a deoxidized environment, the temperature of the muffle furnace was set to 400 °C, and the calcination time was 18 h to obtain a carbonized chrysanthemum pollen base (dark pollen base);

[0030] S2. Prepare silicon dioxide particles with a particle size of 240 nm, configure it into an alcohol dispersion of silicon dioxide nanoparticles with a mass concentration of 1%, fully ultrasonically disperse the silicon dioxide partic...

Embodiment 2

[0033] A kind of smear type color additive based on composite assembly particles using short ragweed pollen as raw material, the preparation process is as follows figure 1 The specific preparation steps are as follows:

[0034] S1. Immerse the short ragweed pollen in alcohol, obtain the pollen grain dispersion of short ragweed pollen after sufficient vibration, heat the pollen grain dispersion to make the alcohol completely volatilize, and obtain dry short ragweed pollen grains with uniform size after sieving; The chrysanthemum pollen grains were collected in a crucible and calcined in a deoxygenated environment. The temperature of the muffle furnace was set to 400°C and the calcination time was 18h to obtain a carbonized short ragweed pollen base (dark pollen base);

[0035] S2. Prepare silica particles with a particle size of 220 nm and configure it into an alcohol dispersion of silica nanoparticles with a mass concentration of 1%. Fully ultrasonically disperse the silica pa...

Embodiment 3

[0038] A smear-type color additive with composite structural color, the preparation process is as follows figure 1 The specific preparation steps are as follows:

[0039] S1, immerse chrysanthemum pollen in alcohol, obtain the pollen grain dispersion of chrysanthemum pollen after sufficient vibration, heat the pollen grain dispersion to completely volatilize the alcohol, and obtain dry chrysanthemum pollen grains with uniform size after sieving; collect chrysanthemum pollen grains in a crucible calcination in a deoxidized environment, the temperature of the muffle furnace was set to 400 °C, and the calcination time was 18 h to obtain a carbonized chrysanthemum pollen base (dark pollen base);

[0040] S2. Prepare two kinds of silica particles with a particle size of 220 nm and 240 nm, respectively configure them into an alcohol dispersion of silica nanoparticles with a mass concentration of 1%, fully ultrasonically disperse the silica particles uniformly, and firstly carbonize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com