Method for treating retained plutonium in waste organic phase in PUREX process

An organic phase and process technology, which is applied in the field of plutonium retention in the waste organic phase of the PUREX process, can solve the problems of difficult elution of uranium and plutonium, increased degradation products, and lack of competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The waste organic phase feed liquid obtained from the PUREX process in China's nuclear fuel reprocessing pilot plant is taken as the treatment object. The feed liquid is the waste organic phase with excess plutonium content obtained by post-processing uranium-plutonium separation and plutonium purification cycle, and the plutonium elution operation is carried out with dilute acid solution and tetravalent uranium solution respectively. Its main chemical composition is: 30% (volume percent) tributyl phosphate (TBP) and 70% (volume percent) hydrogenated kerosene, of which the plutonium content is 0.06g / L, the uranium content is 4.5g / L, and the nitric acid content is 0.3mol / L. The content of dibutyl phosphate (DBP) determined by anion chromatography is 0.9mmol / L, and the content of monobutyl phosphate (MBP) is 0.23mmol / L. According to the concentration of retained plutonium and uranium in the waste organic phase, the actual concentration of MBP may be inferred. Above 1 mmo...

Embodiment 2

[0056] The treatment method of this embodiment is the same as that of embodiment 1, except that the concentration of the NaOH solution in step (2) is 2M; the measurement results are shown in Table 1.

Embodiment 3

[0058] The treatment method of this embodiment is the same as that of embodiment 1, the difference is that the volume ratio of the waste organic phase and the water phase extraction liquid is 5:1 (other conditions are the same).

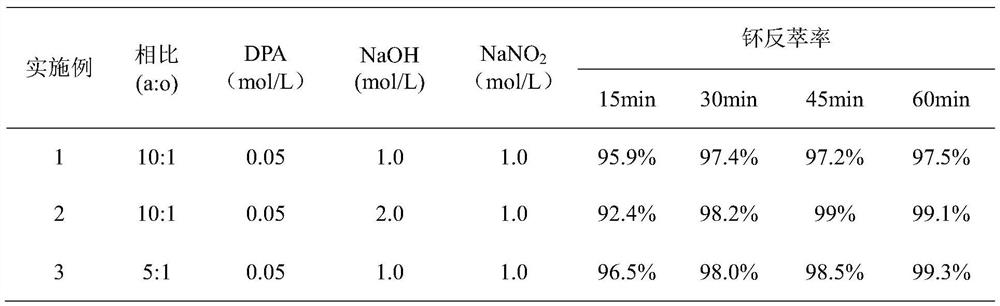

[0059] Table 1

[0060]

[0061] According to Table 1, DPA concentration and NaNO 2 When the concentrations are all the same, the increase of heating time is beneficial to the stripping of plutonium. After the heating time is greater than 45min, the stripping rate of Pu(IV) reaches equilibrium; on the premise that the two phases are still acidic, the residual acid in the organic phase The higher the neutralization percentage, the higher the Pu(IV) stripping rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com